Ultraviolet radiation and moisture dual-curing adhesive composition and application thereof

A UV radiation and dual curing technology, applied in adhesive types, conjugated diene adhesives, polyurea/polyurethane adhesives, etc., can solve the problem that shadow areas cannot be cured by UV light, and achieve high curing efficiency High, high cross-linking density, excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

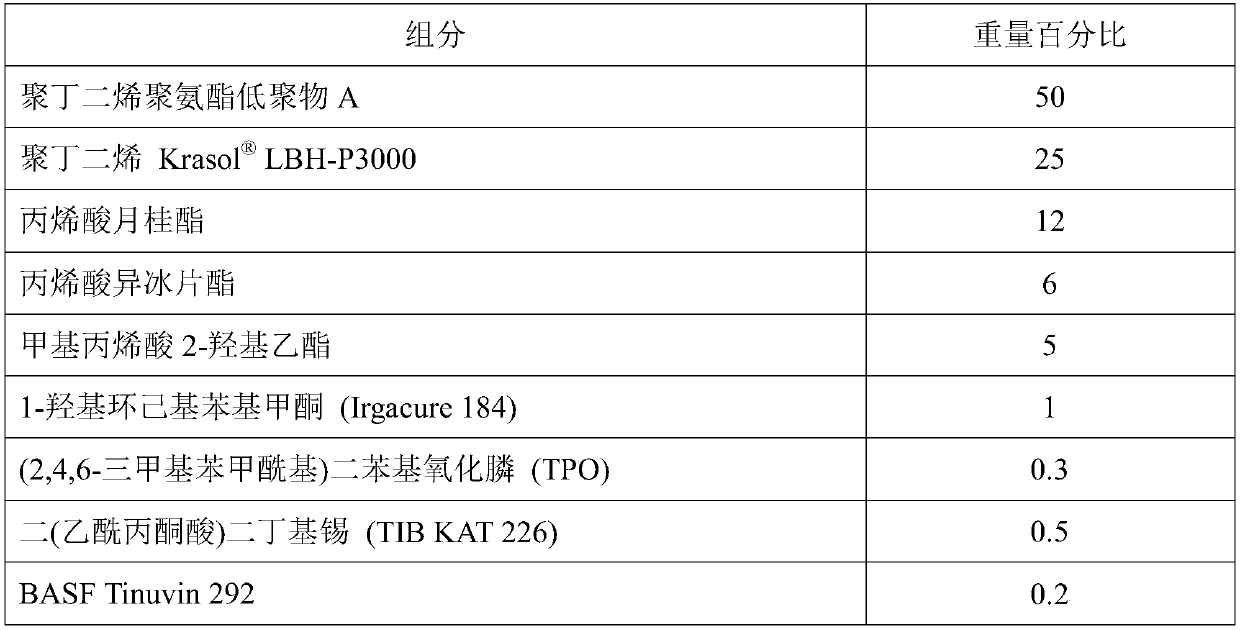

[0068] The formula of adhesive composition is as shown in table 1:

[0069] Table 1 The formula of adhesive composition

[0070]

[0071] At room temperature, weigh 50 parts by weight of polybutadiene polyurethane oligomer A with (meth)acryloxy and alkoxysilane functional groups, Krasol LBH-P3000 of 25 parts by weight, 12 parts by weight of Lauryl acrylate, 6 parts by weight of isobornyl acrylate and 5 parts by weight of 2-hydroxyethyl methacrylate were put into a stirring tank and stirred for about 60 minutes. Subsequently, weigh 1 part by weight of 1-hydroxycyclohexyl phenyl ketone (Irgacure 184), 0.3 part by weight of (2,4,6-trimethylbenzoyl) diphenylphosphine oxide (TPO), 0.5 parts by weight of di(acetylacetonate)dibutyltin (TIB KAT226) and 0.2 parts by weight of BASF Tinuvin 292 were also put into the stirred tank and continued to stir for about 60 minutes. After mixing evenly, filter and let it stand naturally for defoaming. During the entire feeding and stirring p...

Embodiment 2-5

[0089] The adhesive compositions of Examples 2-5 were prepared in a similar manner to Example 1. See Table 6 for the formula, specific process conditions, and UV curing and moisture curing properties of the adhesive composition of Examples 2-5. The changes in optical properties before and after aging are shown in Table 7.

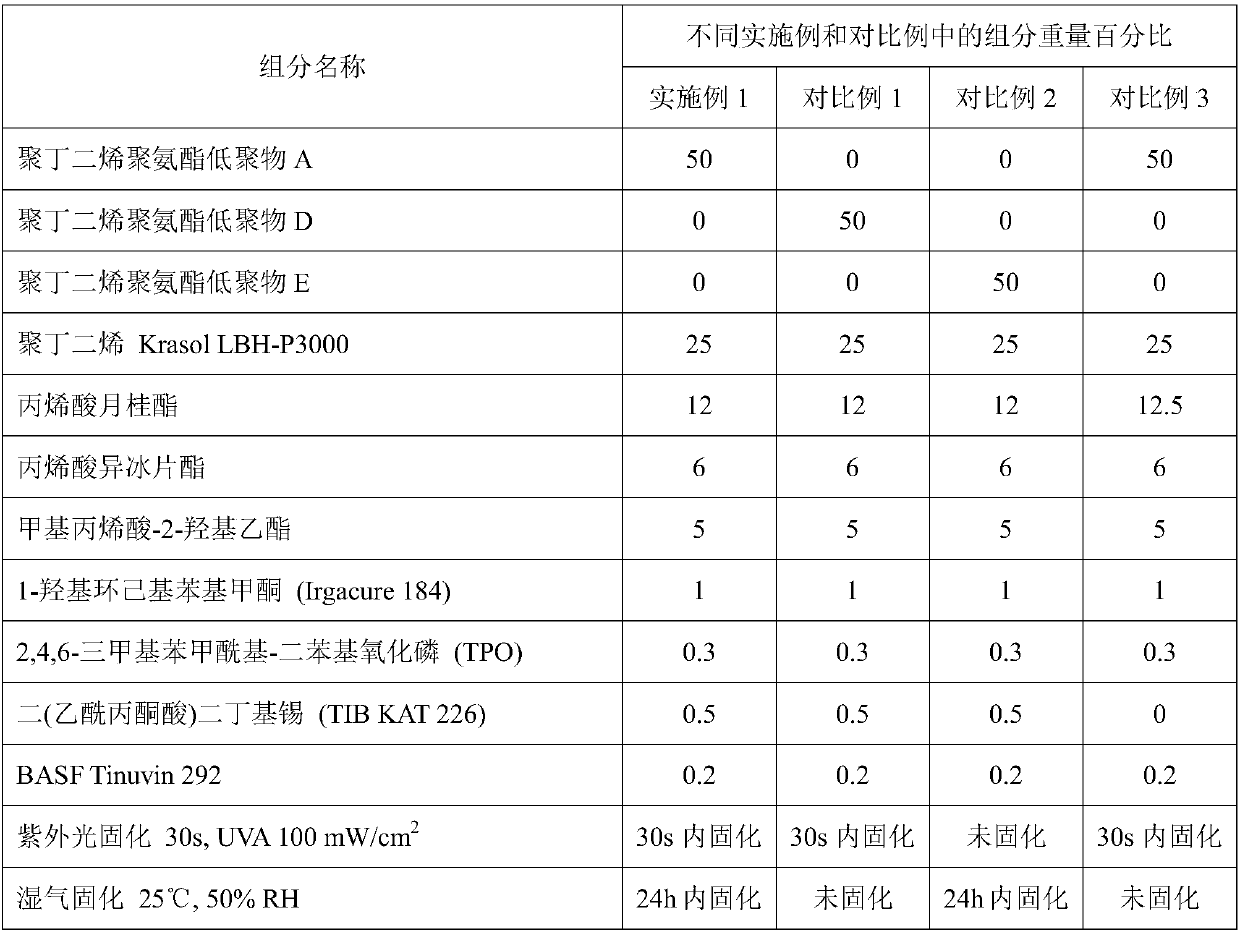

[0090] Table 4 Example 1 and Comparative Examples 1-3 Adhesive Composition Formulation and UV Curing and Moisture Curing Properties

[0091]

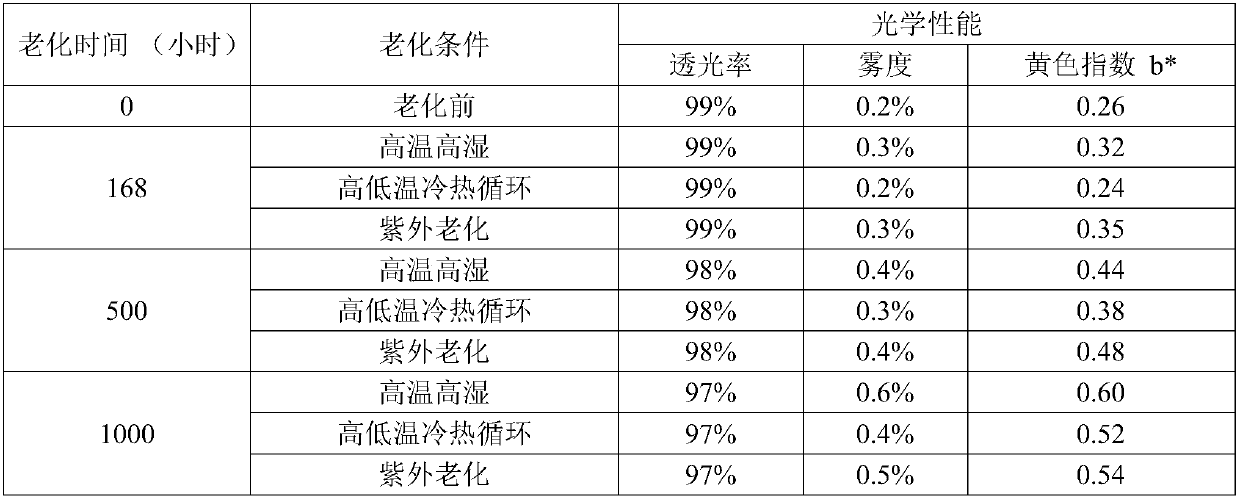

[0092] Table 5 Comparison of optical properties before and after aging in comparative examples 1-3

[0093]

[0094] Table 6 Example 2-5 Adhesive composition formula, specific process conditions and UV curing and moisture curing properties

[0095]

[0096] Table 7 Comparison of optical properties before and after aging in Examples 2-5

[0097]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com