Asbestos-free calcium silicate board and method for making same

A calcium silicate board, asbestos-free technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as unsupported, easy to break, and gypsum board is easy to break, and achieve strong resistance to subsidence performance, strong fire resistance and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

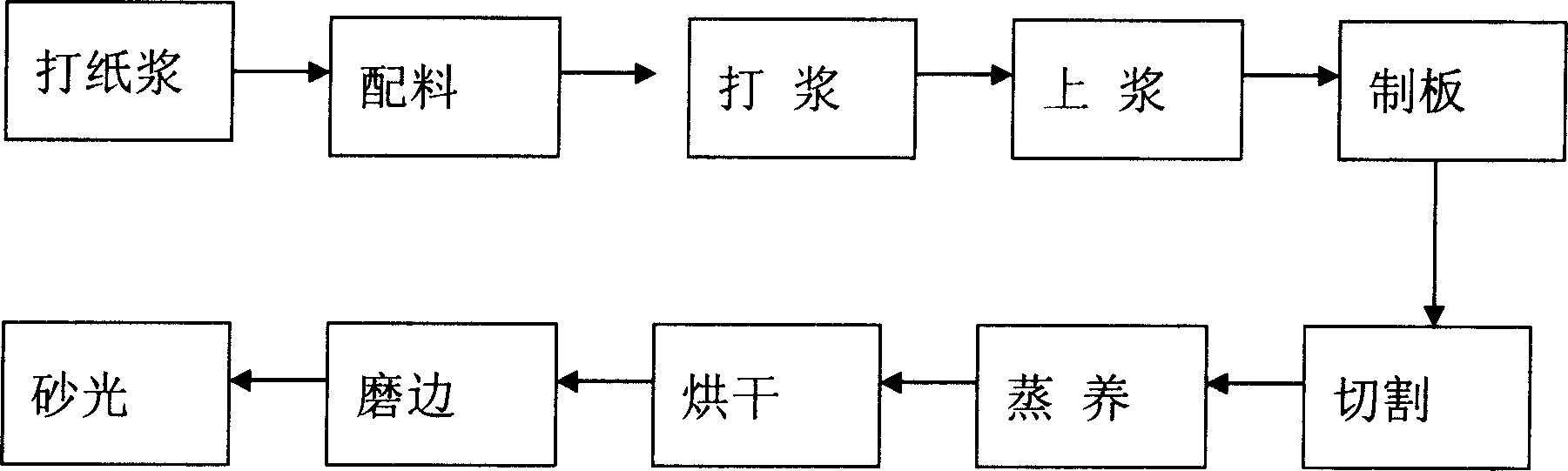

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: get respectively 48% of quartz sand, 18% of cement, 18% of lime, 3% of wollastonite acicular powder, 5% of mica powder, 8% of wood fiber, and 1‰ of polyacetamide; The fibers are made into shredded pulp without impurities, and then cement, quartz sand, lime, mica powder, wollastonite needle powder, and polyacetamide are evenly dosed in proportion with a batching machine, and the ingredients are beaten again by a beater, and then sizing is done through a flow machine , plate-making machine-made plate, cutting machine to cut the plate, after flattening the plate surface, steam curing for 18 hours under the constant pressure of 1.0Mpa in the autoclave, so that it is basically fully crystallized into tobermolite; Dry in a dry kiln to remove excess water, and finally grind the edge with a chamfering machine, and then sand it with a sander to form a calcium silicate board. The properties of the plate materials are shown in Table 1.

Embodiment 2

[0011] Embodiment 2: get respectively 38% of quartz sand, 24% of cement, 24% of lime, 8% of wollastonite acicular powder, 1% of mica powder, 5.5% of wood fiber, and 0.5‰ of polyacetamide; according to the steps of embodiment 1 Made of calcium silicate board. The properties of the plate materials are shown in Table 1.

Embodiment 3

[0012] Embodiment 3: Take 44.94% of quartz sand, 22.47% of cement, 22.47% of lime, 8.98% of wollastonite acicular powder, 1.14% of mica powder, 7% of wood fiber, and 1‰ of polyacetamide. The step of embodiment 1 makes calcium silicate board. The properties of the plate materials are shown in Table 1.

[0013] This product has been tested many times and its main technical indicators: Density 1.08g / cm 3 , The flexural strength is 16.4Mpa, the thermal conductivity is 0.108w / m.k, the moisture content is 8.0%, and the wet expansion rate is 0.16%. All meet the standards of the National Building Materials Testing Center. Use a multi-purpose knife, electrician's knife or carbonized sharp knife to draw a straight line on the calcium silicate board to a depth of about 1 / 3 of the thickness of the board. A straight saw or a circular saw can also be used for cutting; ordinary iron nails or screws can easily fix the asbestos-free calcium silicate board, and it is not easy to pull out.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com