Separator for non-aqueous electrolyte battery and non-aqueous electrolyte battery

A non-aqueous electrolyte and separator technology, applied in non-aqueous electrolyte batteries, battery electrodes, secondary batteries, etc., can solve problems such as reducing the charge-discharge cycle characteristics, and achieve the effect of good cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 9~10

[0075] [Fabrication of Separator Formed from Laminated Microporous Membrane]

[0076] Polyamide having a structure shown below and having a melting point of 295° C. was used as the heat-resistant resin.

[0077] 【Chemical 4】

[0078] -[-R-(C=O)-NH-] n -

[0079] In the above structural formula, R represents a hydrocarbon group as shown below.

[0080] 【Chemical 5】

[0081] R=-CH 2 -CH 2 -C 6 h 4 -CH 2 - (bonding substituent at para position)

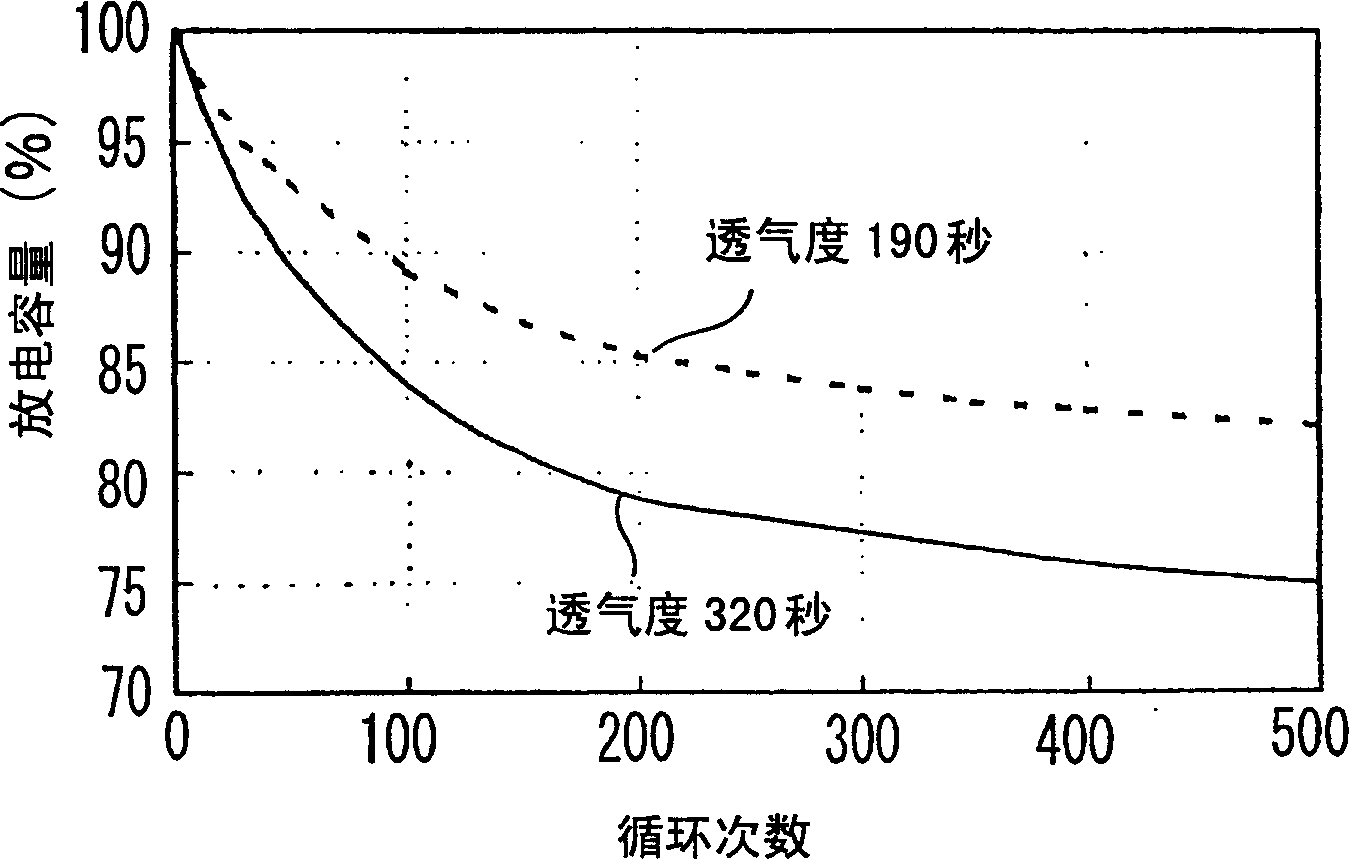

[0082] The above-mentioned polyamide was dissolved in an NMP solvent to a concentration of 1 mol / liter to prepare a heat-resistant resin solution. This resin solution was applied to a predetermined thickness on a polyethylene microporous membrane (thickness 4 μm, air permeability 190 seconds) used for the separator of Comparative Example 1 described later, and then immersed in water to release the resin solution into the water. The NMP in the resin coating film is removed, and the polyamide film is precipitated. A microporous...

Embodiment 4~6

[0085] A polyethylene microporous membrane with a thickness of 5 μm and an air permeability of 190 seconds was used in Example 4, a polyethylene microporous membrane with a thickness of 7 μm and an air permeability of 175 seconds was used in Example 6, and a thickness of 8 μm was used in Example 6. In addition, the polyethylene microporous membrane having an air permeability of 190 seconds formed a heat-resistant layer made of polyamide in the same manner as above. The thickness of the heat-resistant layer was 2 μm in Example 4, 3 μm in Example 5, and 2 μm in Example 6.

[0086]The air permeability of each obtained separator was measured, and the results are shown in Table 4. In addition, area shrinkage at 120°C, 130°C, 140°C, and 150°C was measured. The measurement results are shown in Table 4.

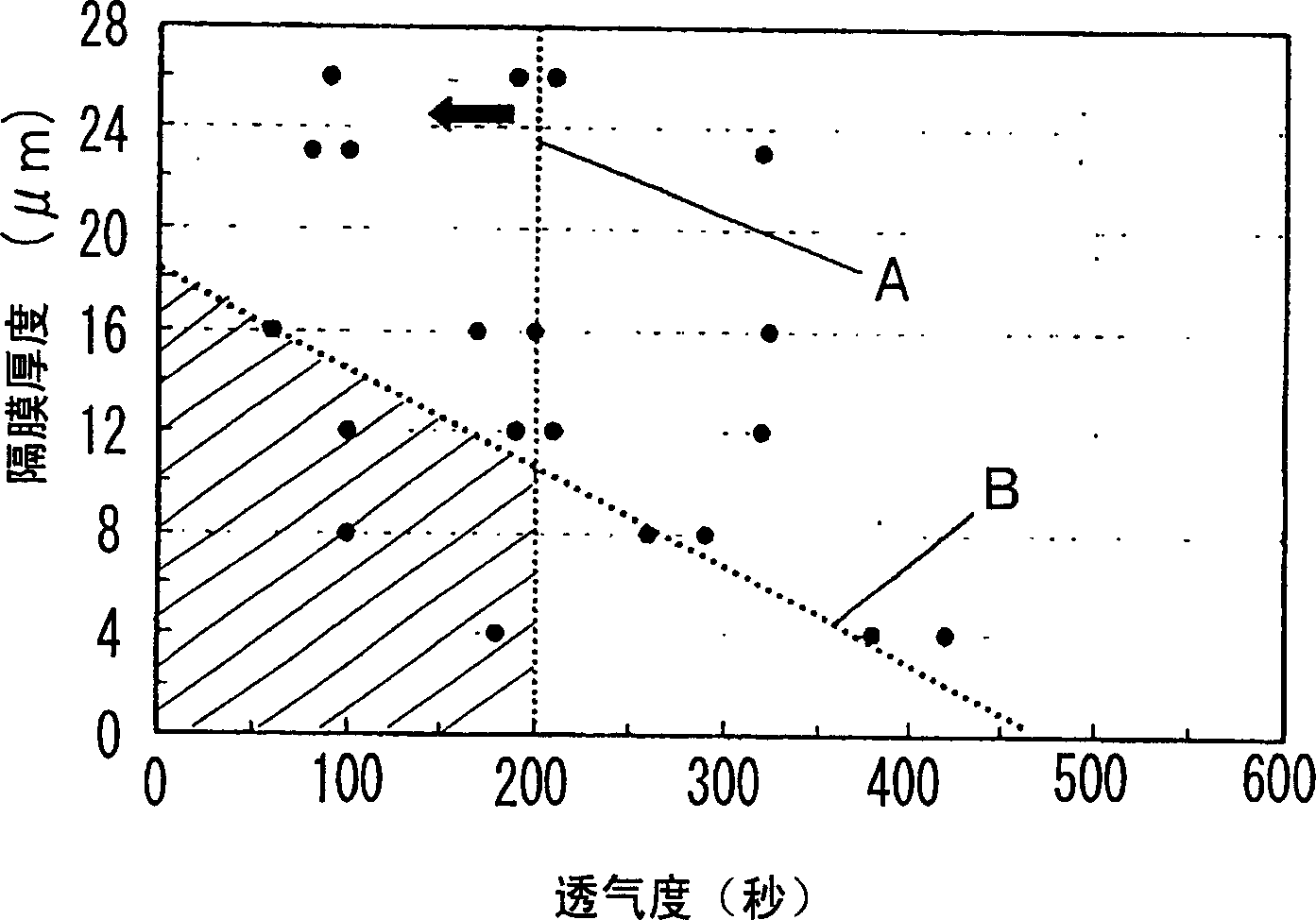

[0087] Here, the numbers in the column of film thickness in Examples 1 to 6 and Comparative Examples 9 to 10 are the film thickness of the polyethylene layer (polyolefin layer) and...

Embodiment 7

[0098] As the positive electrode active material, a lithium-transition metal composite oxide (lithium-nickel composite oxide) containing nickel, manganese, and cobalt shown in Table 5 as the transition metal was used instead of lithium-cobalt composite oxide (lithium cobaltate). Other than that, a lithium secondary battery was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com