Polyester resin for epoxy-cured powder coating with high glossiness and high leveling property and preparation method thereof

A technology of powder coating and polyester resin, applied in powder coating, epoxy resin coating, polyester coating, etc., can solve the problems of undiscovered patent reports, etc., and achieve the effect of excellent clarity, fullness and high leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

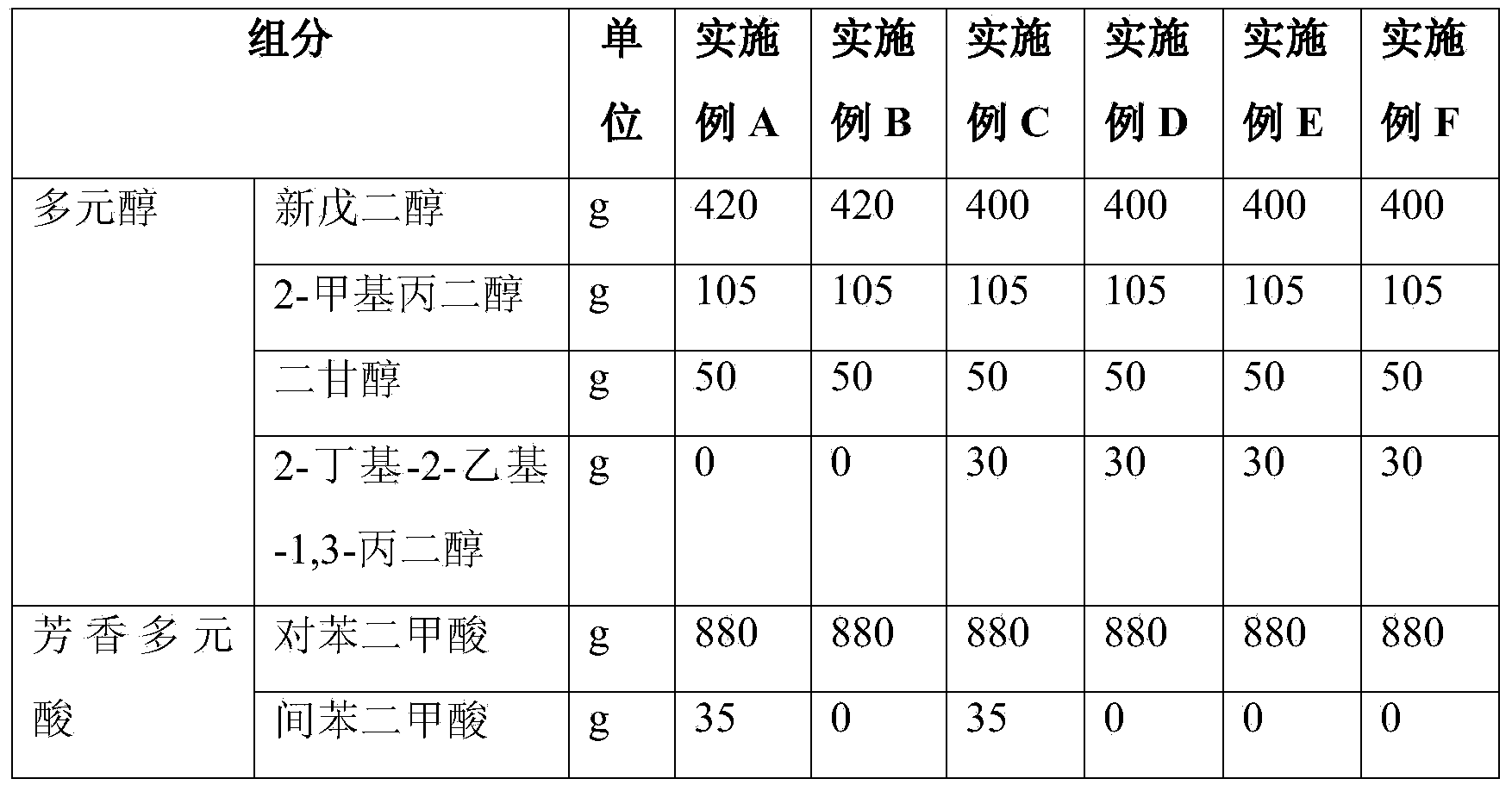

Examples

Embodiment Construction

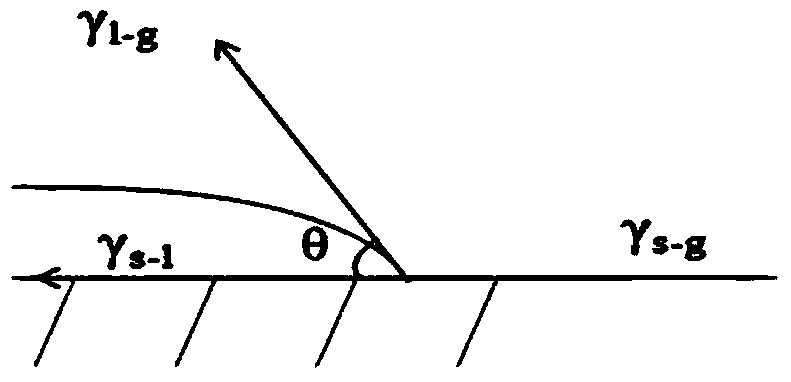

[0023] The surface condition of the paint film after the powder coating is cured depends largely on the surface tension and system viscosity during the melting and leveling process. Surface tension can be understood as: when two phases are in contact with each other, the transition zone with a thickness of several molecules at the junction is called the interface. If one of the phases is gas, this interface is usually called the surface. For the gas-liquid interface, the forces on the molecules inside the liquid can cancel each other out, but the surface molecules are strongly pulled by the bulk phase molecules, while the pull force by the gas phase molecules is small, and this microscopic force unevenness is amplified to the macroscopic phase interface , so that there is a kind of tension everywhere on the surface molecules. The force acting on the unit boundary line is called surface tension. The direction of the force points to the tangent direction of the interface, express...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com