Insulating paint used for overhead high voltage line and preparation method thereof

A technology for insulating coatings and high-voltage wires, applied to organic insulators, plastic/resin/wax insulators, coatings, etc., can solve problems such as pole collapse, low efficiency, and delays in the decision-making time of commanders, and achieve a strong foundation Material adhesion, broad application prospects, strong self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

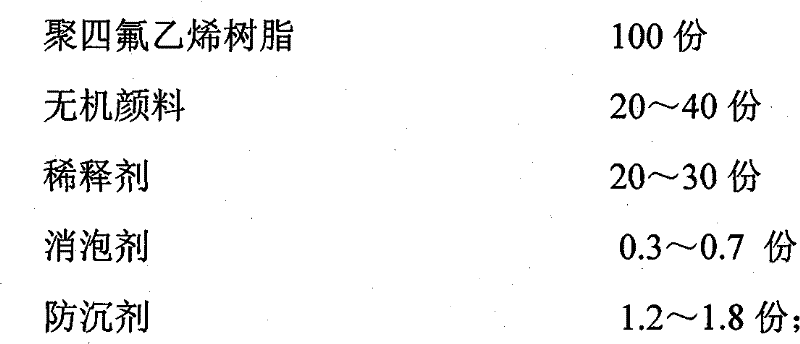

Embodiment 1

[0027] 100 parts of polytetrafluoroethylene resin (tetrafluoroethylene-ethylene copolymer, its hydroxyl value is 60mg / g resin, solid content is 60%), 20 parts of dry ground mica (1250 orders), 20 parts of butyl acetate, 6 parts of hexamethylene diisocyanate, 0.3 parts of silicone defoamer, 1.2 parts of organically modified bentonite as anti-settling agent. Preparation process: Add 20 parts of polytetrafluoroethylene resin, 20 parts of mica, 20 parts of butyl acetate, 0.3 parts of silicone defoamer, and 1.2 parts of anti-settling agent organically modified bentonite into a high-speed disperser, and rotate at 6000 rpm Disperse for 20 minutes at a speed of 1 / min, then adjust the speed to 500 rpm, add the remaining polytetrafluoroethylene resin in the formula, mix evenly, and filter to obtain the first component, and the curing agent hexamethylene diisocyanate as the second group Each part is packaged separately, when used, add it according to the above ratio, mix well and use it....

Embodiment 2

[0029] 100 parts of polytetrafluoroethylene resin (tetrafluoroethylene-ethylene copolymer, its hydroxyl value is 55 mg / g resin, solid content is 65%), 30 parts of dry ground mica (1500 orders), 25 parts of butyl acetate, 7 parts of hexamethylene diisocyanate, 0.3 parts of silicone defoamer, 1.5 parts of organically modified bentonite as anti-settling agent. Preparation process: 30 parts of polytetrafluoroethylene resin, 25 parts of butyl acetate, 0.3 parts of silicone defoamer, 1.5 parts of anti-sedimentation agent organically modified bentonite were added to the high-speed disperser, at a speed of 6000 rpm Disperse for 20 minutes, then adjust the speed to 500 rpm, add the remaining polytetrafluoroethylene resin in the formula, mix evenly, and filter to obtain component A. The curing agent hexamethylene diisocyanate is packaged separately as component B. When using, add it according to the above ratio, mix evenly and use it.

Embodiment 3

[0031] 100 parts of polytetrafluoroethylene resin (tetrafluoroethylene-ethylene copolymer, its hydroxyl value is 50 mg / g resin, and solid content is 70%), 40 parts of dry ground mica (2000 mesh), 30 parts of butyl acetate, 7 parts of hexamethylene diisocyanate, 0.5 parts of silicone defoamer, 2.0 parts of organically modified bentonite as anti-settling agent. Preparation process: 40 parts of polytetrafluoroethylene resin, 30 parts of butyl acetate, 0.5 parts of silicone defoamer, 2.0 parts of anti-sedimentation agent organically modified bentonite were added to the high-speed disperser, at a speed of 6000 rpm Disperse for 20 minutes, then adjust the speed to 500 rpm, add the remaining polytetrafluoroethylene resin in the formula, mix evenly, and filter to obtain component A. The curing agent hexamethylene diisocyanate is packaged separately as component B. When using, add it according to the above ratio, mix evenly and use it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com