High-intensity epoxy shell adhesive and preparation method thereof

An epoxy shell, high-strength technology, applied in the direction of epoxy resin glue, novolac epoxy resin adhesive, adhesive, etc., can solve the problems of poor processability and high viscosity of epoxy resin system, and achieve excellent rigidity , low viscosity, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

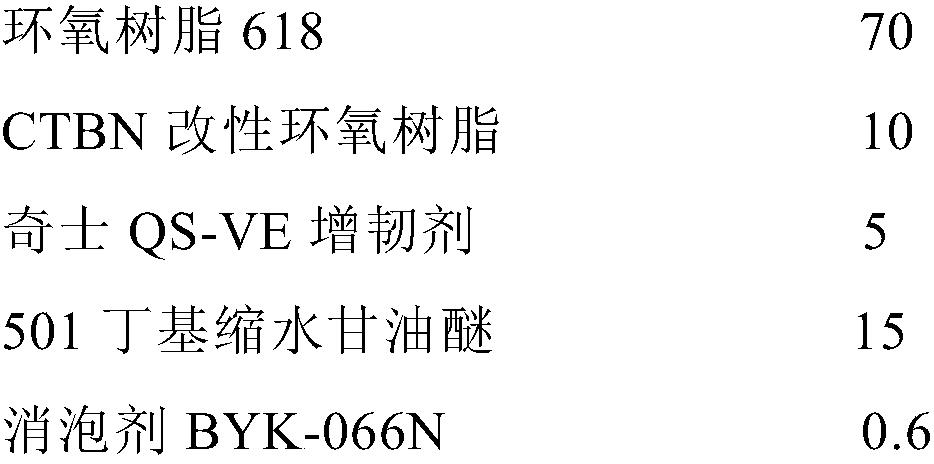

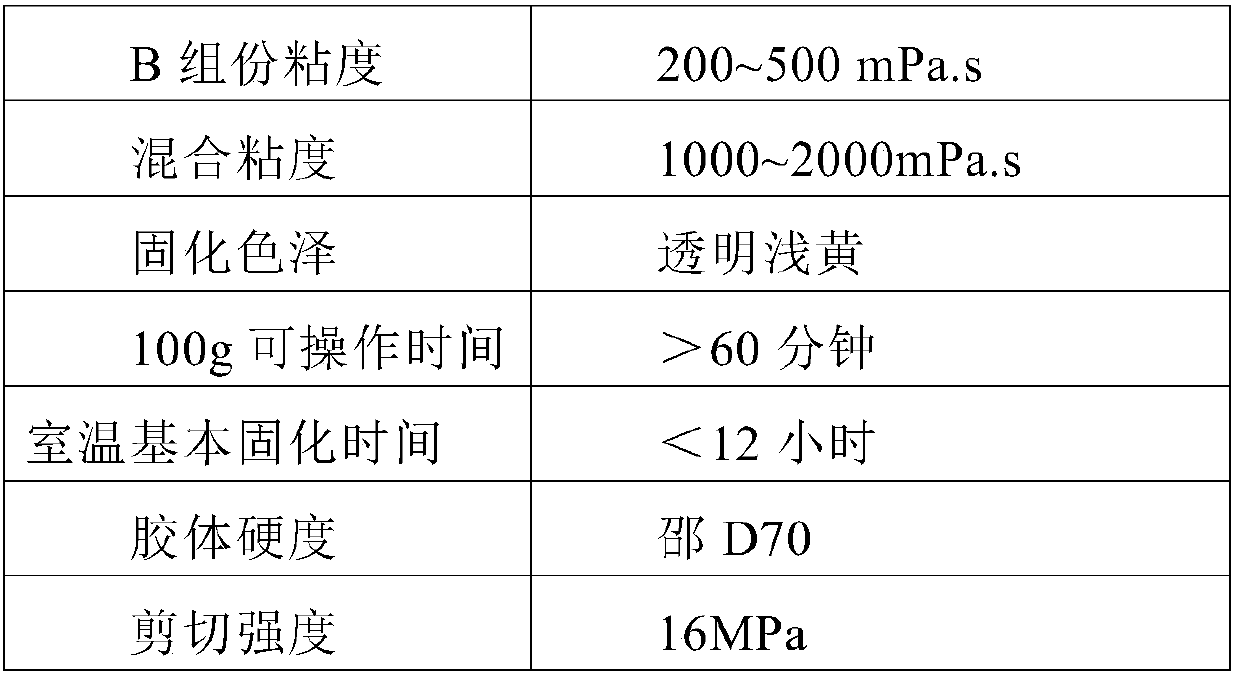

[0036] A high-strength epoxy shell glue and a preparation method thereof, the method comprising the following steps:

[0037] First component preparation method

[0038]

[0039] (1) Put epoxy resin 618 and CTBN modified epoxy resin required by the formula into a constant temperature oven at 60°C for about 3 hours.

[0040] (2) Then add the required epoxy resin 618, CTBN modified epoxy resin, and QS-VE into the reaction kettle together, then add the required 501 diluent, turn on the stirring and start stirring, and the stirring time is about 1 hour.

[0041] (3) Finally, add the required amount of defoamer BYK-066N and continue stirring for about 15 minutes.

[0042] (4) Check the performance and various indicators of the adhesive.

[0043] (5) Weigh and pack after passing the inspection.

[0044] Second component preparation method

[0045] Polyetheramine 80

[0046] 1,2-cyclohexanediamine 17

[0047] Coupling agent KH-550 3

[0048] (1) Put the polyetheramine curin...

Embodiment 2

[0055] A high-strength epoxy shell glue and a preparation method thereof, the method comprising the following steps:

[0056] First component preparation method

[0057]

[0058] (1) Put epoxy resin 618 and liquid nitrile rubber required by the formula into a constant temperature oven at 60°C for about 3 hours.

[0059] (2) Then add the required epoxy resin 618, liquid nitrile rubber, and dibutyl phthalate into the reaction kettle, then add the required 512 diluent, turn on the stirring and start stirring, and the stirring time is about 1 hour.

[0060] (3) Finally, add the required amount of defoamer BYK-A530 and continue stirring for about 15 minutes.

[0061] (4) Check the performance and various indicators of the adhesive.

[0062] (5) Weigh and pack after passing the inspection.

[0063] Second component preparation method

[0064]

[0065] (1) Put the polyetheramine curing agent EC-302, modified fat JH-5280 curing agent, alicyclic amine EC-201 curing agent and th...

Embodiment 3

[0071] A high-strength epoxy shell glue, when used, the first component and the second component are mixed at a weight ratio of 2-4:1, and the first component is prepared by using the following raw materials in parts by weight: epoxy Resin 50, active toughening agent 5, diluent 3, defoamer 0.5, the second component is prepared from the following raw materials in parts by weight: toughening curing agent 30, hardening curing agent 10, coupling agent 0.3.

[0072] The epoxy resin is amino tetrafunctional epoxy resin, the active toughening agent is carboxyl-terminated liquid nitrile rubber modified epoxy resin, the diluent is benzyl glycidyl ether, and the defoamer is corn oil. The toughening curing agent is an aromatic polyfunctional acid anhydride. The hardening and curing agent is polyetheramine. The coupling agent is γ(2,3-glycidoxy)propyltrimethoxysilane.

[0073] The preparation method of high-strength epoxy shell adhesive adopts the following steps:

[0074] (1) Prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com