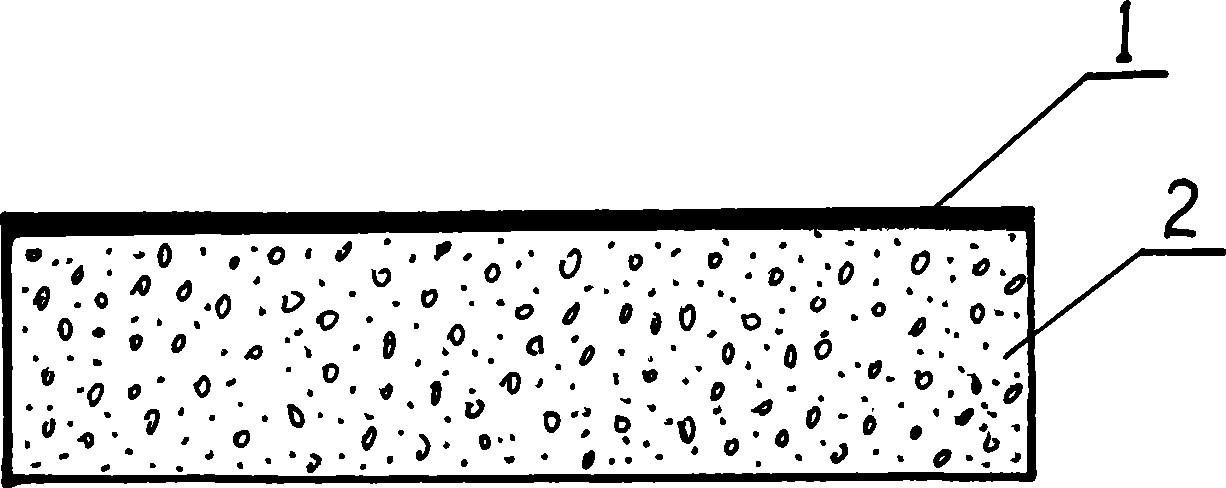

Inorganic heat-preserving metal facing one-piece type fire wall section material and its production method

An inorganic thermal insulation and firewall surface technology, applied in the field of building wall thermal insulation materials, can solve problems such as poor fire performance, unsafe operation, falling off, etc., achieve good thermal insulation performance, prolong service life, and eliminate expansion and contraction deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the present invention, the inorganic thermal insulation metal facing integrated fire wall surface profile can be carried out according to the following steps:

[0036] 1) First sieve from expanded perlite to select particles with a particle size of ≤3.5mm and ≥1.0mm, and add waterproofing agent and reinforcing agent according to the ratio of 75 parts of expanded perlite, 18 parts of waterproofing agent and 7 parts of reinforcing agent Mix evenly to make a modified hydrophobic expanded perlite particle core material; then take aluminum sulfate, aluminum phosphate, calcium stearate, aluminum stearate, and lignocellulose respectively, and grind and sieve them to make a particle size of 180~ After 230 mesh powders, according to the proportion by weight of 20 parts of aluminum sulfate, 30 parts of aluminum phosphate, 10 parts of calcium stearate, 10 parts of aluminum stearate, 5 parts of lignocellulose and 160 parts of water, mix and stir evenly to prepare Slurry, a part of...

Embodiment 2

[0042] The manufacturing method of the inorganic thermal insulation metal facing integrated wall profile of this embodiment is basically the same as that of Embodiment 1, the only difference being that the proportioning of each raw material when preparing the modified hydrophobic expanded perlite granular core material can be: 85 parts of expanded perlite, 22 parts of waterproofing agent and 9 parts of reinforcing agent; The weight percent of each raw material can be when preparing slurry: 30 parts of aluminum sulfate, 40 parts of aluminum phosphate, 15 parts of calcium stearate, 15 parts of aluminum stearate 10 parts, 10 parts of lignocellulose and 200 parts of water; the volume ratio of core material and slurry can be when preparing inorganic insulation lightweight aggregate: core material: slurry=1: 1.5; The volume ratio of the inorganic thermal insulation lightweight aggregate can be: slurry: inorganic thermal insulation lightweight aggregate = 1:4; the wet billet of the wa...

Embodiment 3

[0044] The preparation method of the fire wall profile with integrated inorganic thermal insulation metal finish is basically the same as that of Example 1, the only difference is that the ratio of each raw material when preparing the modified hydrophobic expanded perlite granular core material can also be : 80 parts of expanded perlite, 20 parts of waterproofing agent and 8 parts of reinforcing agent; The weight percent of each raw material can also be when preparing slurry: 25 parts of aluminum sulfate, 35 parts of aluminum phosphate, 12 parts of calcium stearate, stearic acid 12 parts of aluminum, 7 parts of lignocellulose and 180 parts of water; the volume ratio of the core material and the slurry can also be: core material: slurry = 1: 1.2 when preparing the inorganic thermal insulation lightweight aggregate; The volume ratio of the slurry to the inorganic thermal insulation lightweight aggregate can also be: slurry: inorganic thermal insulation lightweight aggregate = 1:3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com