Titanium gypsum waste residues composite cementing material and application thereof

A technology of composite cementitious material and titanium gypsum, applied in the field of building materials, can solve the problems of complex and diverse substances, affecting the hydration speed, etc., and achieve the effects of simple reaction process, improved hydration and hardening ability, and shortened setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

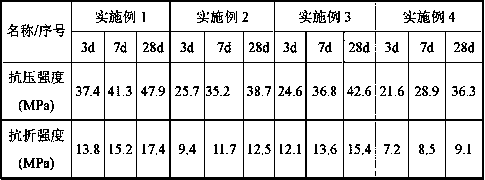

Examples

Embodiment 1

[0027] A titanium gypsum waste slag composite cementitious material, prepared from the following components in parts by weight:

[0028] Titanium gypsum: 40 parts;

[0029] Alkaline slag: 20 parts;

[0030] Portland cement: 35 parts;

[0031] Iron sulfate: 3 parts;

[0032] Amino superplasticizer: 2 parts;

[0033] Dry the titanium gypsum raw material at 210°C for 2 hours, crush it with a pulverizer at 3500 rpm for 2 hours, grind it, and pass it through a 250-mesh sieve; use a pulverizer at 1800 rpm for 1 hour, pass it through a 200-mesh sieve, and obtain a specific surface area of 400m 2 / Kg of slag and cement powder.

[0034] Applying the titanium gypsum waste slag composite cementitious material to building materials includes the following steps:

[0035] (1) Weigh the composite cementitious material according to a certain ratio, first place the titanium gypsum powder and ferric sulfate in a cement slurry mixer and stir at 40rpm for 15min, then add slag, Portland cem...

Embodiment 2

[0038] A titanium gypsum waste slag composite cementitious material, prepared from the following components in parts by weight:

[0039] Titanium gypsum: 56.5 parts;

[0040] Dolomite: 30 parts;

[0041] Portland cement: 10 parts;

[0042] Sodium dihydrogen phosphate: 1.5 parts;

[0043] Polycarboxylate superplasticizer: 2 parts;

[0044] Dry the titanium gypsum raw material at 200°C for 3 hours, crush it with a pulverizer at 3000rpm for 2 hours, grind it, and pass it through a 300-mesh sieve; use a pulverizer at 2000rpm for 2 hours, pass it through a 150-mesh sieve, and obtain a specific surface area of 380m 2 / Kg of dolomite and cement powder.

[0045] Applying the titanium gypsum waste slag composite cementitious material to building materials includes the following steps:

[0046] (1) Weigh the composite cementitious material according to a certain ratio, first place the titanium gypsum powder and sodium dihydrogen phosphate in a cement slurry mixer and stir at 25rp...

Embodiment 3

[0049] A titanium gypsum waste slag composite cementitious material, prepared from the following components in parts by weight:

[0050] Titanium gypsum: 70 parts;

[0051] Alkaline slag: 14 parts;

[0052] Portland cement: 10 parts;

[0053] Sodium dihydrogen sulfate: 2 parts;

[0054] Naphthalene superplasticizer: 4 parts;

[0055] Dry the titanium gypsum raw material at 150°C for 3 hours, crush it with a pulverizer at 4000rpm for 2 hours, grind it, and pass it through a 280-mesh sieve; use a pulverizer at 2800 rpm for 2 hours, pass it through a 210-mesh sieve, and obtain a specific surface area of 410m 2 / Kg of slag and cement powder.

[0056] Applying the titanium gypsum waste slag composite cementitious material to building materials includes the following steps:

[0057] (1) Weigh the composite cementitious material according to a certain ratio, first place the titanium gypsum powder and sodium dihydrogen sulfate in a cement slurry mixer and stir at 15rpm for 30min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com