High-performance silicon-based heat conduction mud and preparation method thereof

A heat-conducting mud and high-performance technology, which is applied in the field of high-performance silicon-based heat-conducting mud and its preparation, can solve the problems of high viscosity, high elongation at break, deformation, etc., and achieve moderate viscosity and elongation at break. The effect of high elongation and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

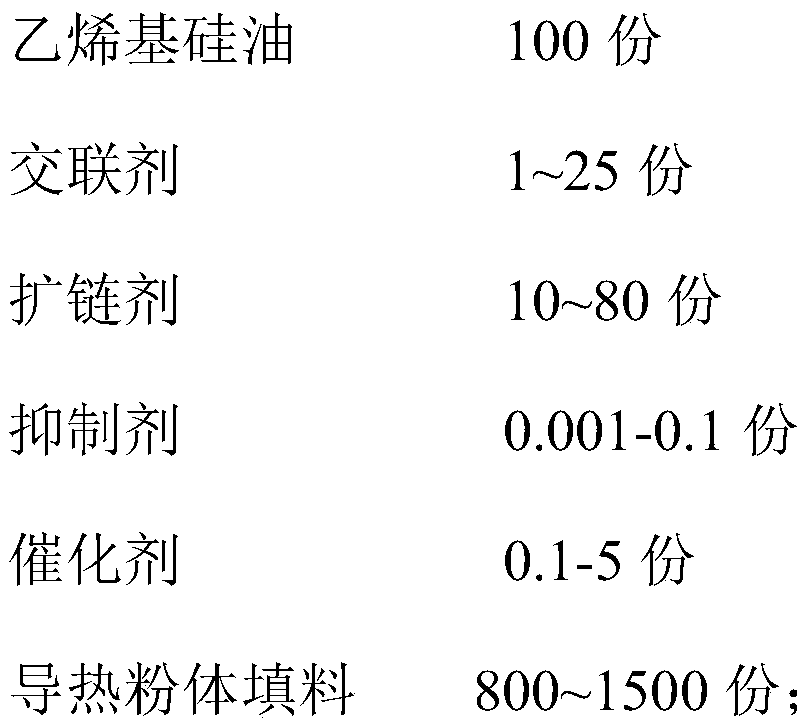

[0079] This embodiment provides a high-performance silicon-based heat-conducting putty, and its raw material composition is as follows:

[0080]

[0081] Note: 2 microns, 10 microns and 5 microns all refer to the particle size.

[0082] Concrete preparation method comprises the following steps:

[0083] a). Put 50 parts of single-ended vinyl silicone oil, 40 parts of double-ended vinyl silicone oil, and 10 parts of side vinyl silicone oil into the planetary machine, vacuumize to -500Pa, and stir for 10 minutes;

[0084] b). Put the mixed vinyl silicone oil into the kneader, then put in 7 parts of crosslinking agent, 30 parts of chain extender, and 0.1 part of inhibitor in turn, vacuumize to -500Pa, and stir for 20 minutes;

[0085] c). Turn on the kneader, put in 1400 parts of thermal conductive powder filler and 0.2 part of catalyst, evacuate to -500 Pa, stir for 30 minutes, and cool to obtain the high-performance silicon-based thermal conductive putty.

Embodiment 2

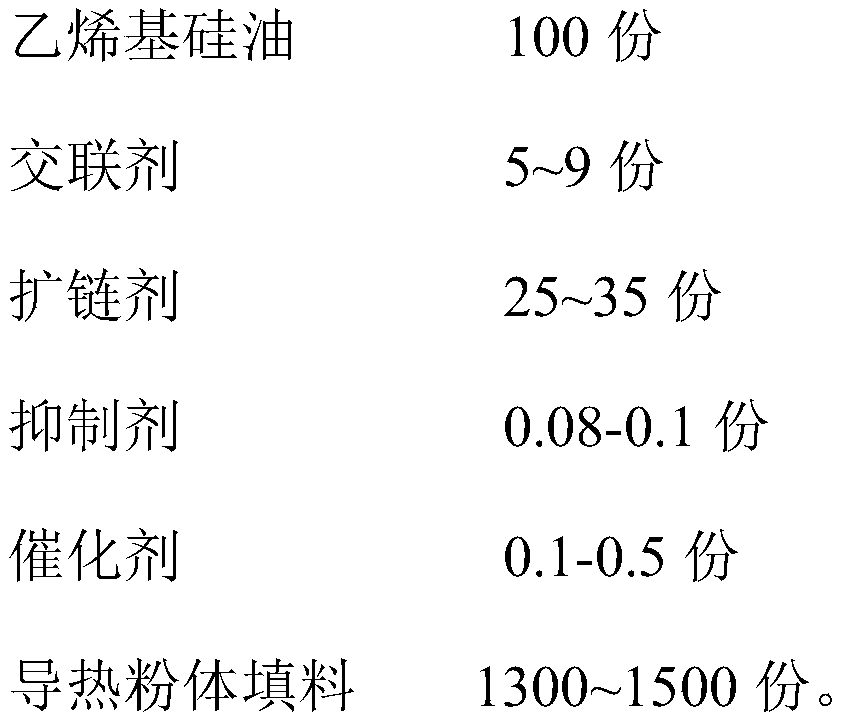

[0087] This embodiment provides a high-performance silicon-based heat-conducting putty, and its raw material composition is as follows:

[0088]

[0089] Concrete preparation method comprises the following steps:

[0090] a). Put 50 parts of single-ended vinyl silicone oil, 40 parts of double-ended vinyl silicone oil, and 10 parts of side vinyl silicone oil into the planetary machine, vacuumize to -500Pa, and stir for 10 minutes;

[0091] b). Put the mixed vinyl silicone oil into the kneader, then put in 1 part of crosslinking agent, 80 parts of chain extender, and 0.1 part of inhibitor in turn, vacuumize to -500Pa, and stir for 20 minutes;

[0092] c). Turn on the kneader, put in 800 parts of thermal conductive powder filler and 0.2 part of catalyst, evacuate to -500 Pa, stir for 30 minutes, and cool to obtain the high-performance silicon-based thermal conductive putty.

Embodiment 3

[0094] This embodiment provides a high-performance silicon-based heat-conducting putty, and its raw material composition is as follows:

[0095]

[0096] Concrete preparation method comprises the following steps:

[0097] a). Put 50 parts of single-ended vinyl silicone oil, 40 parts of double-ended vinyl silicone oil, and 10 parts of side vinyl silicone oil into the planetary machine, vacuumize to -500Pa, and stir for 10 minutes;

[0098] b). Put the mixed vinyl silicone oil into the kneader, then put in 25 parts of crosslinking agent, 10 parts of chain extender, and 0.1 part of inhibitor in turn, vacuumize to -500Pa, and stir for 20 minutes;

[0099] c). Turn on the kneader, put in 1500 parts of thermal conductive powder filler and 0.2 part of catalyst, evacuate to -500 Pa, stir for 30 minutes, and cool to obtain the high-performance silicon-based thermal conductive putty.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com