A kind of perovskite single crystal flake and method and application for promoting its growth

A technology of perovskite and perovskite precursors, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of complex steps, poor crystal structure integrity and consistency, and poor controllability. To achieve a wide range of practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1, prepare 1.5mol / L MAPbBr at room temperature 3 , the solvent is DMF;

[0048] Step 2, prepare 4.2mol / L MAPbBr at 60°C 3 , the solvent is DMSO.

[0049] Step 3. Mix the solution prepared in step 1 and the solution prepared in step 2 in a volume ratio of 1:4, seal the mixed solution and place it on a hot table, heat and stir at 60°C, and obtain the precursor after mixing evenly. solution.

[0050] Step 4, Precursor Solution Filtration:

[0051] Filter the solution with a filter element with a pore size of 8 μm, and pipette 3 mL to 6 mL of the solution into a 30 mL polytetrafluoroethylene vial.

[0052] Step 5, fix the glass bottle containing the precursor solution and the teflon bottle in the oil bath, start heating from 60 °C, increase the temperature at a rate of 3 °C / h, and keep the temperature at 100 °C for observation. It was kept at 100°C for 8h.

[0053] Step 6, cleaning of single crystal:

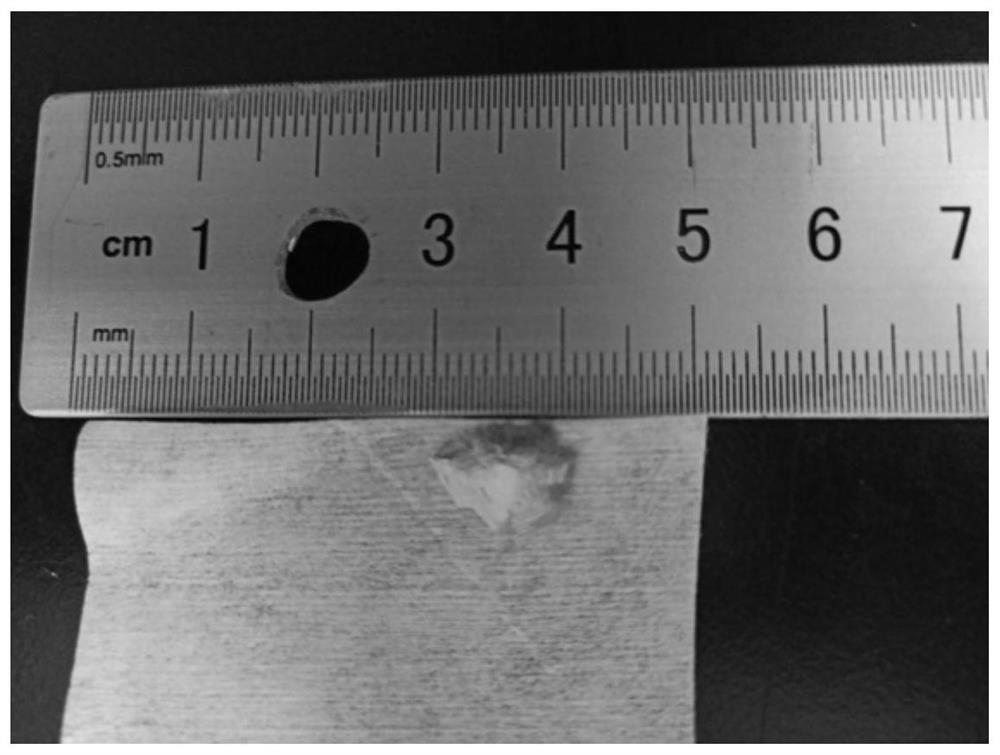

[0054] The grown MAPbBr 3 The perovskite single crystal is ...

Embodiment 2

[0057] Step 1, prepare 1.5mol / L MAPbI at room temperature 3 , the solvent is DMF;

[0058] Step 2, prepare 4.2mol / L MAPbI at 60°C 3 , the solvent is DMSO.

[0059] Step 3. Mix the solution prepared in step 1 and the solution prepared in step 2 in a volume ratio of 1:4, seal the mixed solution and place it on a hot table, heat and stir at 60°C, and obtain the precursor after mixing evenly. solution.

[0060] Step 4, Precursor Solution Filtration:

[0061] Filter the solution with a filter element with a pore size of 8 μm, and pipette 3 mL to 6 mL of the solution into a 30 mL polytetrafluoroethylene vial.

[0062] Step 5, fix the glass bottle containing the precursor solution and the teflon bottle in the oil bath, start heating from 60 °C, increase the temperature at a rate of 3 °C / h, and keep the temperature at 110 °C for observation. It was kept at 110°C for 6h.

[0063] Step 6, cleaning of single crystal:

[0064] The grown MAPbI 3 The perovskite single crystal is tak...

Embodiment 3

[0068] Step 1, prepare 1.5mol / L CsPbBr at room temperature 3 , the solvent is DMF;

[0069] Step 2, prepare 4.2mol / L of CsPbBr at 60°C 3 , the solvent is DMSO.

[0070] Step 3. Mix the solution prepared in step 1 and the solution prepared in step 2 in a volume ratio of 1:4, seal the mixed solution and place it on a hot table, heat and stir at 60°C, and obtain the precursor after mixing evenly. solution.

[0071] Step 4, Precursor Solution Filtration:

[0072] Filter the solution with a filter element with a pore size of 8 μm, and pipette 3 mL to 6 mL of the solution into a 30 mL polytetrafluoroethylene vial.

[0073] Step 5, fix the glass bottle containing the precursor solution and the teflon bottle in the oil bath, start heating from 60 °C, increase the temperature at a rate of 3 °C / h, and keep the temperature at 120 °C for observation. 120°C for 5h.

[0074] Step 6, cleaning of single crystal:

[0075] The grown CsPbBr 3 The perovskite single crystal is taken out fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

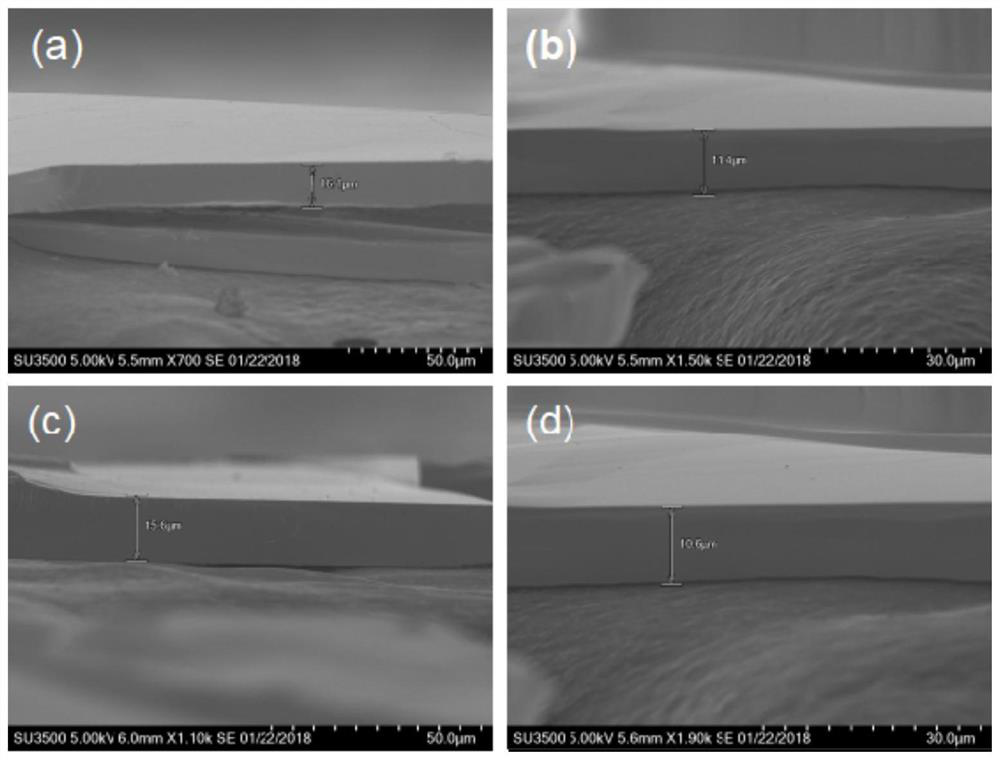

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com