Modified epoxy adhesive and preparing method thereof

An epoxy adhesive and modification technology, applied in epoxy resin adhesives, adhesives, adhesive additives, etc., can solve problems such as unusability, and achieve production cost savings, excellent roller peel strength, and easy availability of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

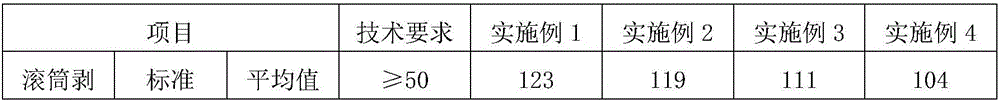

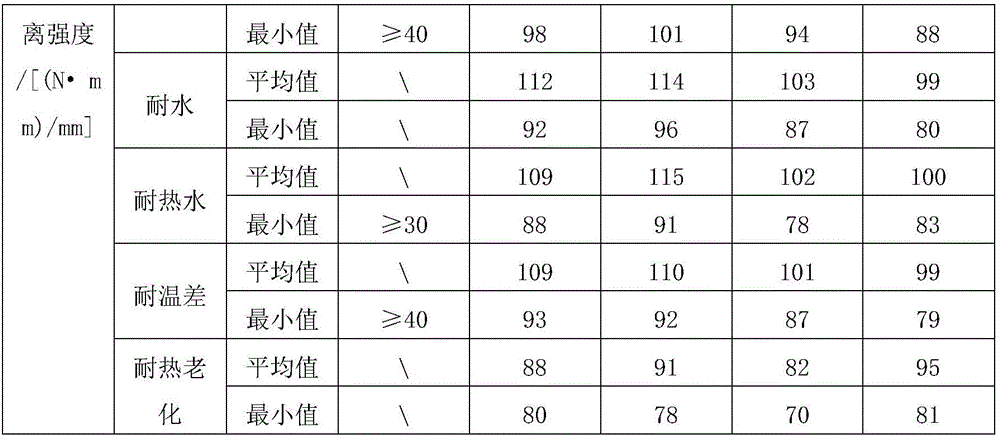

Examples

Embodiment 1

[0044] Formulation of group A: epoxy resin E-44: 10 parts, E-51: 22 parts; reactive diluent: 501 (propylene oxide butyl ether): 2 parts, 662 (glycerol triglycidyl ether): 5 parts, 692 (benzyl alcohol glycidyl ether): 3 parts; toughening agent: polyurethane modified epoxy resin (product source: Foshan Yameibo Chemical Co., Ltd. ZR100): 15 parts, core-shell rubber modified epoxy resin (Product source: ICAM-8627, Shenzhen Chou Chuang Applied Materials Co., Ltd.): 8 parts, epoxy-terminated liquid nitrile rubber (product source: Jiadida Chemical ETBN 1300X63): 5 parts; coupling agent: KH-560 ( γ-glycidyl ether propyl trimethoxysilane): 3 parts; nanocomposite materials: nano-silica: 0.5 parts, nano-titanium dioxide: 1.5 parts, calcium sulfate whiskers: 1 part; filler: active silica powder: 21 parts ; Auxiliaries: dispersant: 0.3 parts, wetting agent: 0.3 parts, anti-settling agent 0.1 parts, defoamer 0.3 parts; antioxidant: 1.5 parts; ultraviolet light stabilizer: 0.5 parts.

[004...

Embodiment 2

[0056] Formulation of group A: epoxy resin E-51: 20 parts, AG-80: 10 parts; reactive diluent 632 (1,6 hexanediol diglycidyl ether): 4 parts, 636 (trimethylolpropane shrink glyceryl ether): 2 parts, 669 (ethylene glycol diglycidyl ether): 2 parts; polyurethane modified epoxy resin toughener (source: Foshan Yameibo Chemical Co., Ltd. ZR101): 18 parts, core-shell rubber Modified epoxy resin (product source: ICAM-8611, Shenzhen Chuangchuang Applied Materials Co., Ltd.): 10 parts; coupling agent KH-560 (γ-glycidyl ether propyl trimethoxysilane): 2 parts; nano-titanium dioxide: 3 parts Parts, calcium sulfate whiskers: 2 parts; quartz powder: 9 parts; nitrogen-phosphorus halogen-free organic system flame retardant: 15 parts; dispersant: 0.3 parts, wetting agent: 0.3 parts, anti-settling agent 0.1 parts, Foam agent: 0.3 parts; Antioxidant: 2 parts.

[0057] A component preparation process:

[0058]Add epoxy resin, toughening agent and reactive diluent into the reaction vessel, then ...

Embodiment 3

[0068] Group A formulation: epoxy resin E-51: 30 parts; reactive diluent: 662 (glycerol triglycidyl ether): 5 parts, 748 (carbon twelve to carbon tetradecyl glycidyl ether): 3 Parts; polyurethane modified epoxy resin (source: Foshan Yameibo Chemical Co., Ltd. ZR101S): 13 parts, core-shell rubber modified epoxy resin (source: Shenzhen Chuangchou Applied Materials Co., Ltd. ICAM-8601): 12 parts ; Coupling agent KH-560 (γ-glycidyl ether propyl trimethoxysilane): 3 parts; nano-titanium dioxide: 2 parts, calcium sulfate whiskers: 3 parts; calcium carbonate powder: 26 parts; dispersant: 0.3 parts , Wetting agent: 0.3 parts, anti-settling agent 0.1 parts, defoamer 0.3 parts; antioxidant: 1.5 parts; ultraviolet light stabilizer: 0.5 parts.

[0069] The preparation process is the same as in Example 1.

[0070] B component formulation: amine curing agent: BASF (formerly German Koning) Versamid 150 polyamide: 40 parts, American Momentive EPIKURE 3125A polyamide: 15 parts, moisture and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com