Epoxy-modified water-based alkyd resin and water-based alkyd amino stoving varnish and preparation method of epoxy-modified water-based alkyd resin and water-based alkyd amino stoving varnish.

A water-based alkyd resin and epoxy modification technology, applied in coatings, polyester coatings, etc., can solve the problems of poor outdoor weather resistance, low water-based alkyd hardness, poor water resistance, etc., and achieve large formula adjustability , strong alkali resistance, solve the effect of low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

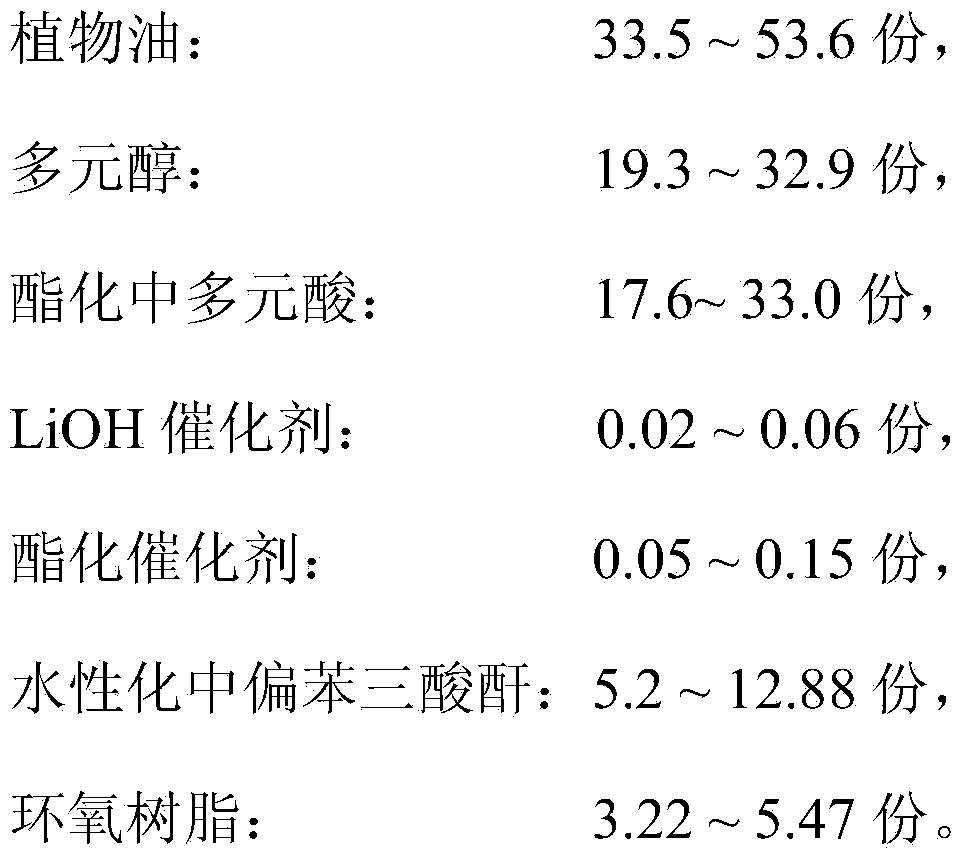

Method used

Image

Examples

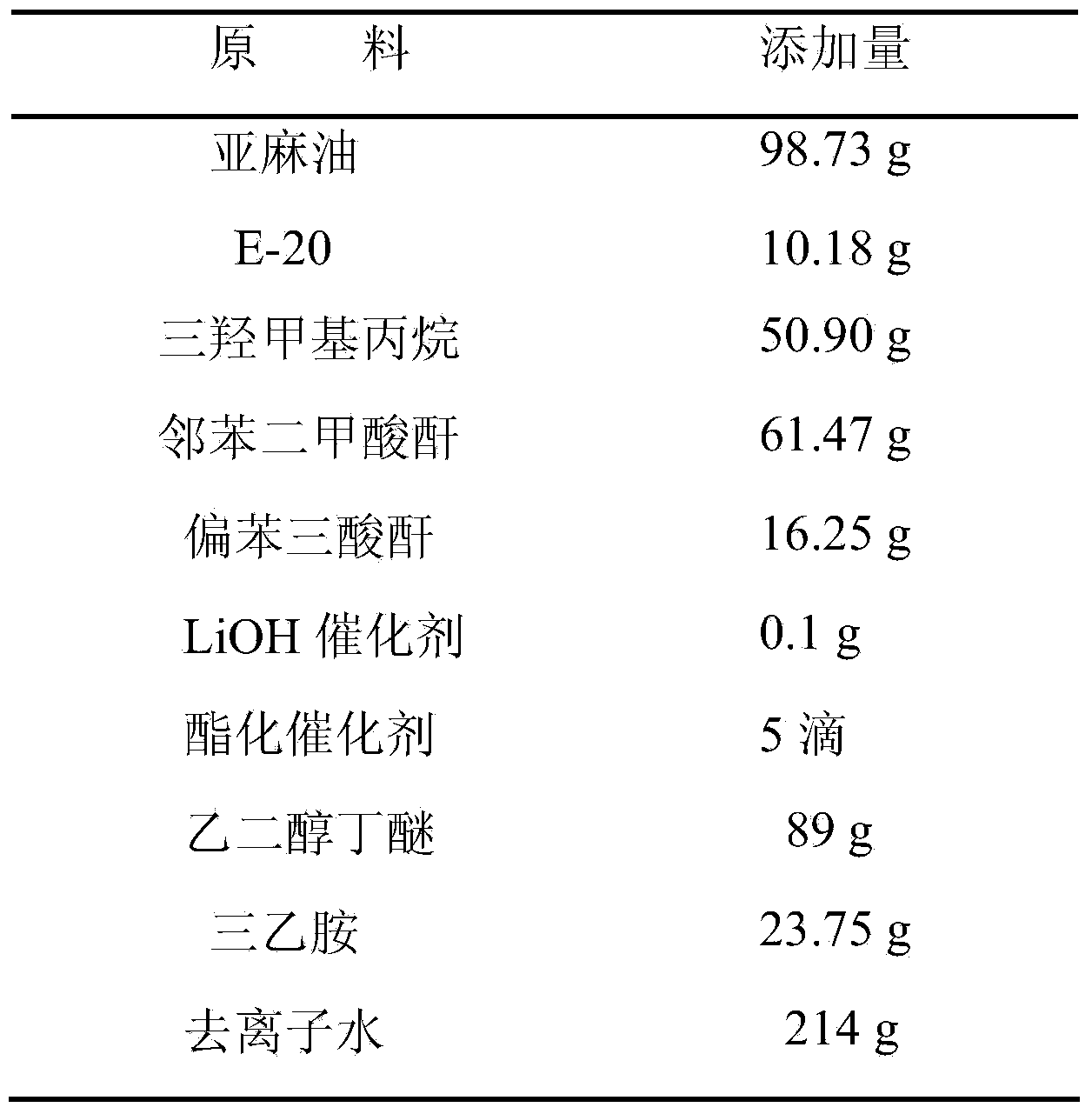

Embodiment 1

[0031] Add 98.73g of refined linseed oil, 10.18g of E-20, and 50.90g of trimethylolpropane into a straight-necked four-necked flask equipped with a stirring paddle, a thermometer, a condenser, and nitrogen gas, raise the temperature to about 120°C, and add 0.1g of LiOH catalyst, then slowly raise the temperature to 240°C and keep it warm for about 1 hour to obtain the alcoholysis product monoglyceride; when the product cools down to 160°C, add 61.47g of phthalic anhydride, start stirring, add 100g of xylene as a reflux solvent, At the same time, add 5 drops of esterification catalyst PC-9800, continue heating to 220-230°C and keep warm until the acid value is lower than 10mg KOH g -1 When it is qualified, stop heating, vacuumize to remove xylene, and feed N 2 , lower the temperature to 150-170°C, add 16.25g of trimellitic anhydride, raise the temperature to about 160°C, keep warm until the acid value is 40-60mg KOH·g -1 stop the reaction; cool the product to about 100°C, add ...

Embodiment 2

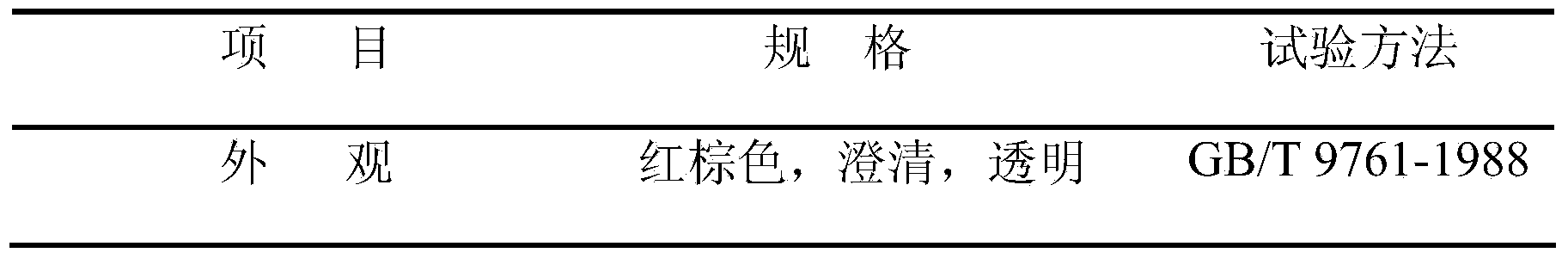

[0041] This implementation example adopts the same synthesis process as Example 1, only the epoxy resin in the raw material is replaced with E-44, and the amount of raw material is adjusted. The specific formula and specifications are shown in Tables 4, 5, and 6.

[0042] Table 4 Epoxy-modified water-based alkyd resin main formulation composition (component A)

[0043]

[0044] Table 5 Epoxy modified water-based alkyd resin technical indicators

[0045]

[0046] Table 6 Epoxy-modified water-based alkyd amino baking varnish formula

[0047]

[0048]

Embodiment 3

[0050] This implementation example adopts the same synthesis process as Example 2, only the amount of raw materials is changed, and the specific formula and specifications are shown in Tables 7, 8, and 9.

[0051] Table 7 Epoxy-modified water-based alkyd resin main formula composition (component A)

[0052]

[0053] Table 8 Epoxy modified water-based alkyd resin technical indicators

[0054]

[0055] Table 9 Epoxy-modified water-based alkyd amino baking varnish formula

[0056]

[0057] The epoxy-modified water-based alkyd amino baking varnish prepared by the above-mentioned method of the present invention adopts a standard detection method, and its performance detection results are shown in Table 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com