Preparation method for polyamide imide coating

A polyamide-imide and coating technology, which is applied in the field of coating material preparation, can solve the problems of no obvious improvement in the surface properties of the coating, reduced mechanical properties of the coating, etc., and achieves short synthesis time, improved thermal properties, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

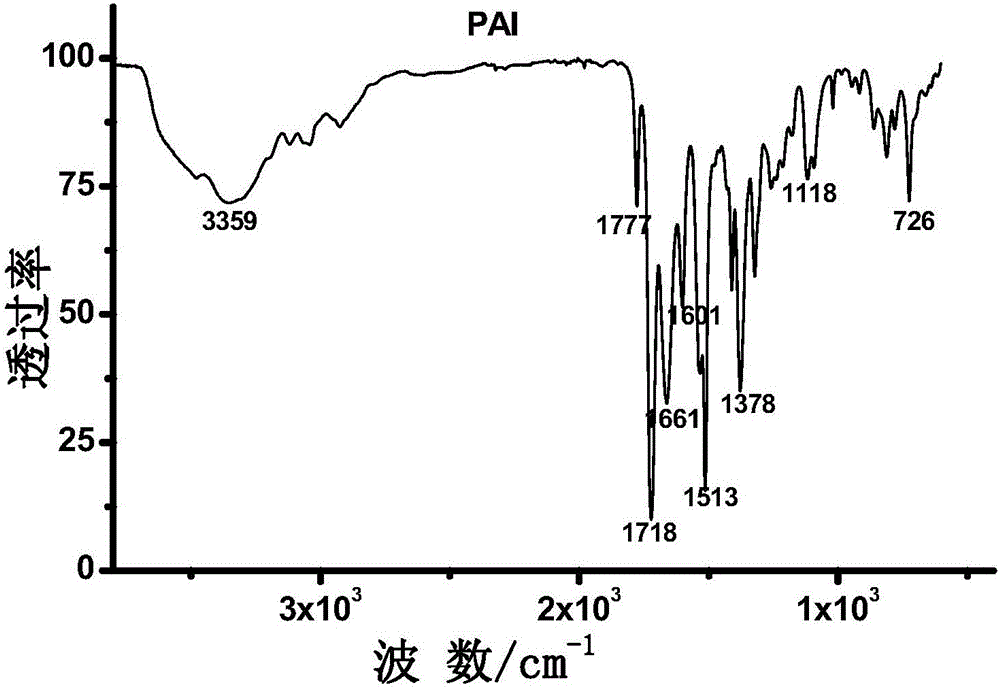

[0028] Add 0.01mol of pyromellitic anhydride and 0.09mol of trimellitic anhydride into the three-necked flask, then add 75ml of N-methylpyrrolidone and 10ml of xylene into the three-necked flask, heat to 80°C under nitrogen protection, stir for 30min, and wait for the pyromellitic After the acid anhydride and trimellitic anhydride are completely dissolved, add 0.1mol diphenylmethane diisocyanate, continue to stir at 80°C for 2.5h, then raise the temperature to 140°C, stir for 5h, then remove the three-necked flask and cool to room temperature. The obtained polymer solution was uniformly poured into deionized water containing 1% N-methylpyrrolidone, the polymer was precipitated, and the precipitated solution was replaced 5 times. Subsequently, the obtained tan solid was dried in a vacuum oven at 120°C for 24 hours to obtain a dried polymer. figure 1 It is the FTIR spectrum of the polymer, you can see 3353cm -1 It is N–H vibrational absorption peak, 1777cm -1 It is the extend...

Embodiment 2

[0033] Add 8mmol of pyromellitic anhydride and 0.092mol of trimellitic anhydride into the three-necked flask, then add 80ml of N-methylpyrrolidone and 15ml of xylene into the three-necked flask, heat to 80°C under nitrogen protection, stir for 30min, and wait for the pyromellitic anhydride to After completely dissolving with trimellitic anhydride, add 0.1mol diphenylmethane diisocyanate, continue to stir at 80°C for 3h, then raise the temperature to 140°C, stir for 5.5h, then remove the three-necked flask and cool to room temperature. The obtained polymer solution was uniformly poured into deionized water containing 1% N-methylpyrrolidone, the polymer was precipitated, and the precipitated solution was replaced 7 times. Subsequently, the obtained tan solid was dried in a vacuum oven at 120°C for 24 hours to obtain a dried polymer. 4 g of polyamide-imide was dissolved in 8 g of N-methylpyrrolidone treated with molecular sieves, and after complete dissolution, a polyamide-imide ...

Embodiment 3

[0037] Add 6mmol of pyromellitic anhydride and 0.094mol of trimellitic anhydride into the three-necked flask, then add 70ml of N-methylpyrrolidone and 15ml of xylene into the three-necked flask, heat to 80°C under nitrogen protection, stir for 30min, and wait for the pyromellitic anhydride to After completely dissolving with trimellitic anhydride, add 0.1mol diphenylmethane diisocyanate, continue to stir at 80°C for 3h, then raise the temperature to 140°C, stir for 6h, then remove the three-necked flask and cool to room temperature. The obtained polymer solution was uniformly poured into deionized water containing 1% N-methylpyrrolidone, the polymer was precipitated, and the precipitated liquid was replaced. Subsequently, the obtained tan solid was dried in a vacuum oven at 120°C for 24 hours to obtain a dried polymer. 4 g of polyamide-imide was dissolved in 4 g of N-methylpyrrolidone treated with molecular sieves, and after complete dissolution, a polyamide-imide coating with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com