Steel slag high-temperate modification method

A high-temperature modification and steel slag technology, which is applied in cement production and other directions, can solve the problems of not realizing the activity of steel slag, achieve the effect of improving volume stability and gelling activity, reducing content, and increasing the content of active mineral silicate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

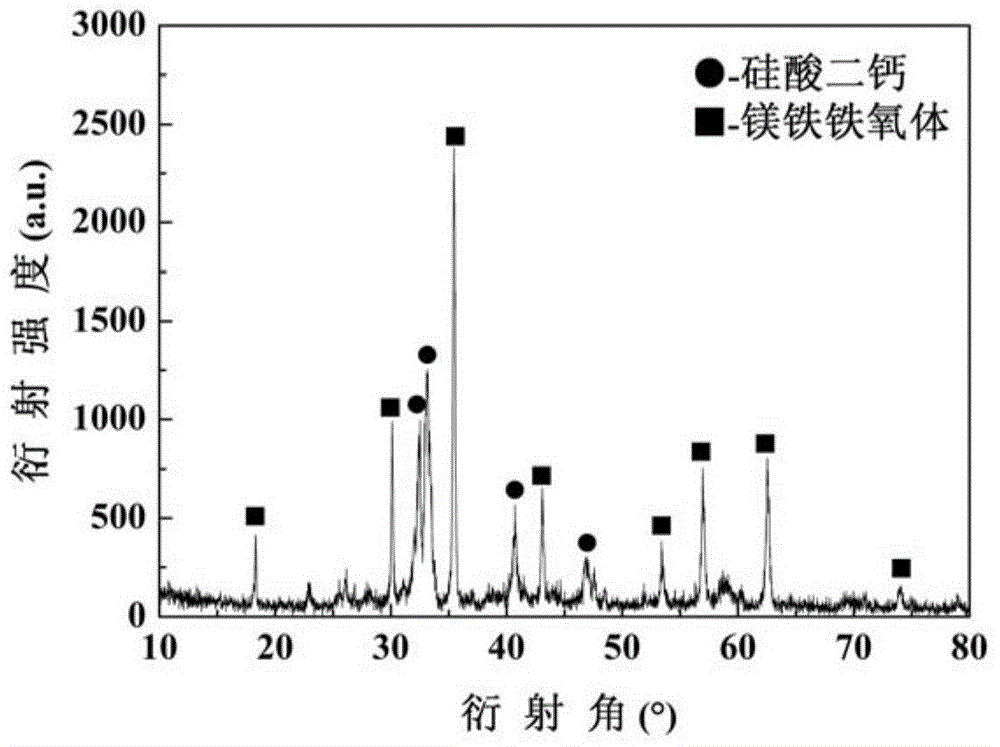

[0022] Take 50g of converter steel slag, and the silicon-rich material modifier is analytically pure SiO 2 , the dosage is 8% of the steel slag mass. Steel slag and SiO 2 After mixing evenly, put it in a MgO crucible, place it in a silicon-molybdenum rod heating furnace, raise the temperature to 1500°C for 30 minutes, cool down to 1250°C and keep it for 2 hours, then take out the slag sample and put it in water to quench it. The cooled slag sample was ball milled into powder, and the chemical composition and XRD spectrum were measured respectively. The results are shown in Table 2 and figure 1 .

[0023] Table 2 Doped with 8% SiO 2 The chemical composition of the modified steel slag wt%

[0024]

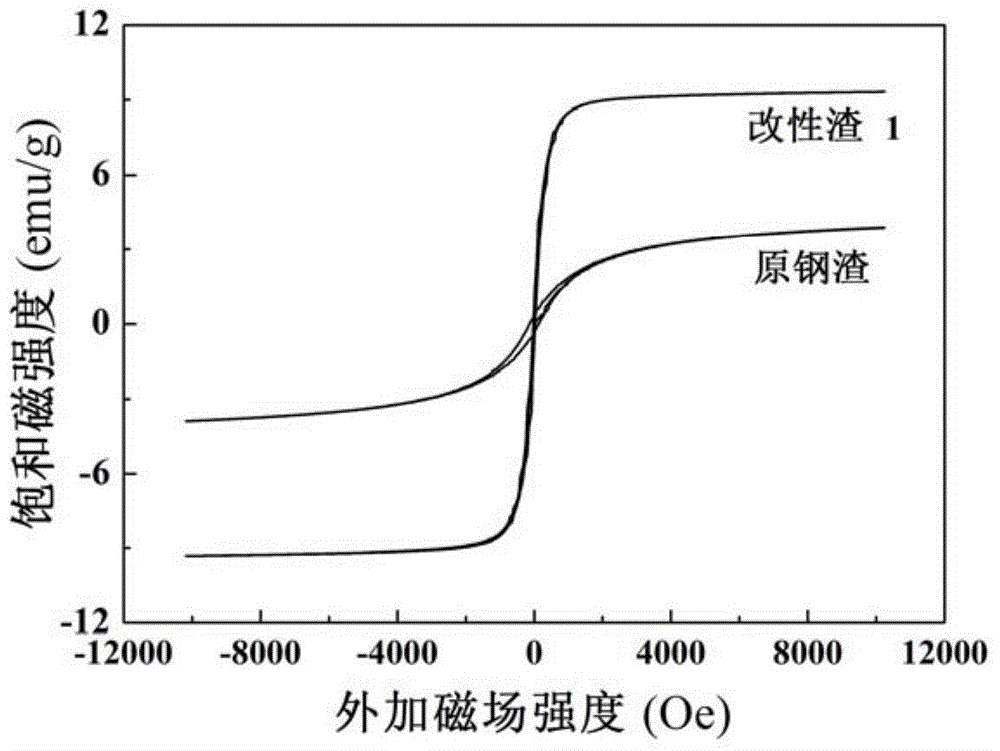

[0025] From figure 1 It can be seen that adding SiO 2 The modified steel slag contains no f-CaO, C 2 F diffraction peak, the main phase is dicalcium silicate C 2 S and magnesium iron ferrite (Mg, Fe) Fe 2 o 4 , and (Mg, Fe)Fe 2 o 4 is magnetic. The magnetic test resul...

Embodiment 2

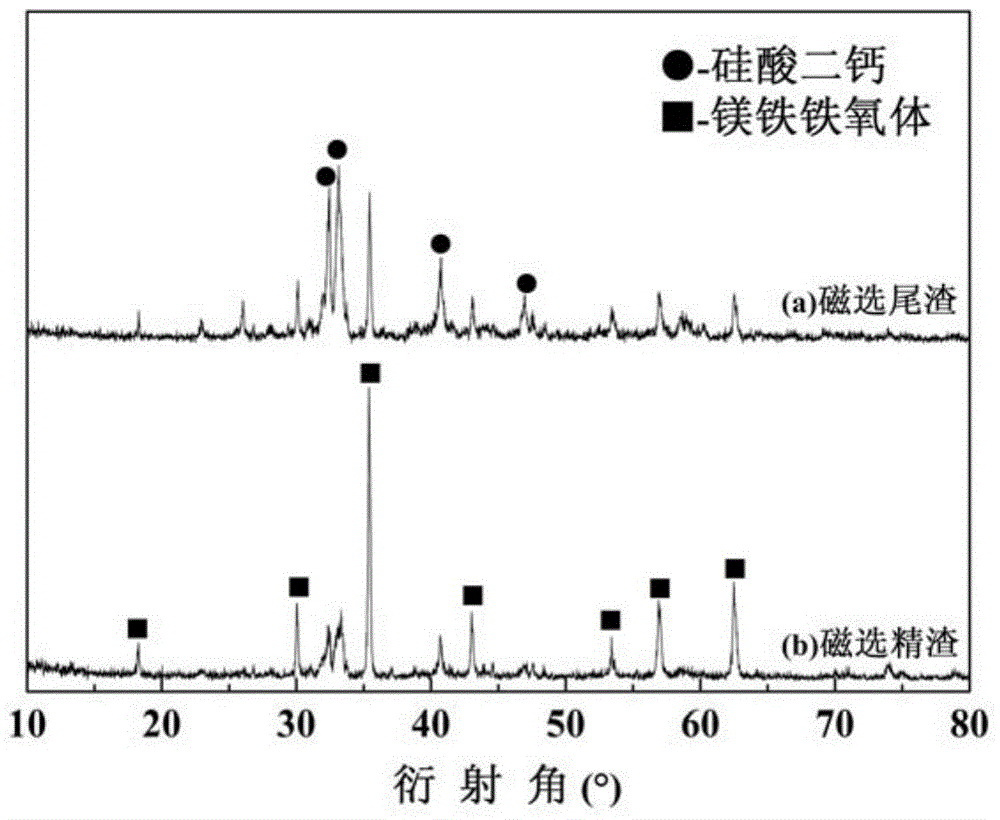

[0032] Take 50g of converter steel slag, the silicon-rich material modifier is fly ash, and the dosage is 15% of the mass of the steel slag. After mixing the steel slag and fly ash evenly, put it in a MgO crucible, place it in a silicon-molybdenum rod heating furnace, raise the temperature to 1400°C for 30 minutes, cool down to 1200°C and keep it for 2 hours, then take out the slag sample and put it in water for rapid cooling. The cooled slag sample was ball milled into powder, and the chemical composition and XRD spectrum were measured respectively. The results are shown in Table 4 and Figure 4 .

[0033] Table 4 The chemical composition wt% of the modified steel slag mixed with 15% fly ash

[0034]

[0035] From Figure 4 It can be seen that there is no f-CaO, C in the modified steel slag with fly ash 2 F Diffraction peak, except the main phase dicalcium silicate C 2 S and magnesium iron ferrite (Mg, Fe) Fe 2 o 4 In addition, tricalcium aluminate Ca 3 al 2 o 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com