High-performance double-bond-containing epoxy resin/liquid rubber adhesive

A technology of epoxy resin and liquid rubber, which is applied in the direction of modified epoxy resin adhesives, rubber-derived adhesives, carboxyl rubber adhesives, etc., can solve the problems of sulfur rarely reported, and achieve the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is illustrated below in conjunction with specific examples, but is not limited to the following examples.

[0038] Mix 100 parts of epoxy resin containing double bonds, 0-100 parts of liquid rubber, 10-60 parts of epoxy resin curing agent, 3-20 parts of vulcanizing agent, and 0-8 parts of vulcanization accelerator. Mechanically stir evenly.

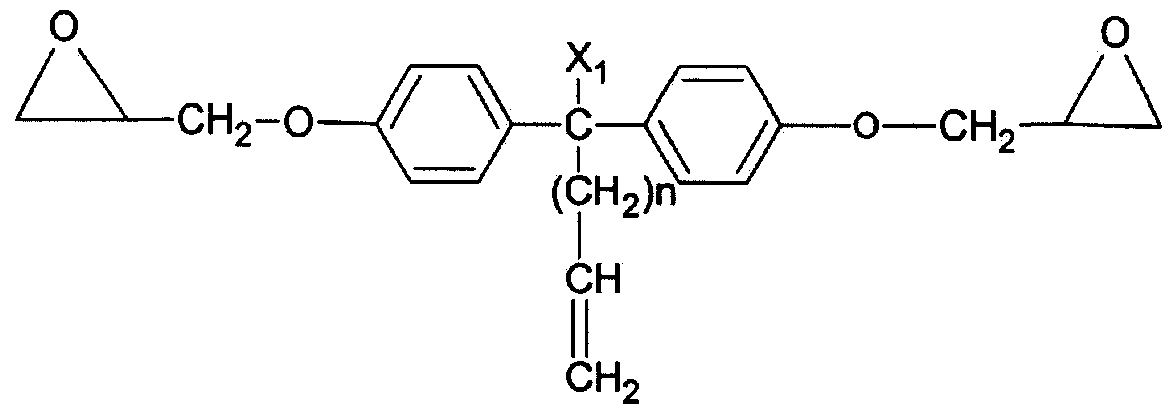

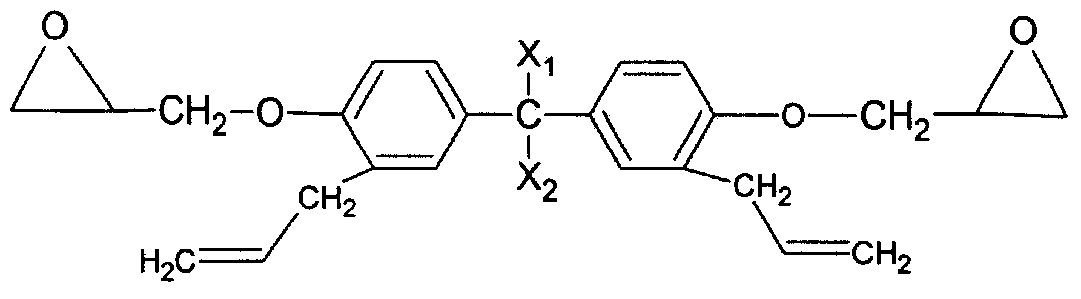

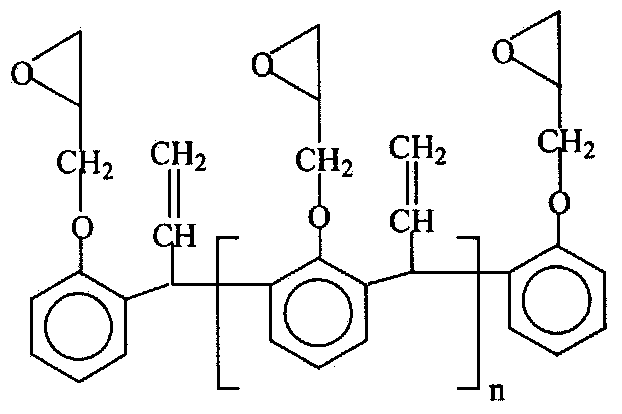

[0039] Embodiment 1-7 is the embodiment of diallyl bisphenol A epoxy resin (DADGEBA), liquid acrylonitrile-butadiene rubber (NBR) and curing system, and concrete implementation formula is listed in table 1.

[0040] All liquid rubbers and curing systems containing double bonds and epoxy rings, all unsaturated double bonds described above in the present invention can replace the diallyl bisphenol A epoxy resin (DADGEBA ), liquid nitrile rubber (NBR) and curing systems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com