Electrolyte-resistant rubber solution as well as preparation method and electrolyte-resistant rubber tape thereof

A technology of rubber glue and electrolyte, which is applied in the direction of rubber derivative glue, adhesive, film/sheet adhesive, etc., can solve problems such as potential safety hazards, loss of viscosity, corrosion and penetration of electrolyte, etc., to improve bonding performance, Effect of improving viscosity and improving initial adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

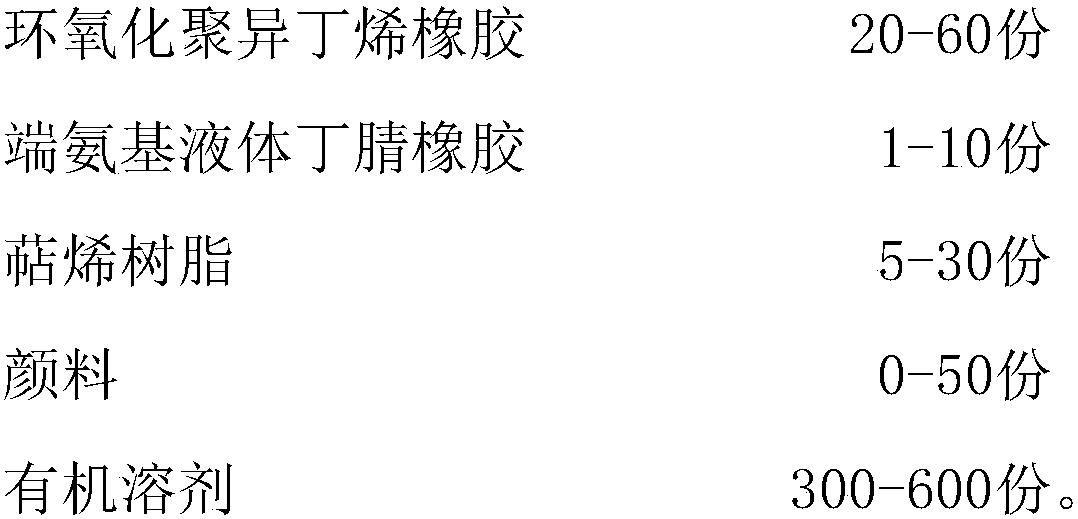

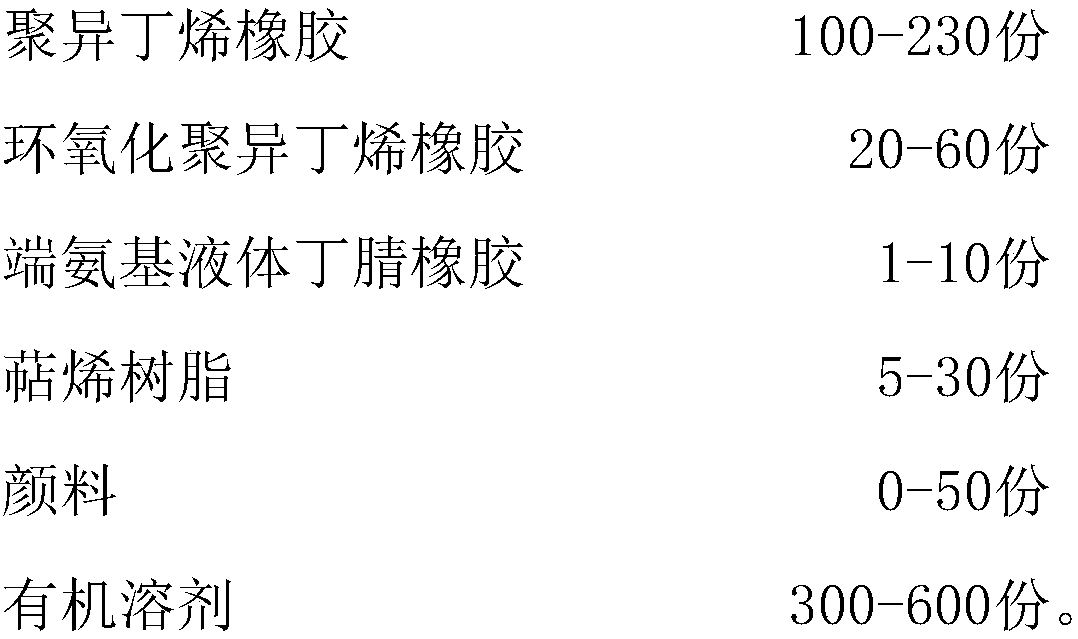

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of electrolyte-resistant rubber glue, comprising the following steps: (1) 50 parts by weight of polyisobutylene rubber A, 100 parts by weight of polyisobutylene rubber B, 40 parts of epoxidized polyisobutylene rubber, 5 parts of amino-terminated liquid Nitrile rubber and 10 parts of terpene resin are dissolved in 500 parts of organic solvent at a temperature of 70 ° C to dissolve it into a uniform and bright glue;

[0032] (2) Add 20 parts of pigments into the glue in the step (1), and stir evenly to prepare the electrolyte-resistant rubber glue.

[0033] The weight average molecular weight of the polyisobutylene rubber A is 400,000; the weight average molecular weight of the polyisobutylene rubber B is 95,000.

[0034] The epoxidized polyisobutylene rubber is prepared by oxidation of polyisobutylene rubber with a weight average molecular weight of 1000 by organic acid.

[0035] The organic acid is acetic acid.

[0036] The molar ratio of the doub...

Embodiment 2

[0042] A preparation method of electrolyte-resistant rubber glue, comprising the following steps: (1) 45 parts by weight of polyisobutylene rubber A, 102 parts by weight of polyisobutylene rubber B, 48 parts of epoxidized polyisobutylene rubber, 4 parts of amino-terminated liquid Nitrile rubber and 20 parts of terpene resin are dissolved in 400 parts of organic solvent at 70°C to form uniform yellowish glue;

[0043] (2) Add 30 parts of pigments into the glue in the step (1), and stir evenly to prepare the electrolyte-resistant rubber glue.

[0044] The weight average molecular weight of the polyisobutylene rubber A is 395,000; the weight average molecular weight of the polyisobutylene rubber B is 98,000.

[0045] The epoxidized polyisobutylene rubber is prepared by oxidation of polyisobutylene rubber with a weight average molecular weight of 1200 by organic acid.

[0046] Described organic acid is peroxybenzoic acid.

[0047] The molar ratio of the double bond in the epoxid...

Embodiment 3

[0053] A preparation method of electrolyte-resistant rubber glue, comprising the following steps: (1) 30 parts by weight of polyisobutylene rubber A, 150 parts by weight of polyisobutylene rubber B, 20 parts of epoxidized polyisobutylene rubber, 1 part of amino-terminated liquid Nitrile rubber and 5 parts of terpene resin are dissolved in 300 parts of organic solvent at 60°C to form uniform yellowish glue;

[0054] The weight average molecular weight of the polyisobutylene rubber A is 420,000; the weight average molecular weight of the polyisobutylene rubber B is 90,000.

[0055] The epoxidized polyisobutylene rubber is prepared from polyisobutylene rubber with a weight average molecular weight of 500 through organic acid oxidation.

[0056] Described organic acid is m-chloroperoxybenzoic acid.

[0057] The molar ratio of the double bond in the epoxidized polyisobutylene rubber to the organic acid is 1:0.9.

[0058] The softening point of the terpene resin is 100° C., and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com