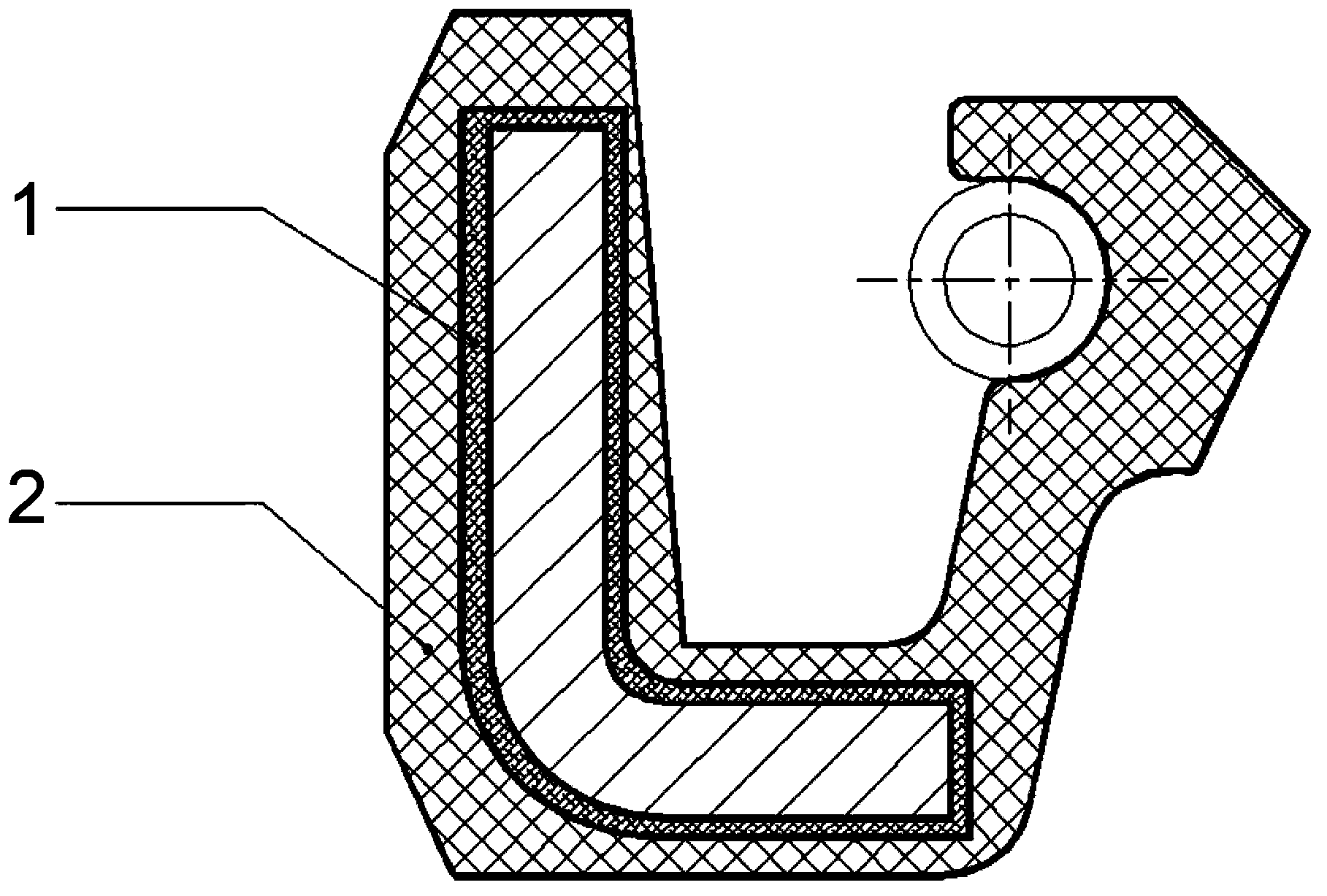

Large-scale hydrogenated nitrile butadiene skeleton oil seal, and preparation method and application thereof

A technology of hydrogenated nitrile butadiene, skeleton oil seal, applied in the direction of adhesive type, rubber-derived adhesive, adhesive additive, etc., can solve the problem of unguaranteed bonding reliability, and achieve good bonding reliability and lip pressure change. Small, the effect of improving the production qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment S-1

[0071] Example S-1: The adhesive rubber mixed rubber was thinly passed on an open mill into 0.5-1.0 mm thin slices, which were divided into thin strips of fixed width. If it is an internal skeleton oil seal, wrap the pre-treated skeleton repeatedly with thin rubber strips. If it is an outer frame oil seal, attach the thin rubber strip to the surface of the frame coated with adhesive.

Embodiment S-2

[0072] Example S-2: The adhesive glue was thinly passed on an open mill into 0.5-1.0 slices, cut into pieces and added to the mixer with methyl ethyl ketone, soaked for 3 to 5 hours statically, and stirred for 2 to 4 hours to obtain a uniform adhesive glue. The mass ratio of adhesive glue and methyl ethyl ketone is 1:4 to 4.5. The obtained adhesive glue was coated on the pretreated frame, dried naturally and dried at 80°C for 10 minutes.

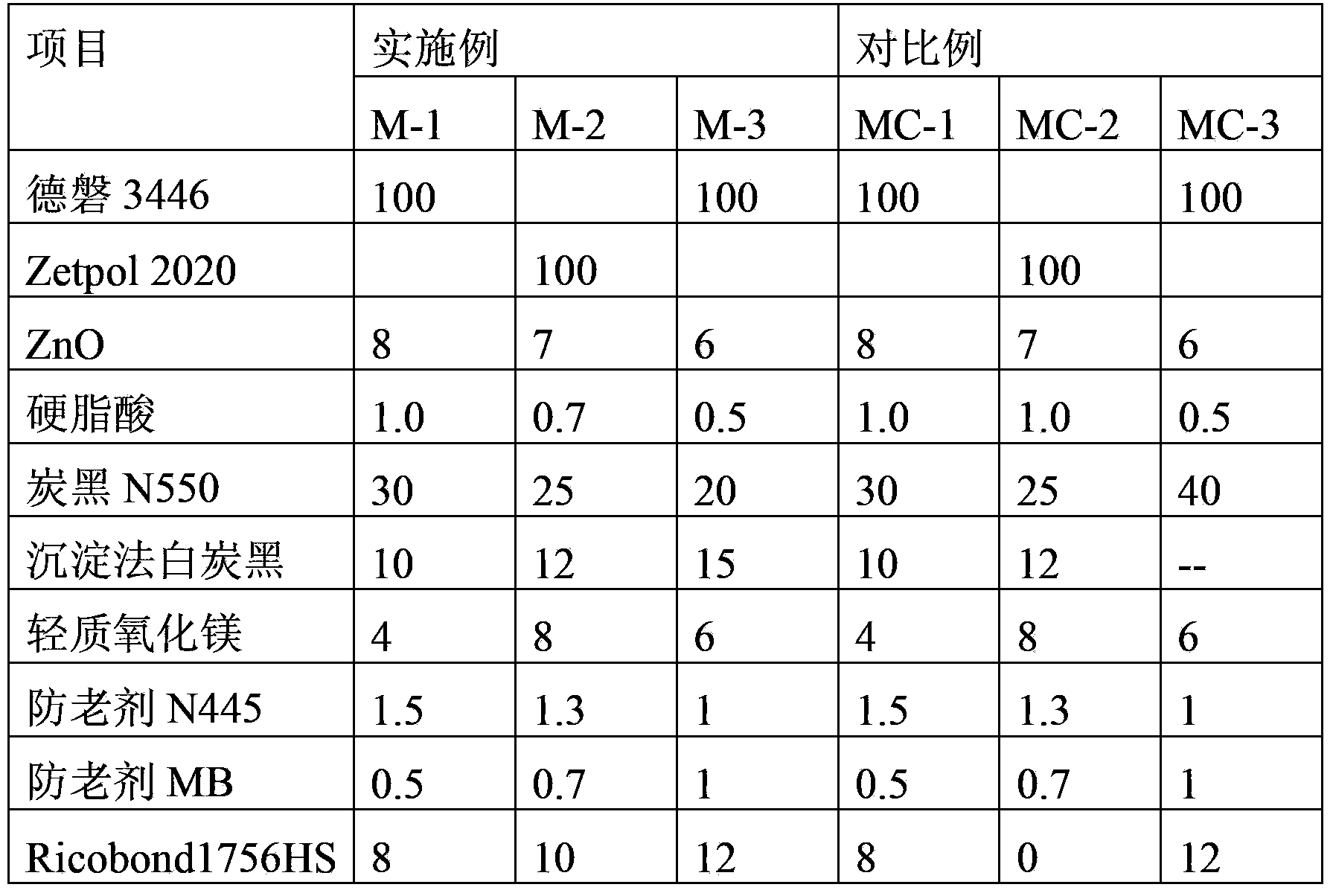

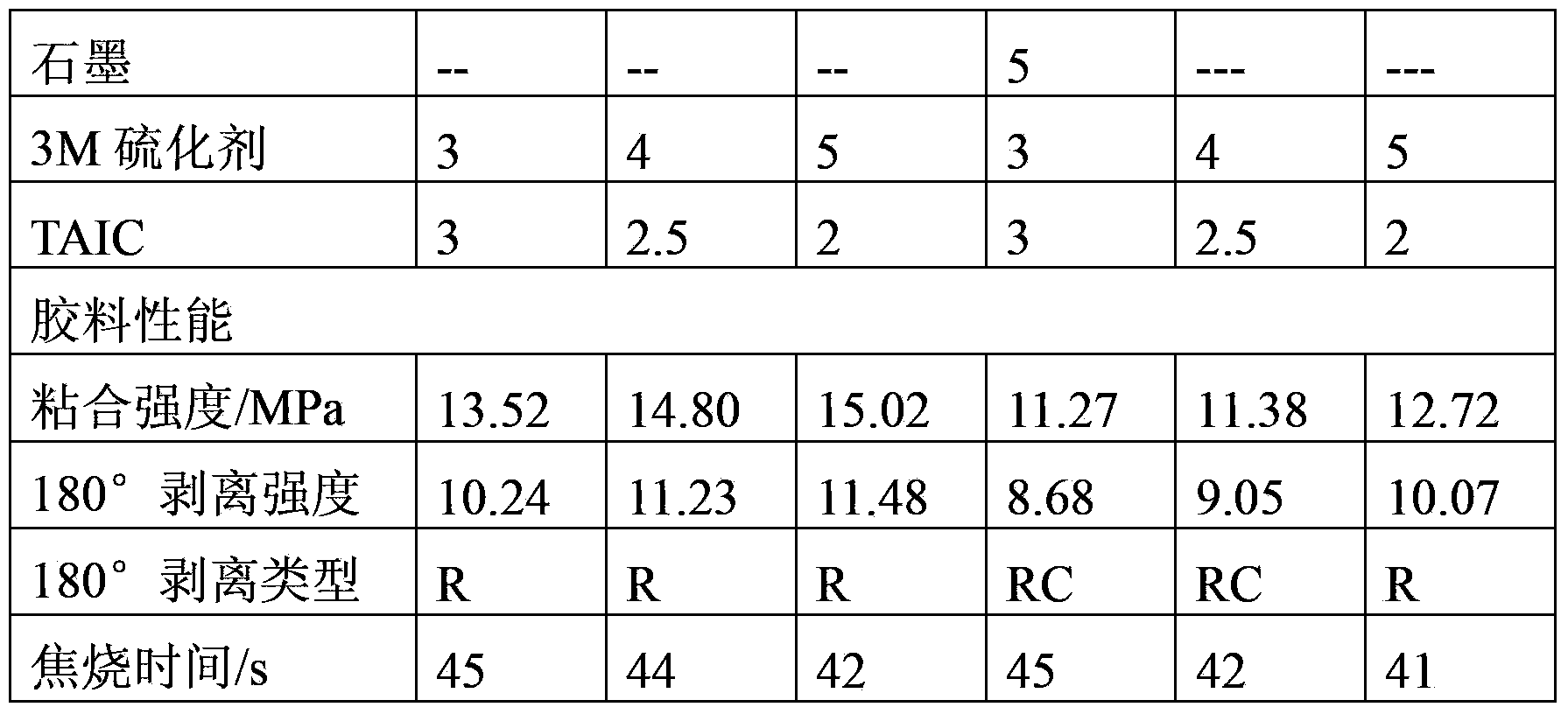

[0073] The preparation and product performance of large-scale oil seal products are shown in Table 2 in Examples 1 to 3 and Comparative Examples 1 to 4. In addition, the lip glue is produced on an open mill and a thin strip of 0.5 to 1.0 mm is produced on the extruder. Adhesive strips. Cover or wrap the frame with adhesive glue on a thin strip. Put the skeleton and lip rubber strips into a vulcanizing mold, and vulcanize on a flat vulcanizer at 145~155℃ for 15~25 minutes. After trimming the flash, after vulcanizing at 130~150℃ for 2~4 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com