Heat-activated adhesive sheet

An adhesive sheet and adhesive technology, applied in the direction of adhesive, film/sheet release liner, film/sheet adhesive, etc., can solve the problem of difficult filming, achieve low adhesive force and improve yield , the effect of high adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

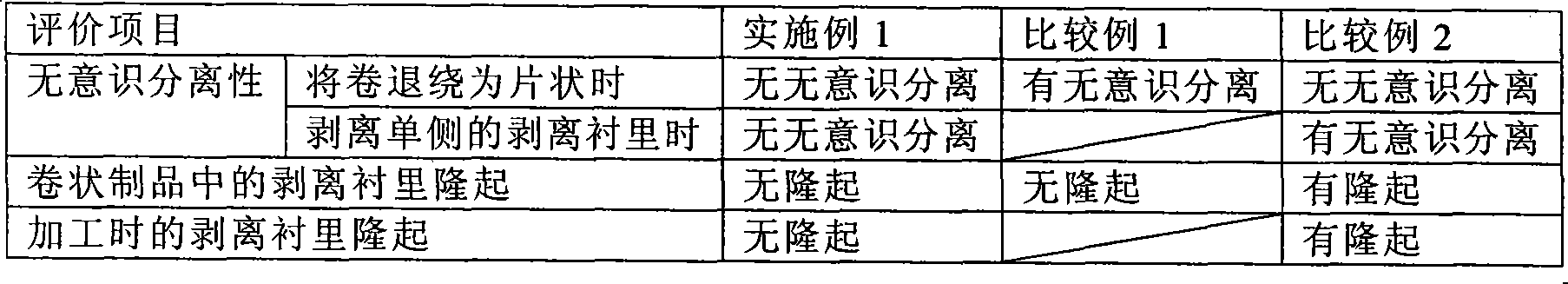

Embodiment 1

[0054] 10 parts by weight of styrene-butadiene-styrene block copolymer (manufactured by Asahi Kasei Chemical Co., Ltd., Asapuren T430 (5 parts by weight), Asapuren T420 (5 parts by weight)), hydrogenated petroleum resin (Arakawa Chemical Industry Co., Ltd. ; Alcon M115) 10 parts by weight, hydrogenated petroleum resin (manufactured by HERCULES; Picotex #120) 2.5 parts by weight, bisphenol anti-aging agent (Ouchi Shinko Chemical Industry Co., Ltd.; Nokrac NS-6) 0.2 parts by weight, double 0.1 weight part of phenolic antiaging agent (Ouchi Xinxing Chemical Industry Co., Ltd.; ノクラック MB) is uniformly dissolved with 22 weight parts of toluene and 0.8 weight part of isopropanol, and the adjustment solid content is 50 weight % to obtain the heat-adhesive sheet. Solution of hot adhesive composition.

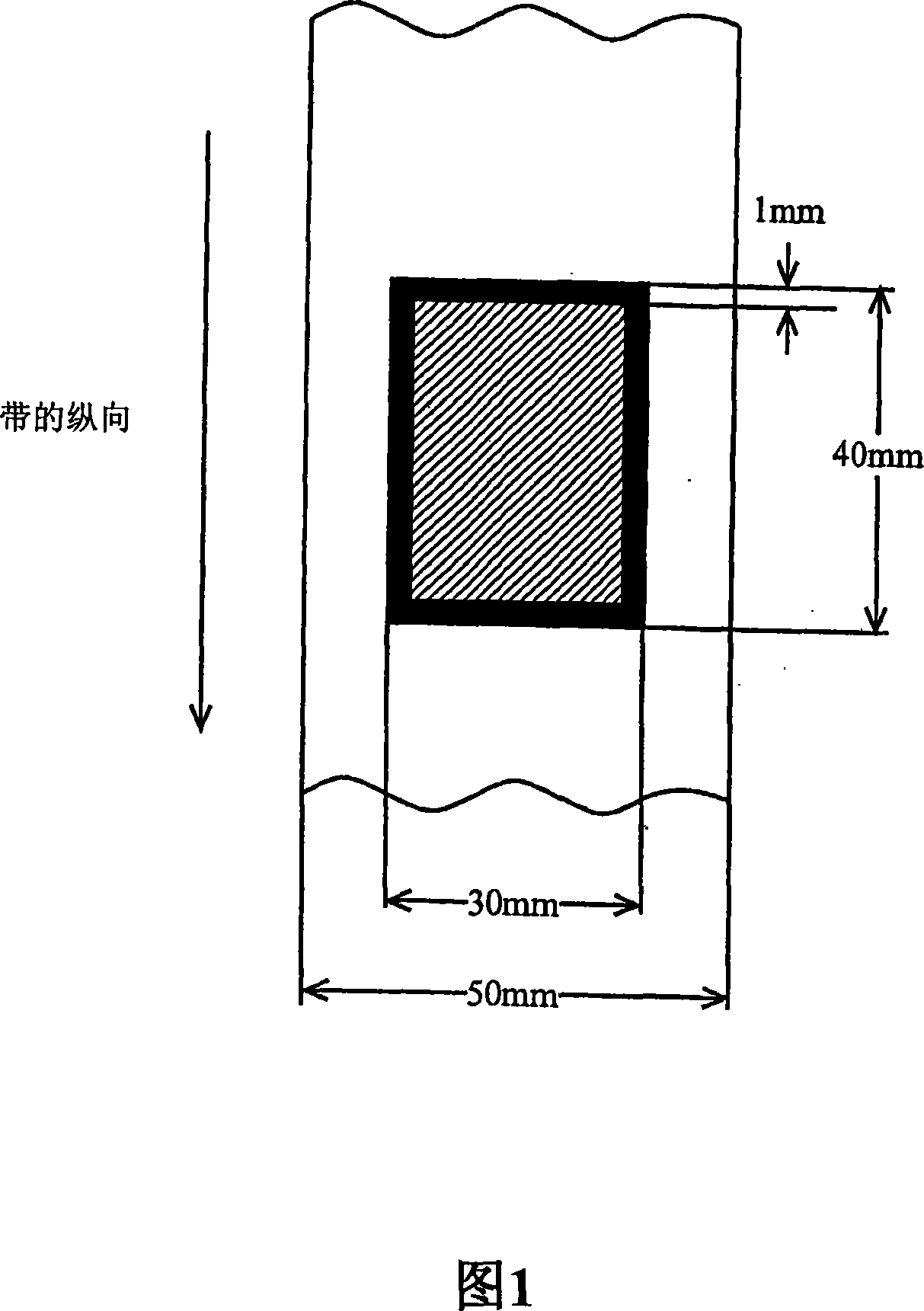

[0055] Then, the solution of the obtained thermal adhesive composition was applied to a substrate having a polyethylene terephthalate film (thickness: 75 μm), and a silicone-based releas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com