High-hardness one-component transparent heat-insulation paint for glass

A heat-insulating coating, high hardness technology, applied in the direction of coating, etc., can solve the problems of paint film damage, paint film scratches, scratches, etc., and achieve the effects of avoiding damage, simple construction process, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

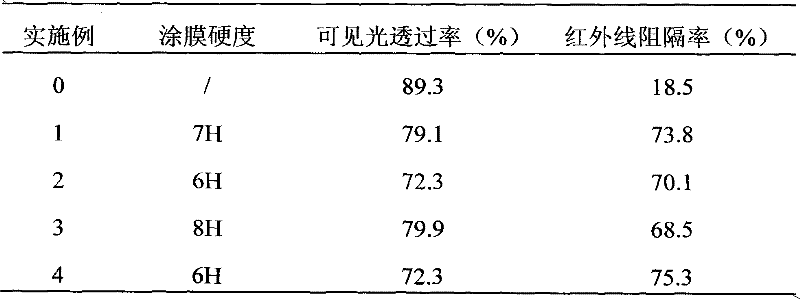

Examples

Embodiment 1

[0016] Add 60 parts of inorganic ceramic resin (A-10-9, Shanghai Ruiju Polymer Materials Co., Ltd.) and 40 parts of ATO slurry (China Shipbuilding Industry Corporation, solid content 21-22%) to the paint mixing tank in turn. , stir at 500rpm for 15min (min); slowly adjust the speed to 1500rpm (rev / min), gradually add 0.3 part of defoamer, continue stirring for 15min; add 0.15 part of foam inhibitor and 0.2 part of substrate wetting agent, reduce The rotating speed was adjusted to 800 rpm and stirred for 15 min; 6.5 parts of co-solvent diethylene glycol butyl ether was added, the rotation speed was adjusted to 600 rpm, and the stirring was continued for 20 min; the rotating speed was reduced to 500 rpm and defoaming was performed for 20 min. If there is still a lot of foam, it can be left to stand for about 24 hours to defoaming, then filtered and packaged.

Embodiment 2

[0018] Add 60 parts of inorganic ceramic resin (K7000, American Huajinsi Co., Ltd.) and 40 parts of ATO slurry into the paint mixing tank in turn, and stir at 600rpm for 15min; slowly adjust the rotation speed to 1000rpm, and gradually add 0.2 part of the Foaming agent, continue stirring for 15min; add 0.2 part of foam inhibitor and 0.3 part of substrate wetting agent, reduce the speed to 800rpm, add 0.3 part of leveling agent, continue stirring for 20min; reduce the speed to 500rpm, defoaming for 10min . If there is still a lot of foam, it can be left for about 12 hours to defoaming, then filtered and packaged.

Embodiment 3

[0020] Add 70 parts of inorganic ceramic resin (KZ-707, Philadelphia Chemical Company, USA) and 30 parts of ATO slurry (China Shipbuilding Industry Corporation, solid content 21-22%) in turn to the paint mixing tank, and stir at 600 rpm. 15min; slowly adjust the speed to 1000rpm, gradually add 0.3 part of defoamer, and continue stirring for 15min; add 0.2 part of foam inhibitor and 0.2 part of substrate wetting agent, reduce the speed to 800rpm, and stir for 15min; add 7.5 parts of auxiliary Solvent ethylene glycol butyl ether, adjust the rotation speed to 600rpm, continue stirring for 20min; lower the speed to 500rpm, defoaming for 20min. If there is still a lot of foam, it can be left for about 12 hours to defoaming, then filtered and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com