Fireproof coating for thick formed steel constructions

A fire-resistant coating and steel structure technology, applied in the field of fire-resistant coatings, can solve the problems of coating environmental protection performance, impact resistance, impermeability and waterproof performance, anti-mildew performance, etc. Effects of smoke toxicity, waterproof and anti-seepage improvement, and impact resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

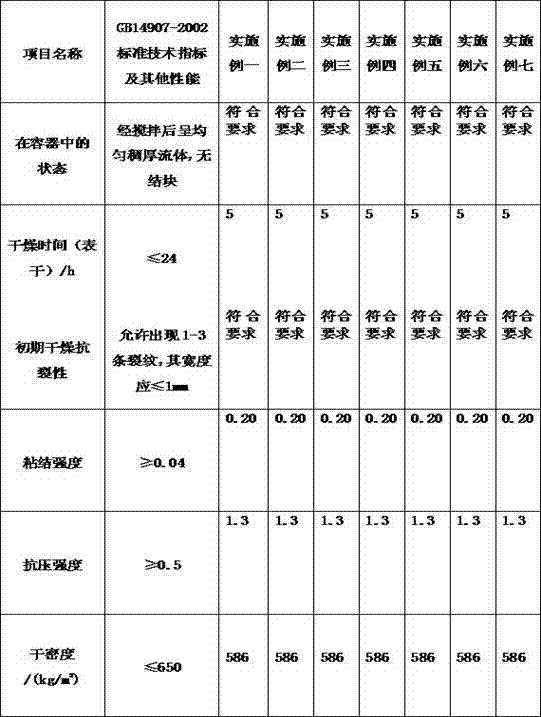

Examples

Embodiment 1

[0036] A fireproof coating for thick steel structures, the preparation method of which is as follows: first mix portland cement and high alumina cement in a ratio of 2:1 (by weight) to make the main adhesive, and then mix 36 parts Add the main binder, 5 parts of polyvinyl alcohol and 3 parts of glass fiber into the gravity-free mixer, turn on the flying knife to avoid sticking and prevent uneven mixing, the stirring time is 3 minutes, turn off the flying knife, and then add 5 parts of hydrogen Alumina, 5 parts of magnesium hydroxide, 5 parts of N-P composite flame retardant, 10 parts of wollastonite powder, 10 parts of mica powder, 0.25 parts of organic silane powder, 0.08 parts of antifungal agent ARGOS M6, continue stirring for 3 minutes , add 15 parts of expanded perlite; 15 parts of hollow glass microspheres, continue to stir, the stirring time is: 2 minutes, measure and pack the material. After the powder is stirred evenly, the ratio of powder to water is 1:0.78, and it i...

Embodiment 2

[0038] A fireproof coating for thick steel structures, the preparation method of which is as follows: add 36 parts of Portland cement, 5 parts of polyvinyl alcohol and 2.5 parts of glass fiber into a gravity-free mixer, and open the flying knife to avoid sticking and prevent stirring. Evenly, the stirring time is 3 minutes, close the flying knife, then add 15 parts of aluminum hydroxide, 8 parts of wollastonite powder, 12 parts of mica powder, 0.3 parts of organosilane powder, 0.1 part of antifungal agent ARGOS M6, continue stirring, stirring time For 3 minutes, add 16 parts of expanded perlite; 13 parts of hollow glass microspheres, and continue to stir. The stirring time is: 2 minutes, and the materials are measured and packaged. After the powder is stirred evenly, the ratio of powder to water is 1:0.8, and it is ready to use according to the weight ratio.

Embodiment 3

[0040] A fireproof coating for thick steel structures, the preparation method of which is as follows: Add 35 parts of high alumina cement, 4 parts of polyvinyl alcohol and 2 parts of glass fiber into a gravity-free mixer, and open the flying knife to avoid adhesion and prevent uneven mixing , the stirring time is 3 minutes, close the flying knife, then add 7 parts of aluminum hydroxide, 6 parts of magnesium hydroxide, 12 parts of wollastonite powder, 8 parts of mica powder, 0.25 parts of organic silane powder, 0.08 parts of antifungal agent ARGOS M6, Continue to stir, the stirring time is 3 minutes, add 18 parts of expanded perlite; 11 parts of hollow glass microspheres, continue to stir, the stirring time is 2 minutes, measure and pack the material. After the powder is stirred evenly, the ratio of powder to water is 1:0.78, and it is ready to use according to the weight ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com