Ultra-low apparent density and high-performance foam concrete material and its preparation method

A foamed concrete and apparent density technology, applied in the field of building materials, can solve the problem of less foamed concrete with low apparent density, and achieve the effects of ultra-low apparent density, convenient operation and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

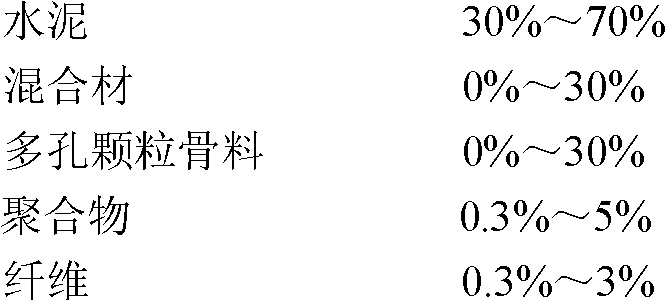

[0027]

[0028]

[0029] The total mass percentage of the above materials satisfies 100%.

[0030] Put 42.5 ordinary Portland cement, renewable rubber powder, and polypropylene fiber together into the container, and stir evenly to obtain a mixture of type A; mix polycarboxylate high-performance water reducer, hydroxymethyl cellulose ether with the above-mentioned measured water Add 1 / 3 of the water together in the mixer and stir to obtain the B mixture; Pour the commercially available animal glue surfactant (foaming agent) and the remaining 2 / 3 of the water into the foaming machine and stir to foam Type C mixture was obtained; then both mixtures B and C were added to type A mixture, stirred evenly and poured directly into the mold for molding. After molding, the mold was demoulded with natural curing for 3 days, and then cured for 14 days. Finally, the finished product is cut according to the requirements of use. Its apparent density is determined to be about 200kg / m 3...

Embodiment 2

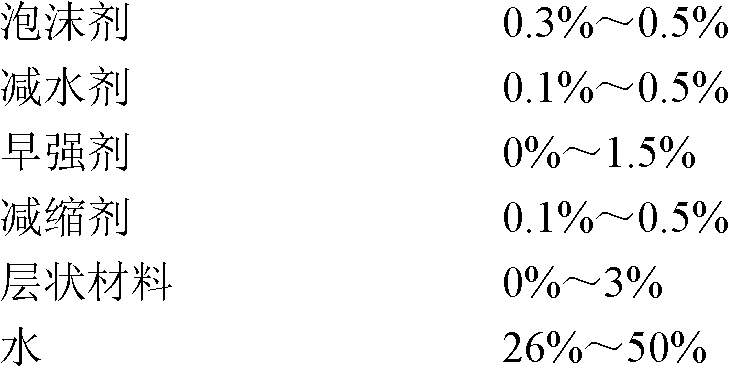

[0032] First measure according to the following mass percentages:

[0033]

[0034] The total mass percentage of the above materials satisfies 100%.

[0035] Put 42.5 Portland cement, mixed material S105 slag powder, polymer styrene-acrylic emulsion, and polypropylene fiber together into the container, and stir evenly to obtain a type A mixture; polycarboxylate water reducer, early strength agent CaCl2, shrinkage reduction The agent hydroxymethyl cellulose ether and 1 / 3 of water are added to another mixer and stirred evenly to obtain a mixture of type B; the animal glue surfactant and 2 / 3 of water are poured into a foaming machine and stirred and foamed to obtain a mixture of C Then add both mixtures B and C to the mixture A, stir evenly and pour it directly into the mold for molding: first pour 10mm thick into the mold, then add a layer of polyethylene film, and then pour 10mm thick, so cycle until the mould is filled, and it can be properly vibrated before adding polyeth...

Embodiment 3

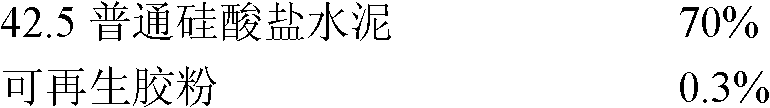

[0037] First measure according to the following mass percentages:

[0038]

[0039]

[0040] The total mass percentage of the above materials satisfies 100%.

[0041] Put 32.5 fly ash cement, vitrified microbeads (porous granular aggregate), renewable rubber powder (polymer), and cellulose fibers into the container together, stir evenly to obtain a mixture of type A; agent, triethanolamine (early strength agent), hydroxymethyl cellulose ether (shrinkage reducer) and 1 / 3 of water are added to another mixer and stirred evenly to obtain a mixture of type B; animal glue surfactant and 2 / 3 Pour the water into the foaming machine to stir and foam to obtain a mixture of type C; then add both mixtures B and C to the mixture of type A, stir well and pour it directly into the mold for molding: first pour about 10mm into the mold thick, and then add a layer of aluminum foil (layered film material), and then pour about 10mm thick, and so on until the mould is filled, and vibrate pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com