Flip chip bottom filling adhesive with normal temperature rapid capillary fluidity and rapid repairability

An underfill, flip-chip technology, applied in adhesives, epoxy resins, rubber-derived adhesives, etc., can solve the problems of reduced connection reliability, difficulty in repairing and removing glue, poor rework efficiency, etc. Laminide toughness, good connection reliability, and the effect of increasing connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The raw material components and dosages of the underfill provided in Examples 1-5 and Comparative Examples 1-2 are shown in Table 1 below.

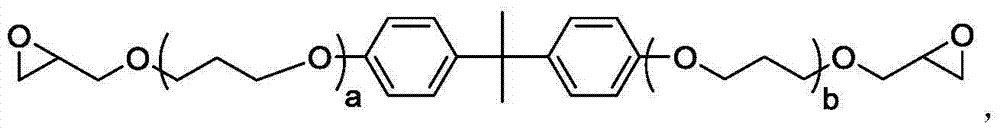

[0041] In an embodiment, in order to obtain representative data, bisphenol A type epoxy resin is selected E51 (embodiment 1,5, comparative example 1,2), E54 (embodiment 4); Novolak epoxy resin is selected F51 (implementation) Example 3), F44 (embodiment 4), the aliphatic epoxy resin is selected Dow DER 736 (embodiment 2), but the present invention is not limited thereto.

[0042] Preparation:

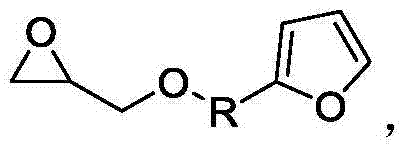

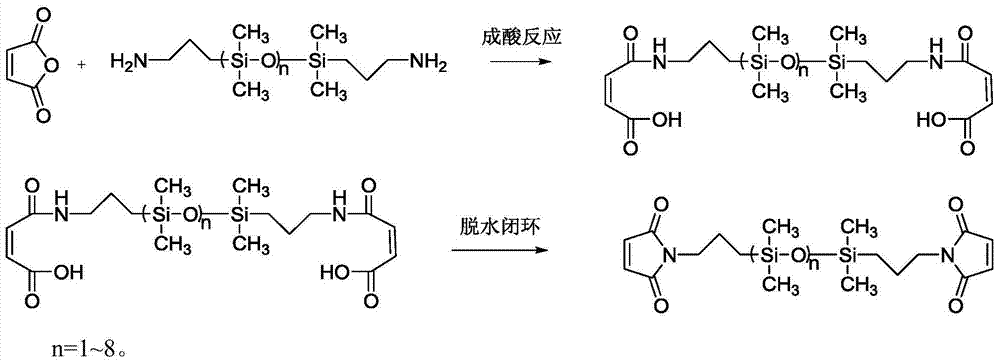

[0043]1. Take the epoxy resin, polyether-modified epoxy resin, bismaleimide-modified polysiloxane, furanyl group by weighing the weight percentage of each raw material in Table 1 accounting for the total weight of the raw material. Put glycidyl ether, coupling agent, and pigment into the reaction kettle, stir and mix;

[0044] 2. Weigh the spherical silicon micropowder, add it into the reaction kettle of step 1 at intervals in batches, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com