Novel polyester enamelled wire paint and its preparation method

A polyester enameled wire varnish and a new technology, applied in the field of enameled wire varnish, can solve the problems of high cost, expensive solvent and the like of polyimide and polyamideimide, achieve good freezing resistance, simple preparation method and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

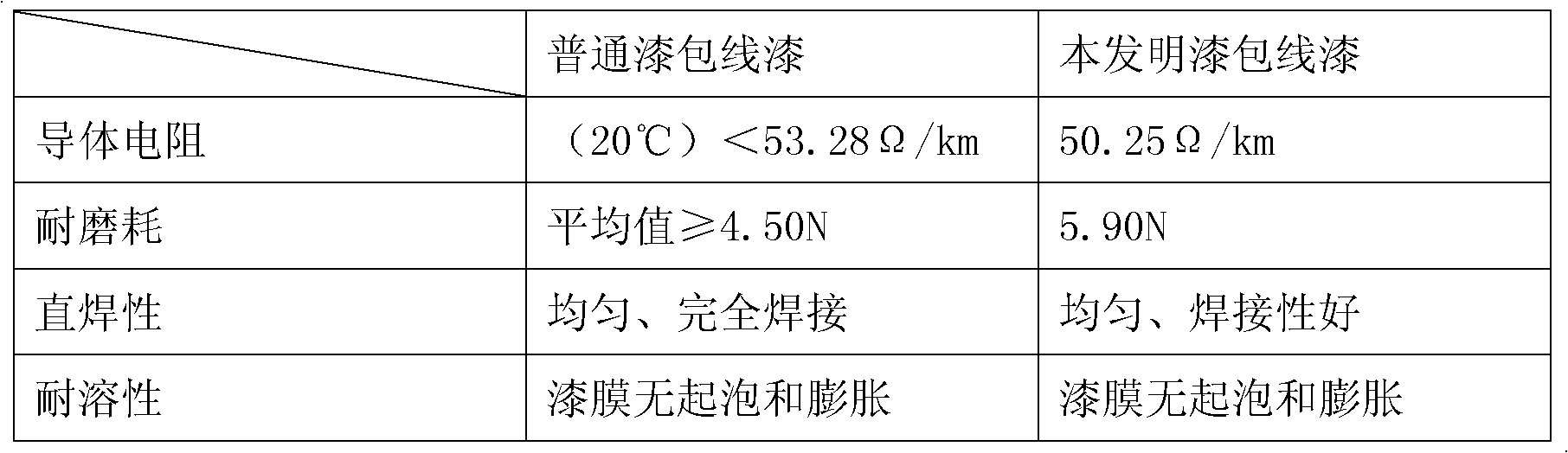

Examples

Embodiment 1

[0021] Embodiment 1: Novel polyester wire enamel, the parts by weight of its constituent raw materials are: 20 parts of rosin, 18 parts of maleic anhydride, 13 parts of dimethyl terephthalate, 15 parts of trimellitic anhydride, 3 parts of diaminodiphenylmethane, methane 13 parts of phenol, 13 parts of xylene, 8 parts of butyl orthotitanate, 15 parts of dibasic acid, 15 parts of aromatic diamine, 13 parts of diol, and 10 parts of triol.

Embodiment 2

[0022] Embodiment 2: Novel polyester wire enamel, the parts by weight of its constituent raw materials are: 25 parts of rosin, 20 parts of maleic anhydride, 15 parts of dimethyl terephthalate, 20 parts of trimellitic anhydride, 5 parts of diaminodiphenylmethane, methane 15 parts of phenol, 15 parts of xylene, 10 parts of butyl orthotitanate, 20 parts of dibasic acid, 20 parts of aromatic diamine, 15 parts of diol, and 12 parts of triol.

Embodiment 3

[0023] Embodiment 3: Novel polyester wire enamel, the parts by weight of its raw materials are: 30 parts of rosin, 25 parts of maleic anhydride, 18 parts of dimethyl terephthalate, 25 parts of trimellitic anhydride, 8 parts of diaminodiphenylmethane, methyl 18 parts of phenol, 18 parts of xylene, 12 parts of butyl orthotitanate, 25 parts of dibasic acid, 25 parts of aromatic diamine, 18 parts of diol, and 15 parts of triol.

[0024] The preparation method of novel polyester wire enamel of the present invention comprises the following steps:

[0025] (1) Add dimethyl terephthalate and trimellitic anhydride into the reactor according to the weight of the raw materials, heat to 150-200°C, and react for 4.5-5.5 hours;

[0026] (2) Add rosin, maleic anhydride, diaminodiphenylmethane butyl orthotitanate and aromatic diamine in parts by weight to the solution obtained in step (1), keep it at 155-180° C., and keep it warm for half an hour;

[0027] (3) Add dihydric alcohol, trihydric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com