Water soluble alkyd resin solution and water-soluble alcohol acid amino baking varnish

A technology of alkyd resin and alkyd amino, applied in the field of paint, can solve the problems of poor gloss and distinctness of image, high curing temperature, and low curing temperature of the paint film, and achieve excellent appearance, distinctness of image and fullness Excellent, sharper and fuller effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A water-soluble alkyd resin solution, its weight percent composition is: castor oil 18.33%, benzoic acid 3.13%, phthalic anhydride 19.20%, trimellitic anhydride 6.16%, neopentyl glycol 4.29%, dimethylol propionic acid 3.94%, pentaerythritol 11.45%, propylene glycol methyl ether 10.08%, N,N-dimethylethanolamine 6.32% and water 17.10%;

[0020] The above-mentioned raw materials are prepared through the following steps: (1) Adding castor oil, benzoic acid, phthalic anhydride, trimellitic anhydride, neopentyl glycol, dimethylol propionic acid and pentaerythritol in the prescribed amount, and then raising the temperature for esterification; (2) raising the temperature to 160-175 ℃ for 1.0~1.5 hours without water separator reflux reaction; (3) add xylene, its addition is 3~6% of raw material total amount, be warming up to 175~180 ℃ of insulation reflux water diversion 1.5~2 hours; (4 ) to 190-195°C for reflux and water separation until the acid value is less than 65 mgKOH / g; ...

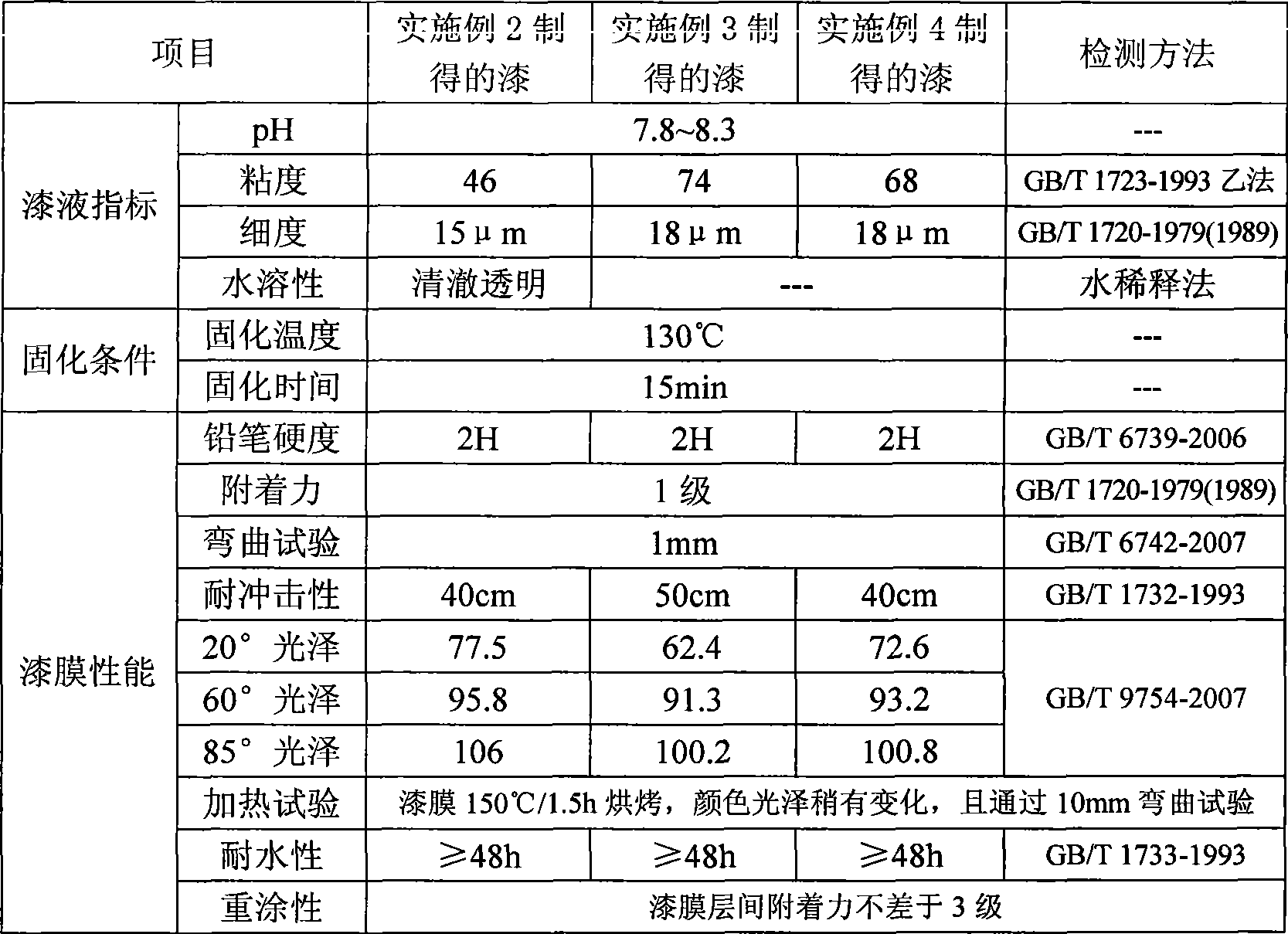

Embodiment 2

[0023] A water-soluble alkyd amino drying varnish varnish, which is composed of 65.93% water-soluble alkyd resin solution, 1.00% propylene glycol methyl ether, 17.14% CYMEL-303 amino resin, and 0.10% BYK-020 defoamer , BYK-307 leveling agent 0.05%, BYK-346 leveling agent 0.10% and water 15.68%;

[0024] The above-mentioned raw materials are mixed to obtain the varnish of the water-soluble alkyd amino drying paint.

Embodiment 3

[0026] A white varnish of water-soluble alkyd amino drying varnish, which is composed by weight percentage: 39.29% of water-soluble alkyd resin solution, 4.00% of propylene glycol methyl ether, 10.00% of CYMEL-303 amino resin, and 25.00% of pigment rutile titanium dioxide %, BYK-020 defoamer 0.10%, BYK-307 leveling agent 0.05%, BYK-190 dispersant 0.50%, BYK-346 leveling agent 0.10% and water 20.96%;

[0027] Grinding the water-soluble alkyd resin solution, pigments and additives to a fineness of ≤20 microns and then adding other raw materials in the formula to obtain the white gloss paint of the water-soluble alkyd amino drying paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com