Aluminum sectional material framework for old wall heat insulation structure modification

A technology of structural transformation and aluminum profiles, applied in thermal insulation, building components, etc., can solve the problems of long construction period and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

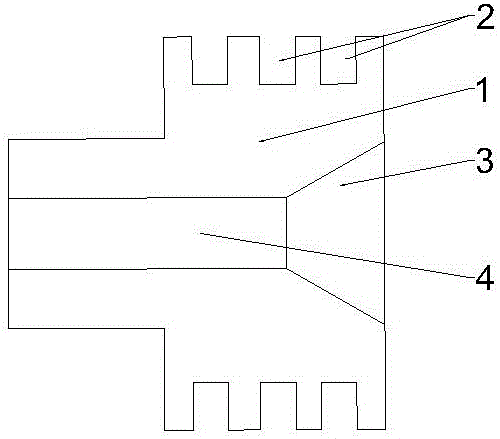

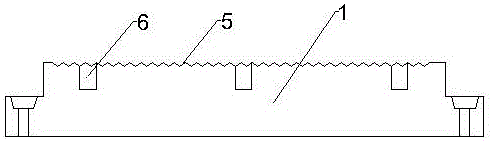

[0010] The present invention will be further explained below in conjunction with all the drawings. The preferred embodiment of the present invention is: see attached figure 1 And figure 2 In this embodiment, an aluminum profile frame for the transformation of an old wall insulation structure includes a main body 1. The cross section of the main body 1 is stepped, and the side with the smaller stepped surface is close to the wall. The length direction of the main body 1 A number of embedding grooves 2 are provided on the side walls on both sides. The embedding grooves 2 are distributed on the side walls of the main body 1 along the length direction. There are three embedding grooves 2 on each side of the main body 1; There is a conical counterbore 3, the bottom of the counterbore 3 is provided with a fixing hole 4, the main body 1 is fixed on the wall through the fixing hole 4 and expansion bolts; the surface of the main body 1 is provided with a concave-convex corrugated bondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com