Production method of non-oriented silicon steel for extra-large generator and insulating coating of non-oriented silicon steel for extra-large generator

A technology of oriented silicon steel and production method, which is applied in the direction of coating, furnace type, device for coating liquid on the surface, etc., can solve problems such as unsatisfactory, and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

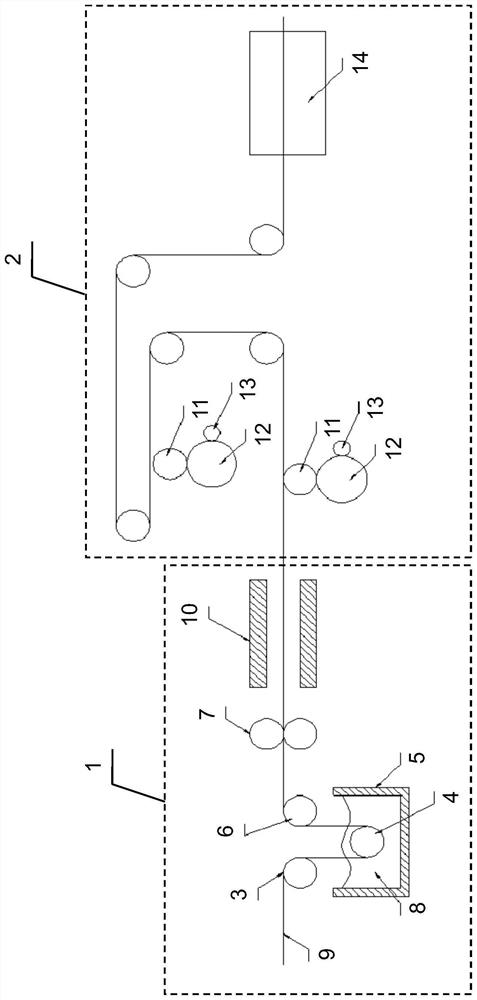

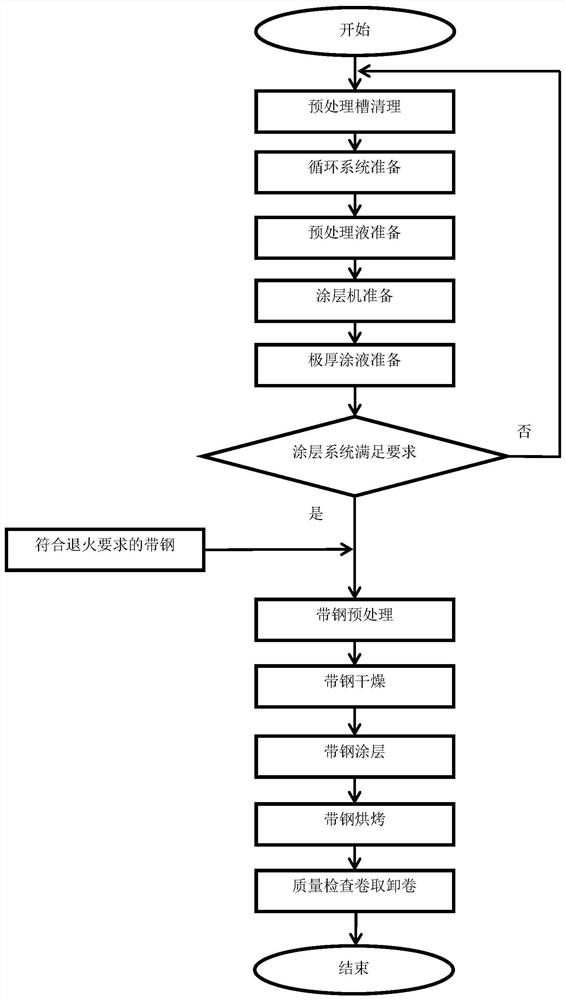

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] Please combine figure 1 with figure 2 As shown, a kind of non-oriented silicon steel production method that is used for extra-large generator provided by the present invention comprises strip steel cleaning process, and this strip steel cleaning process comprises decoiling process, cleaning process, drying process and high temperature annealing process, The foregoing is part of the prior art, and will not be repeated here. What is different from the prior art is that it also includes a strip cleaning promotion process 1 and a strip coating process 2 which are sequentially arranged at the back of the strip cleaning process.

[0044] Preferably, the strip cleaning promotion process 1 includes a secondary cleaning process and a secondary drying process. The secondary cleaning process includes an entrance turning roll 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com