Novel diamine compound, and preparation method and application thereof

An amine compound, a new type of technology, applied in the field of material science, can solve problems such as failure to achieve, and achieve the effects of easy purification, high yield, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

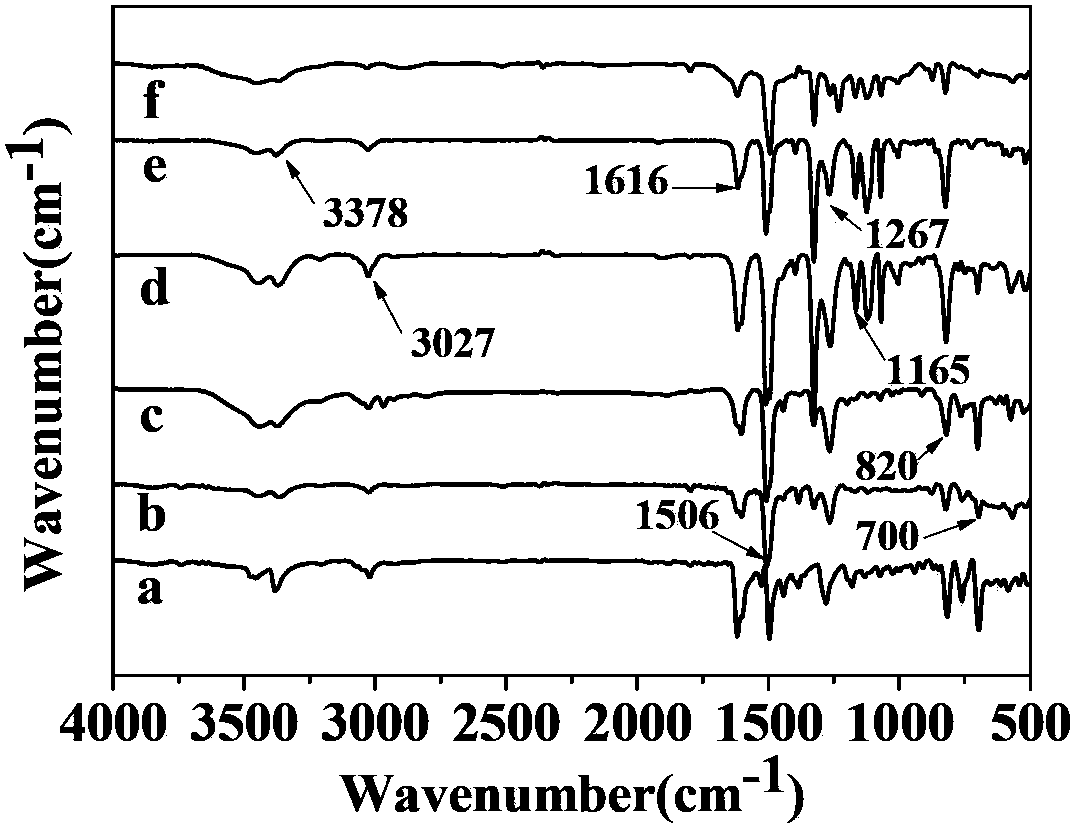

Method used

Image

Examples

Embodiment 1

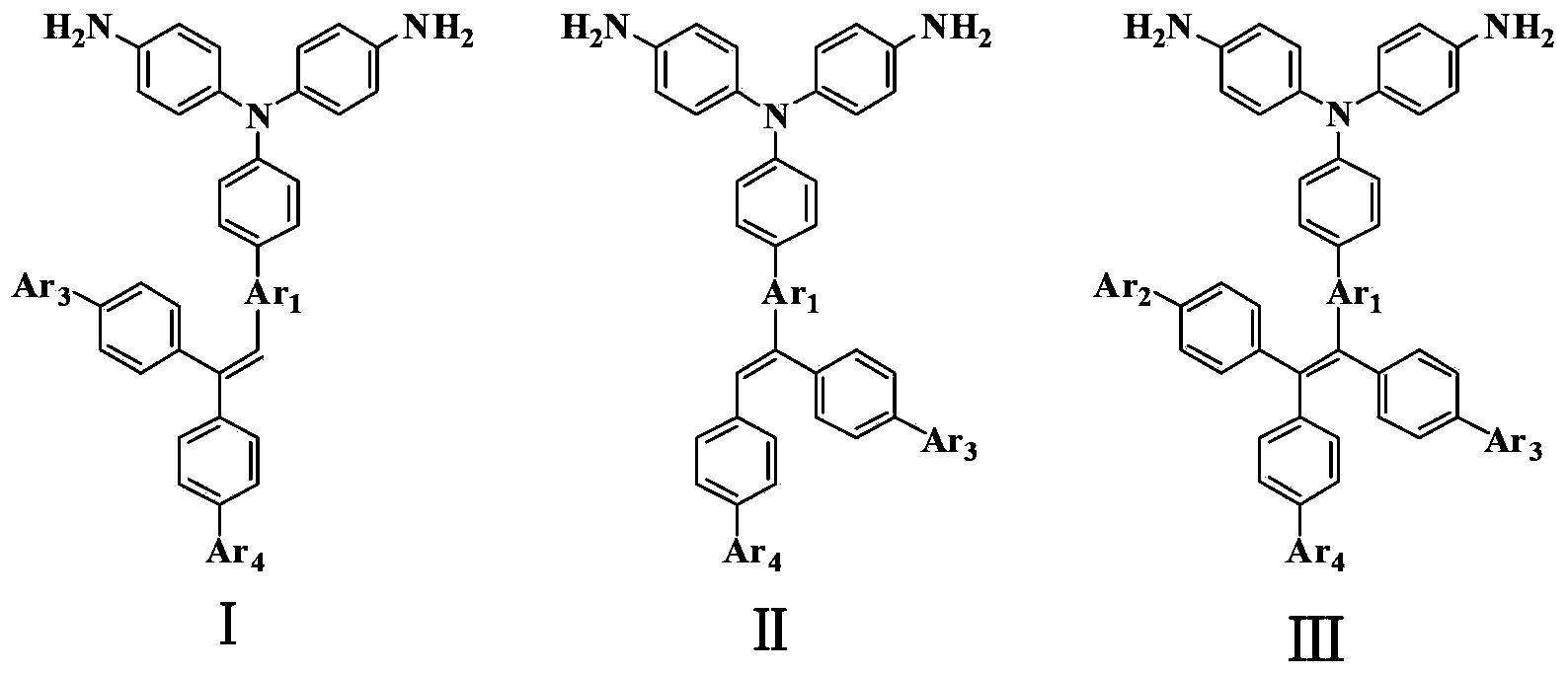

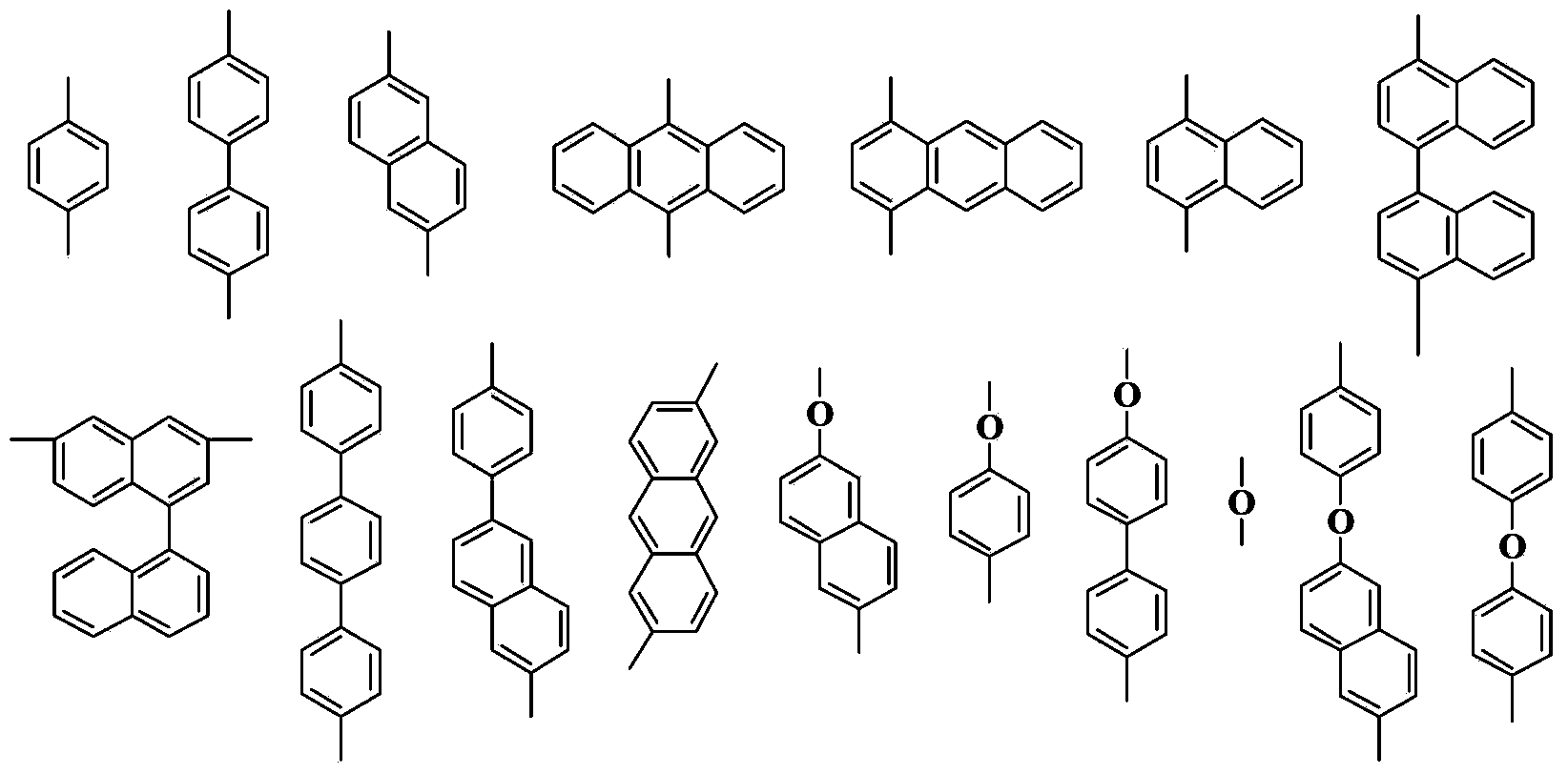

[0026] N1-(4-aminophenyl)-N1-(4'-(2,2-diphenylvinyl)biphenyl-4-yl)benzene-1,4-diamine (Tri-TPA-2NH 2 )Synthesis

[0027]

[0028] (1) Synthesis of intermediate 1-(2-(4-bromophenyl)-1-phenylvinyl)benzene.(Tri-Br):

[0029] Add 40.00 g of p-bromobenzyl bromide (0.16 mol) and 83.6 mL of triethyl phosphite (0.48 mol) into a 500 ml three-necked flask, stir magnetically and pass argon, heat and reflux in an oil bath at 150°C for 24 hours, then cool to room temperature, Obtain the ylide reagent. Add 450ml of tetrahydrofuran (THF) to the three-necked flask, then add 21.87g of benzophenone (0.12mol) and 40.39g of potassium tert-butoxide (t-BuOK, 0.36mol), stir magnetically for 24h, after the reaction stops, react The solution was poured into water for extraction, and a large amount of white precipitates precipitated out. The precipitates were collected by filtration with a funnel, washed with ethanol three times, and dried in vacuum at 60°C for 24 hours to obtain a white intermedi...

Embodiment 2

[0042] (E)-N1-(4-aminophenyl)-N1-(4'-(1,2-diphenylvinyl)biphenyl-4-yl)benzene-1,4-diamine(San-TPA-2NH 2 )

[0043]

[0044] (1) Synthetic intermediate (E)-1-bromo-4-(1,2-diphenylvinyl)benzene.(San-Br):

[0045] Add 6.33g (0.05mol) of benzyl chloride and 24.92g (0.15mol) of triethyl phosphite into a 500ml three-necked flask, magnetically stir and flow argon, heat and reflux in an oil bath at 150°C for 24h, cool to room temperature, and pour Add 300ml of tetrahydrofuran (THF) into the three-neck flask, then add 8.42g of potassium tert-butoxide (t-BuOK0.075mol) and 10.44g of 4-bromobenzophenone (bis(4-bromophenyl)methanone, 0.04mol), and stir magnetically for 24h. After the reaction stopped, the reaction solution was poured into water for extraction, and a large amount of white precipitates precipitated out. Filtered with a funnel, the precipitates were collected, washed with ethanol for 3 times, and dried in vacuum at 60°C for 24 hours to obtain a white intermediate product ...

Embodiment 3

[0056] N1-(4-aminophenyl)-N1-(4'-(1,2,2-triphenylvinyl)biphenyl-4-yl)benzene-1,4-diamine(SiPAP-2NH 2 ) together

[0057] (1) Synthesis of intermediate 1-bromo-4-(1,2,2-triphenylvinyl)benzene.(Si-Br):

[0058] Add 16.7mL (0.1mol) of diphenylmethane (diphenylmethane) and 300ml of tetrahydrofuran (THF) into a 500ml three-necked flask, magnetically stir and pass argon, and after 40min of ice-salt bath, add 54.5mL (0.12mol ) n-butyllithium solution, after continuing the ice-salt bath for 40min, add 13.0555g4-bromobenzophenone (bis(4-bromophenyl)methanone, 0.05), after reacting at room temperature for 12h, add 250ml saturated ammonium chloride ( NH 4 Cl) solution, after stirring for 10 minutes, pour the reaction solution into a separatory funnel, take its upper layer, and use 300g of anhydrous sodium sulfate to absorb the water in the solution, add it to a three-necked bottle after suction filtration, use 200ml of toluene as a solvent, and magnetically stir And pass argon, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com