Performance adjustment material for activating steel slag at high temperature and application thereof

A high-temperature activation and steel slag technology, applied in the field of steel slag gelling, can solve the problems of little significance for large-scale application of steel slag, little room for performance improvement, and congenital deficiency of steel slag, so as to improve hydration and gelling activity, Guaranteed gelling performance and saving cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

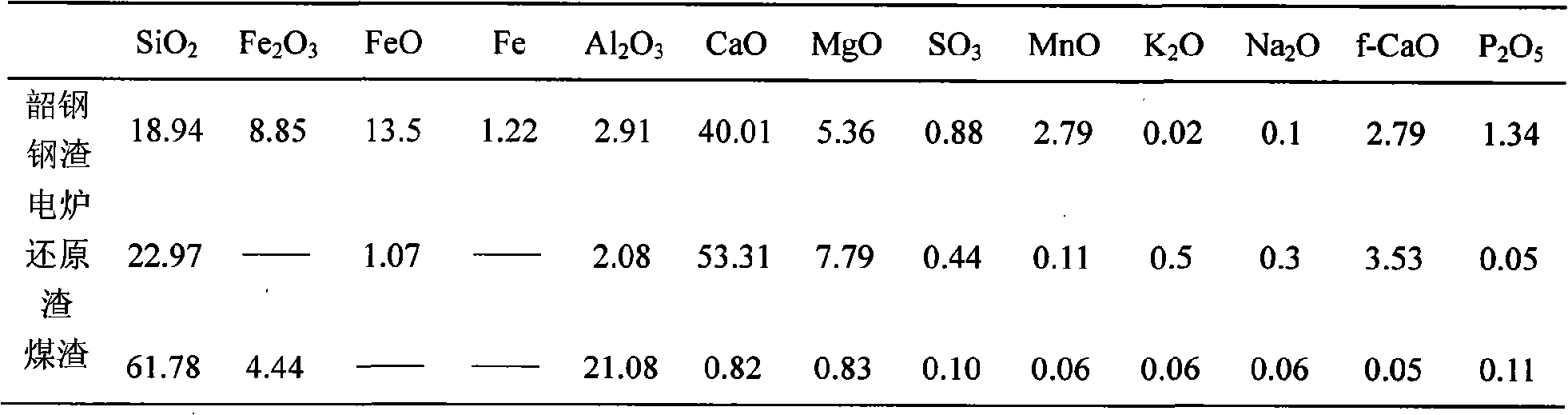

[0037] The parts by weight of each component of the performance adjustment material are as follows:

[0038] 95 parts (95 grams) of electric furnace reduced slag

[0039] 5 parts plastic-retaining starch (5g)

[0040] Applications of performance modulating materials:

[0041] 1. Mix the performance-adjusting material with the steel slag from Shaoguan Iron and Steel Company according to the following parts by weight:

[0042] Performance adjustment material 10 parts (100 grams)

[0043] Shaoguan Iron and Steel Company steel slag 90 parts (900 grams)

[0044] 2. Heat the mixture at 900°C for 60 minutes, so that the performance-adjusting material and steel slag undergo a reconstitution chemical reaction;

[0045] 3. The jaw crusher is used for crushing, and the reconstituted steel slag is separated by magnetic separation; finally, it is ground to a specific surface area of 415m 2 / kg.

example 2

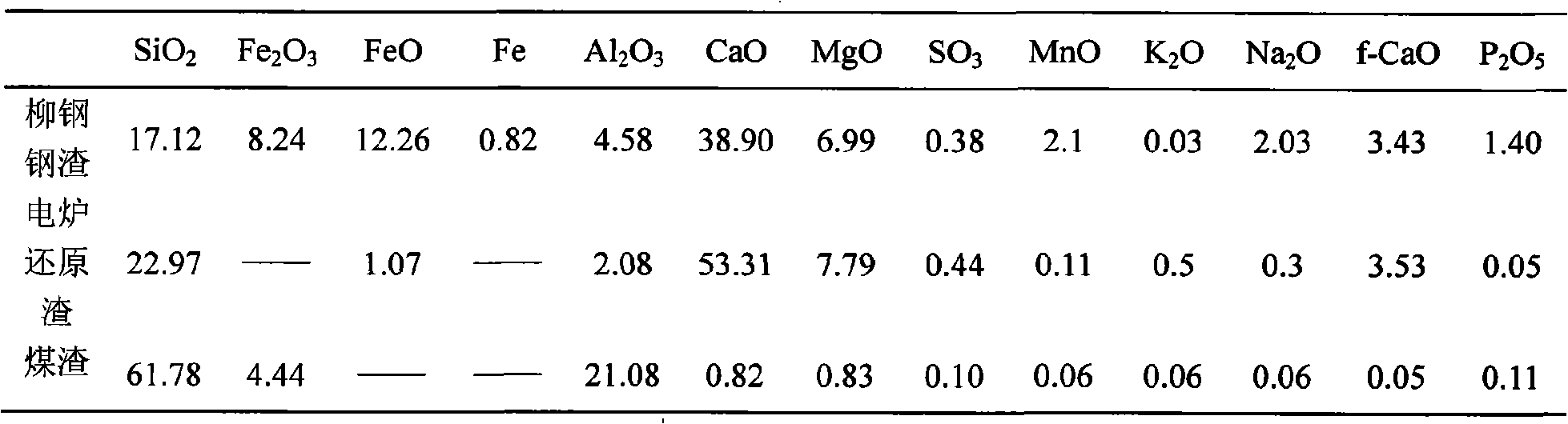

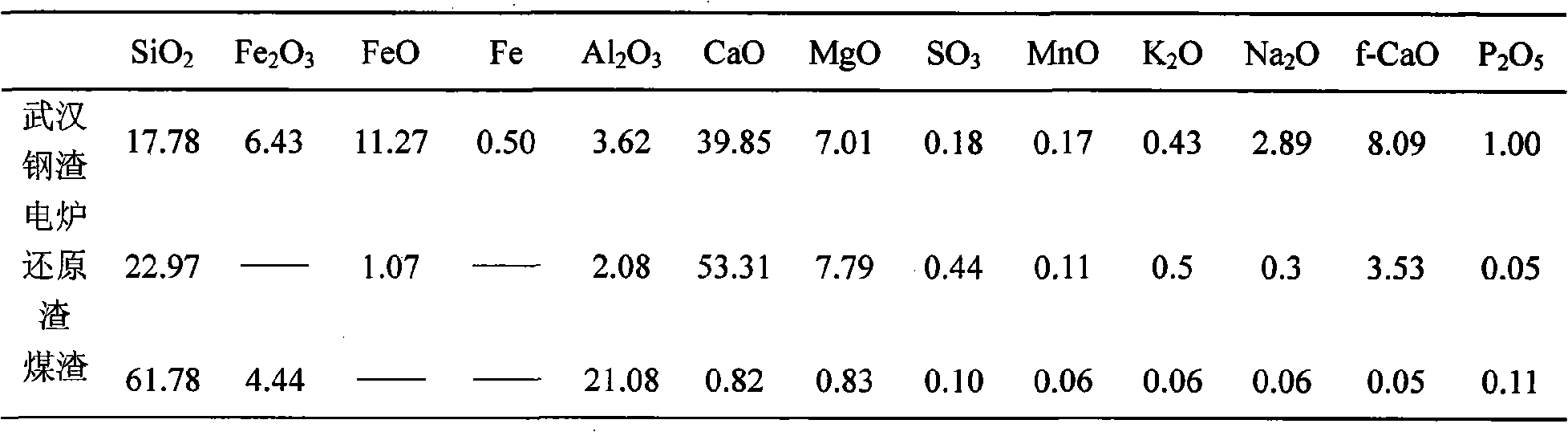

[0047] In this example, the chemical composition related to coal slag is as follows: (weight percent %)

[0048] The parts by weight of each component of the performance adjustment material are as follows:

[0049] 70 parts (140 grams) of electric furnace reduced slag

[0050] 27 cinders (54 grams)

[0051] 3 parts thickening starch (6g)

[0052] Applications of performance modulating materials:

[0053] 1. Mix the performance-adjusting material with the steel slag from Shaoguan Iron and Steel Company according to the following parts by weight:

[0054] 20 servings (200 grams) of performance conditioning material

[0055] Shaoguan Iron and Steel Company steel slag 80 parts (800 grams)

[0056] 2. Heat the mixture at 1150°C for 45 minutes to make the performance-adjusting material and steel slag undergo a reconstitution chemical reaction;

[0057] 3. The jaw crusher is used for crushing, and the reconstituted steel slag is separated by magnetic separation; finally, it is ...

example 3

[0059] The parts by weight of each component of the performance adjustment material are as follows:

[0060] Electric furnace reduced slag 50 parts (150 grams)

[0061] Cinder 49.5 parts (148.5 grams)

[0062] 0.5 parts (1.5 grams) of polyvinyl alcohol

[0063] Applications of performance modulating materials:

[0064] 1. Mix the performance-adjusting material with the steel slag from Shaoguan Iron and Steel Company according to the following parts by weight:

[0065] 30 servings (300 grams) of performance conditioning material

[0066] Shaoguan Iron and Steel Company steel slag 70 parts (700 grams)

[0067] 2. Heat the mixture at 1250°C for 30 minutes to make the performance-adjusting material and steel slag undergo a reconstitution chemical reaction;

[0068] 3. The jaw crusher is used for crushing, and the reconstituted steel slag is separated by magnetic separation; finally, it is ground to a specific surface area of 436m 2 / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com