Method for preparing corona-resistant enameled wire and product

A technology of corona resistance and enameled wire, which is used in cable/conductor manufacturing, circuits, insulated cables, etc., can solve the problems of limited corona resistance, poor adhesion and limited proportion, and achieve good adhesion and corona resistance. performance, the effect of meeting the requirements of corona resistance and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

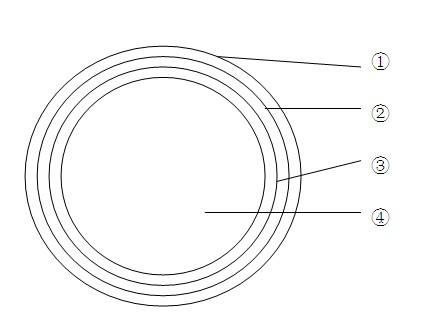

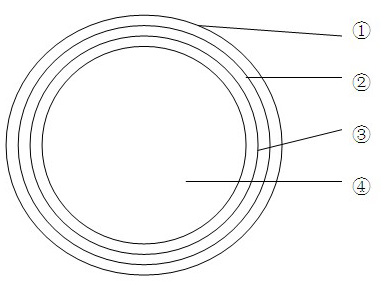

Image

Examples

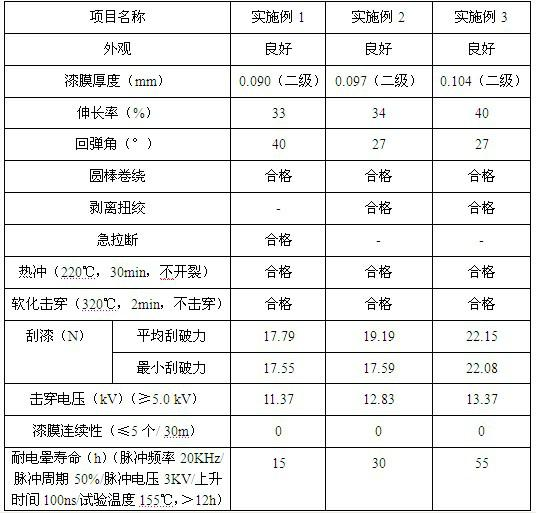

Embodiment 1

[0024] Description of materials and equipment used, (1) Polyester corona-resistant paint, self-made, viscosity (coated -4# cup, 30±1°C) 120s, solid content (2g / 200±2°C / 1h) 38%; (2 ) Polyesterimide corona-resistant paint, self-made, viscosity (coated with -4# cup, 30±1°C) 130s, solid content (2g / 200±2°C / 1h) 39%; (3) polyamideimide Paint, TONGMID 595 / 36MB, produced by Elantas, solid content (2g / 200±2℃ / 1h) 36%; (4) Enamelling machine, produced by Wuxi Tongchuang, vertical enameling machine, mold coating.

[0025] The preparation method is as follows:

[0026] (1) Wire drawing: First, anneal the Φ8.00mm low-oxygen copper rod on the large wire drawing equipment while annealing it into a Φ2.90mm semi-finished bare wire, and then pull it into the required specification bare copper wire on the intermediate drawing machine;

[0027] (2) Pay-off: place the qualified bare copper wire vertically below the ceramic ring of the pay-off frame, and use brush-type pay-off;

[0028] (3) Cl...

Embodiment 2

[0037] The preparation method of Example 2 is the same as that of Example 1, except that the copper core used is different, and the copper core wire of Ф1.25 mm is used; when making the insulating layer, the surface of the bare copper wire of Ф1.25 mm is coated with 4 coats of polyester corona-resistant paint, coated in sequence according to the paint molds of specifications 1.30, 1.31, 1.32, and 1.33, and then baked and cured one by one to form a polyester corona-resistant insulating layer; and then coated with 7 coats of polyesterimide Corona-resistant paint, coated in sequence according to the specifications of 1.33, 1.34, 1.35, 1.36, 1.37, 1.37, 1.38, and then baked and cured one by one to form a polyesterimide corona-resistant insulating layer; finally, two coats The polyamide-imide paint is applied sequentially according to the paint molds of 1.39 and 1.39 specifications, and is baked and cured one by one to form a polyamide-imide insulating layer, and finally a Ф1.25mm c...

Embodiment 3

[0039] The preparation method of Example 2 is the same as that of Example 1, except that the copper core used is different, and the copper core wire of Ф1.50 mm is used; when making the insulating layer, the surface of the bare copper wire of Ф1.50 mm is coated with 4 coats of polyester corona-resistant paint, coated in sequence according to the paint molds of specifications 1.55, 1.56, 1.57, and 1.58, and then baked and cured one by one to form a polyester corona-resistant insulating layer; and then coated with 7 coats of polyesterimide Corona-resistant paint, coated in sequence according to the paint molds of specifications 1.59, 1.60, 1.61, 1.62, 1.63, 1.64, 1.65, and then baked and cured one by one to form a polyesterimide corona-resistant insulating layer; finally coat 2 layers The polyamide-imide paint is applied sequentially according to the paint molds of 1.66 and 1.66 specifications. After baking and curing step by step, the polyamide-imide insulating layer is formed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com