Pressure-sensitive adhesive compositions, pressure-sensitive adhesive sheets, and double-sided pressure-sensitive adhesive tapes

A composition, adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, film/flake adhesives, etc., which can solve the reduction of durability, use limitation, adhesion reduction, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0241] (Preparation of Adhesive Composition)

[0242] To 100 parts by weight of the solution (30% by weight) of the above-mentioned acrylic polymer (A), add 20 parts by weight of the solution (50% by weight) of the above-mentioned acrylic oligomer (a), 2 parts by weight of the above-mentioned ionic Liquid (1), 0.1 parts by weight of 1,3-bis(N,N-diglycidylaminomethyl)cyclohexane (manufactured by Mitsubishi Gas Chemical Co., Ltd., TETRAD-C) as a crosslinking agent at 25°C Mix and stir for about 1 minute to prepare an acrylic adhesive solution (1).

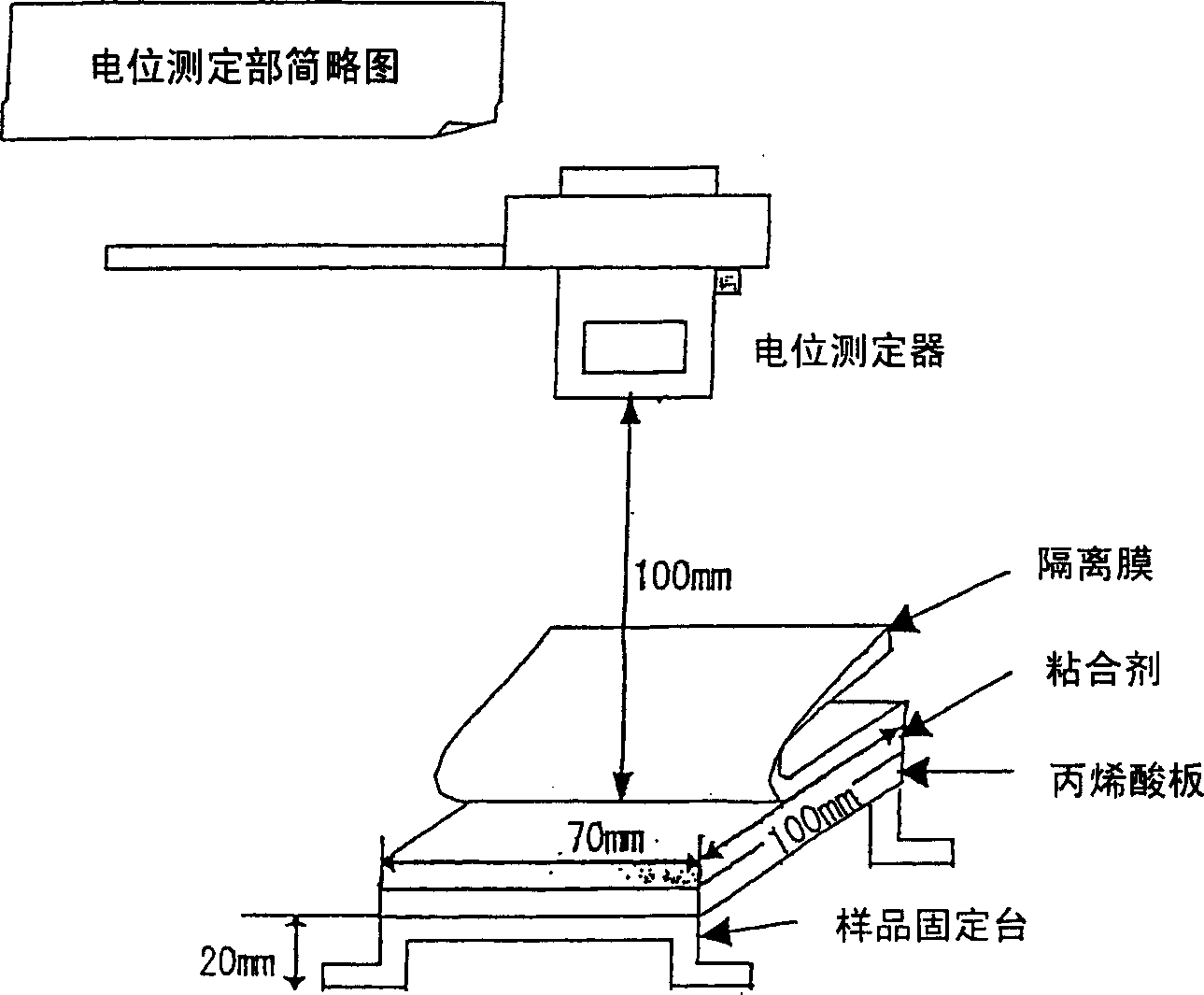

[0243] (production of adhesive sheet)

[0244] Apply the above-mentioned acrylic adhesive solution (1) on the silicone-treated surface of a polyethylene terephthalate film with a thickness of 38 μm that has been silicone-treated on one side, and heat at 130° C. for 3 minutes , forming an adhesive layer with a thickness of 25 μm. Next, the silicone-treated side of a polyethylene terephthalate film having a thickness of 50 μm that h...

Embodiment 2

[0246] (Preparation of Adhesive Composition)

[0247] To 100 parts by weight of the solution (30% by weight) of the above-mentioned acrylic polymer (A), add 20 parts by weight of the solution (50% by weight) of the above-mentioned acrylic oligomer (a), 2 parts by weight of the above-mentioned ionic Liquid (2), 0.1 parts by weight of 1,3-bis(N,N-diglycidylaminomethyl)cyclohexane (manufactured by Mitsubishi Gas Chemical Co., Ltd., TETRAD-C) as a crosslinking agent, at 25°C Mix and stir for about 1 minute to prepare an acrylic adhesive solution (2).

[0248] (production of adhesive sheet)

[0249] A pressure-sensitive adhesive sheet was produced in the same manner as in Example 1, except that the above-mentioned acrylic pressure-sensitive adhesive solution (2) was used instead of the above-mentioned acrylic pressure-sensitive adhesive solution (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com