Secondary curing epoxy resin adhesive for roads and bridges and preparation method thereof

An epoxy resin and secondary curing technology, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of fast curing speed, inability to rebond the mixture, long curing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

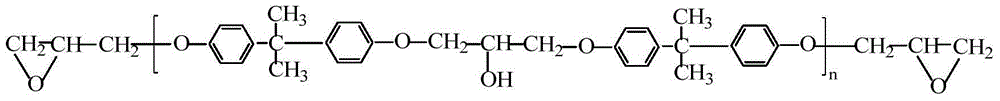

[0035] Example 1: Weigh 100 parts (parts by mass, the same below) hydroxyl-terminated polybutadiene liquid rubber (HTPB) (provided by Zibo Qilu Ethylene Chemical Co., Ltd.), and add 20 parts of toluene diisocyanate (TDI) (German BASF company ) and 0.5 parts of butyl ditin laurate (provided by Shanghai Yutian Chemical Co., Ltd.), start stirring, and gradually raise the temperature to 120 °C under the protection of nitrogen, and cool to room temperature after reacting for 2 hours to obtain isocyanate-terminated polybutylene Diene liquid rubber (TDI-HTPB-TDI).

Embodiment 2

[0036] Example 2: 10 parts of TDI-HTPB-TDI, 20 parts of polypropylene glycol (PPG-200) (provided by Jiangsu Haian Petrochemical Factory) and 0.2 parts of tetrabutylammonium iodide (TBAI) (Yixing Kailida Chemical Co., Ltd. Provided by the company) mixed evenly, heated to 160°C, reacted for 2 hours while stirring, and cooled at room temperature for 24 hours to obtain a modified hydroxyl-terminated polybutadiene liquid rubber toughening agent.

Embodiment 3

[0037] Example 3: Mix 10 parts of TDI-HTPB-TDI, 20 parts of polypropylene glycol (PPG-400) (provided by Jiangsu Haian Petrochemical Factory) and 0.2 parts of tetrabutylammonium iodide (TBAI), and heat to 160°C , Reacted for 2 hours while stirring, and cooled at room temperature for 24 hours to obtain a modified hydroxyl-terminated polybutadiene liquid rubber toughening agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com