Quick-curing super-weather-resistant low-gloss polyester resin for powder coating with flexibility and high hardness and preparation method thereof

A polyester resin, rapid curing technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of high brittleness, low gloss, sacrifice of weather resistance and surface hardness, etc., to overcome the brittleness problem and save energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

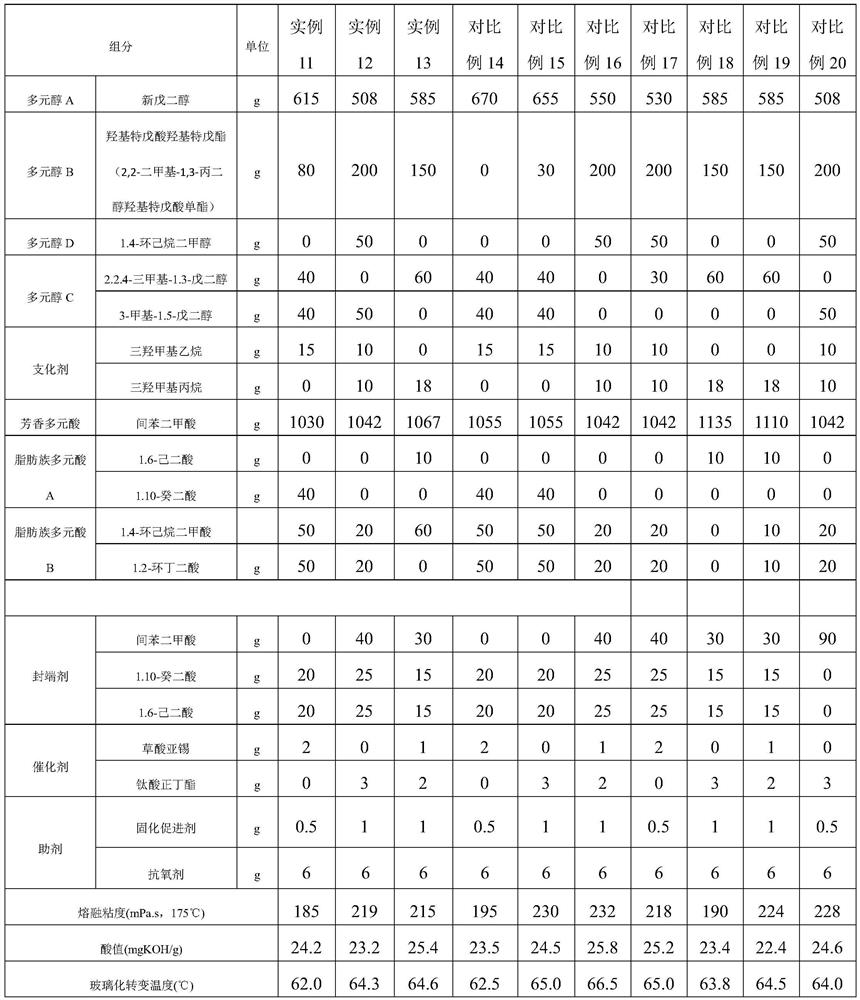

[0068] The present invention will be specifically introduced below in conjunction with specific embodiments.

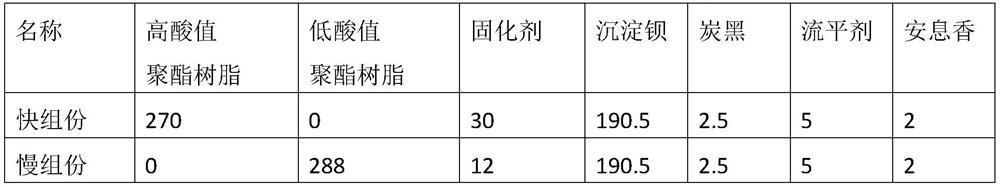

[0069] A group of fast-curing polyester resins for ultra-weather-resistant low-gloss powder coatings with both flexibility and high hardness, including: high acid value polyester resin and low acid value polyester resin;

[0070] High acid value polyester resin includes: aliphatic polyol A 15-40%, aliphatic polyol B 3-10%, aliphatic polyol C 2-5%, aliphatic polyol D 0-5%, Branching agent 0-3%, aliphatic polyacid A 5-15%, aliphatic polyacid B 0-5%, aromatic polyacid 40-60%, end-capping agent 4-8%, esterification catalyst 0.05- 0.15%, curing accelerator 2.5-1‰, antioxidant 3-5‰;

[0071] Aliphatic polyol A is neopentyl glycol; aliphatic polyol B is hydrogenated bisphenol A; aliphatic polyol C is 1.6-hexanediol, 1.4-butanediol, 3-methyl-1.5-pentanediol or a combination of one or more of 2-methyl-2-propyl-1.3-propanediol; the aliphatic polyol D is 1.4-cyclohexanedimetha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com