Deep belief network model based cement clinker free calcium content prediction method

A technology of deep belief network and cement clinker, which is applied in the field of prediction of clinker free calcium in cement firing system, can solve the problem that the free calcium content of cement cement is difficult to predict online in real time, and achieve the effect of reducing hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

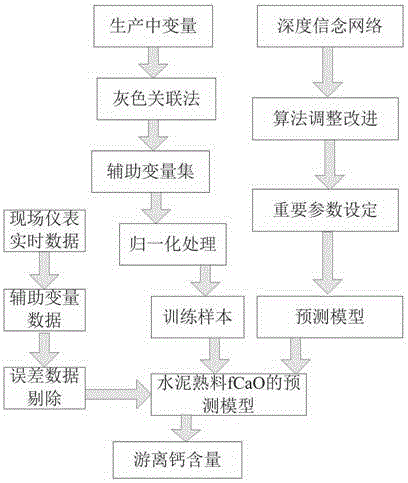

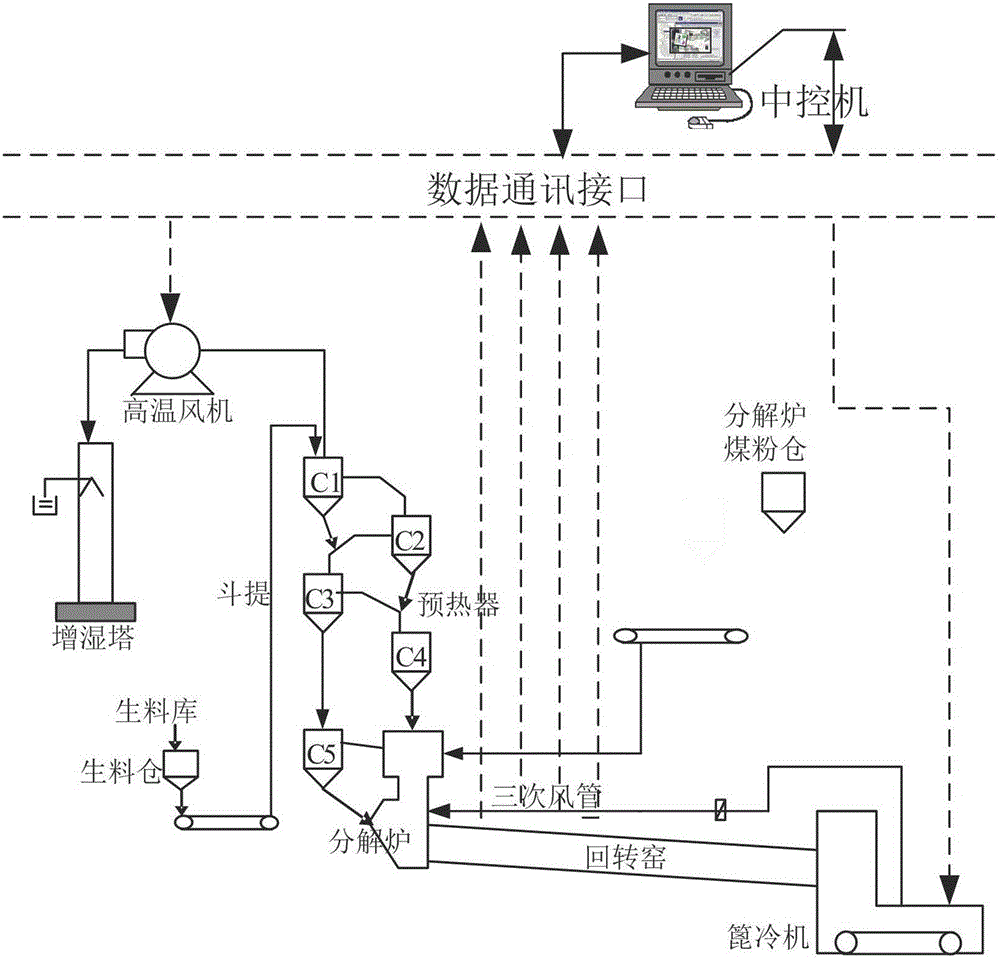

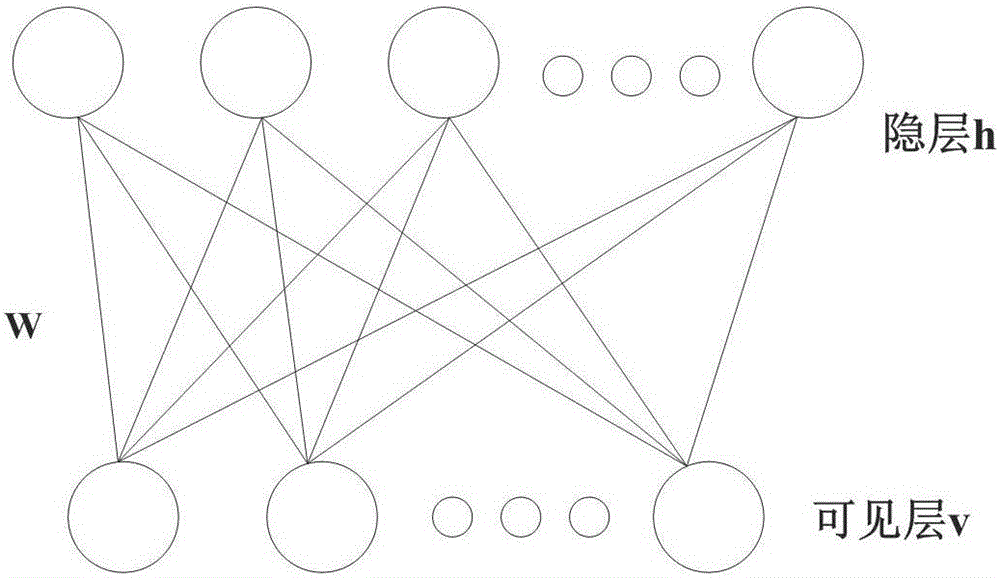

[0028] A prediction method for cement clinker fCaO content based on deep belief network model, figure 1 Shown is the on-site wiring diagram of the cement clinker free calcium prediction system based on the deep belief network model. First, the preliminary selection of auxiliary variables is carried out, and the collected data is combined with the deep belief network to establish the cement clinker free calcium prediction system of the present invention. A deep belief network model for calcium prediction, the block diagram of which is shown in image 3 Shown; The flow block diagram of cement clinker free calcium system based on deep belief network model prediction that the present invention proposes is as Figure 4 As shown, the backpropagation algorithm is used to correct the error of the deep belief network structure, and the learning flow chart of the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com