Determination method of free calcium oxide in furnace slag

A free calcium oxide and determination method technology, which is applied in the preparation of test samples, chemical analysis by titration, etc., can solve the problems of many interfering elements, complex matrix components, and low measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

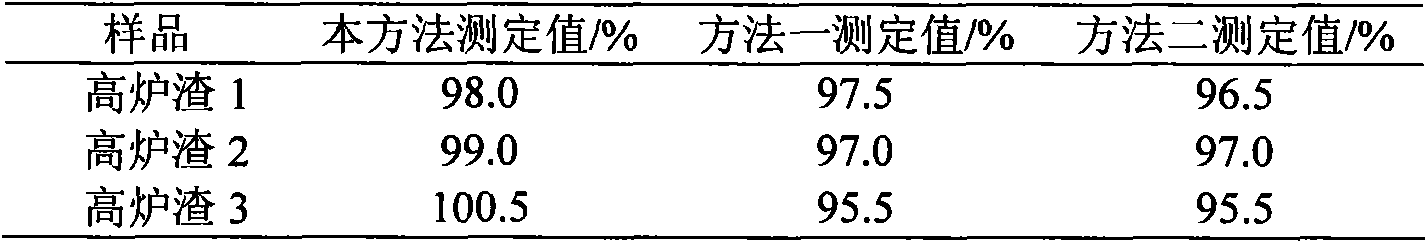

[0028] The mensuration of free calcium oxide in the blast furnace slag of embodiment 1:

[0029] Weigh 0.5g sample into a dry 250mL Erlenmeyer flask, add 90mL ethylene glycol-absolute ethanol solution, 0.2g sucrose, 10mL glycerin, place the Erlenmeyer flask on a shaker for 40min, and then place it on a constant temperature water bath Heat at 95°C for 40min. After the solution in the Erlenmeyer flask is cooled to room temperature, filter it into a 250mL volumetric flask with double-layer quantitative filter paper, wash the filter residue and the Erlenmeyer flask with absolute ethanol, then dilute to the mark with boiled and cooled deionized water, and mix well.

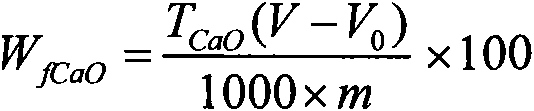

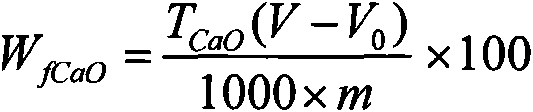

[0030] Draw 50.00mL of test solution into a 250mL beaker, add 50mL of water, 2 to 3 drops of magnesium chloride solution, 5mL of triethanolamine solution, 15mL of sodium hydroxide solution, and 0.1g of calcium indicator. After fully shaking, immediately titrate with EDTA standard titration solution to The solution tur...

Embodiment 2

[0041] The mensuration of free calcium oxide in the converter slag of embodiment 2:

[0042] Weigh 0.3g sample into a dry 250mL Erlenmeyer flask, add 80mL ethylene glycol-absolute ethanol solution, 0.1g sucrose, 5mL glycerin, place the Erlenmeyer flask on a shaker for 30min, and then place it on a constant temperature water bath Heat at 90°C for 30min. After the solution in the Erlenmeyer flask is cooled to room temperature, filter it into a 250mL volumetric flask with double-layer quantitative filter paper, wash the filter residue and the Erlenmeyer flask with absolute ethanol, then dilute to the mark with boiled and cooled deionized water, and mix well.

[0043] Draw 50.00mL of test solution into a 250mL beaker, add 50mL of water, 2 to 3 drops of magnesium chloride solution, 5mL of triethanolamine solution, 15mL of sodium hydroxide solution, and 0.1g of calcium indicator. After fully shaking, immediately titrate with EDTA standard titration solution to The solution turns fr...

Embodiment 3

[0054] The mensuration of free calcium oxide in the electric furnace slag of embodiment 3:

[0055] Weigh 0.8g sample into a dry 250mL Erlenmeyer flask, add 100mL ethylene glycol-absolute ethanol solution, 0.5g sucrose, 15mL glycerin, place the Erlenmeyer flask on a shaker for 60min, and then place it on a constant temperature water bath Heat at 110°C for 60min. After the solution in the Erlenmeyer flask is cooled to room temperature, filter it into a 250mL volumetric flask with double-layer quantitative filter paper, wash the filter residue and the Erlenmeyer flask with absolute ethanol, then dilute to the mark with boiled and cooled deionized water, and mix well.

[0056] Draw 50.00mL of test solution into a 250mL beaker, add 50mL of water, 2 to 3 drops of magnesium chloride solution, 5mL of triethanolamine solution, 15mL of sodium hydroxide solution, and 0.1g of calcium indicator. After fully shaking, immediately titrate with EDTA standard titration solution to The solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com