Anti-static polytetrafluoroethylene filter bag and preparation method thereof

A polytetrafluoroethylene and filter bag technology, applied in the direction of filtration separation, separation method, dispersed particle filtration, etc., can solve problems such as poor anti-static, achieve the effect of eliminating static electricity, reducing fire or explosion accidents, and good electrical conductivity

Inactive Publication Date: 2013-07-10

南京际华三五二一环保科技有限公司

View PDF4 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the problem of poor anti-static in existing filter materials, the object of the present invention is to provide an anti-static polytetrafluoroethylene filter bag and its preparation method. The filter bag has high temperature resistance, corrosion resistance, good conductivity, and has Antistatic properties, suitable for combustible and explosive smoke and dust control in industrial kilns such as iron and steel smelting, waste incineration, coal-fired power plants, cement, chemical industry, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

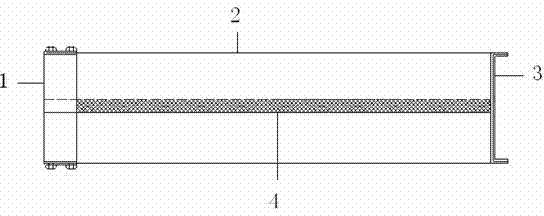

[0018] A preparation method for an antistatic polytetrafluoroethylene filter bag, comprising the following steps:

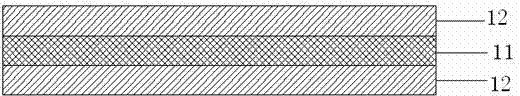

[0019] 1) The base fabric is obtained by twisting and plying polytetrafluoroethylene filament fibers and stainless steel fibers through warp and weft phase weaving;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an anti-static polytetrafluoroethylene filter bag and a preparation method thereof. The anti-static polytetrafluoroethylene filter bag comprises a bag head, a bag body and a bag bottom, wherein the bag head is made from a polytetrafluoroethylene filter material; the polytetrafluoroethylene filter material comprises a base cloth; the base cloth is weaved through warps and wefts by twisting polytetrafluoroethylene filament fibers and stainless steel fibers; the upper surface and lower surface of the base cloth are symmetrically covered with non-woven layers; the non-woven layers are prepared by blending polytetrafluoroethylene fibers or one or more of the polytetrafluoroethylene fibers, polyphenylene sulfide fibers, polyamide fibers, polyamide-imide fibers and glass fibers; and the overlapped edge of the bag body is provided with a stainless steel wire mesh layer. The filter material prepared through the method disclosed by the invention has the advantages of good high temperature resistance, corrosion resistance and electric conductivity and persistent static elimination, reduces the fire hazard or explosion generated due to electrostatic sparks and can be widely applied to the high-temperature fire prevention, explosion prevention and dust removal in the fields of iron and steel smelting, refuse burning, a coal-fired power plant, cement, chemical industry, and the like.

Description

technical field [0001] The invention belongs to the field of high temperature and corrosive flue gas purification, and relates to an antistatic polytetrafluoroethylene (PTFE) filter bag and a preparation method thereof. Background technique [0002] Chemical fiber filter materials used in steel smelting, waste incineration, coal-fired power plants, cement, chemical industry and other industrial kiln dust control do not have anti-static function, and the smoke generated in some process sections is flammable and explosive. During the process, due to the friction between dust and dust, dust and filter material, a large amount of static electricity is likely to be generated. If the charge cannot be eliminated in time, fire or explosion accidents will occur. Due to its excellent high temperature resistance and corrosion resistance, PTFE material has been widely used in the field of high temperature smoke control, but at the same time, because it is a non-polar polymer, it is easy...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D39/14B01D46/02B32B27/08B32B27/02B32B27/30B32B27/28

Inventor 阳建军刘建祥李敏徐新杰

Owner 南京际华三五二一环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com