Comprehensive utilization method for converter slag

A converter slag and residue technology, applied in the field of comprehensive utilization of converter slag, can solve environmental pollution and other problems, and achieve the effects of wide application range, wide sources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

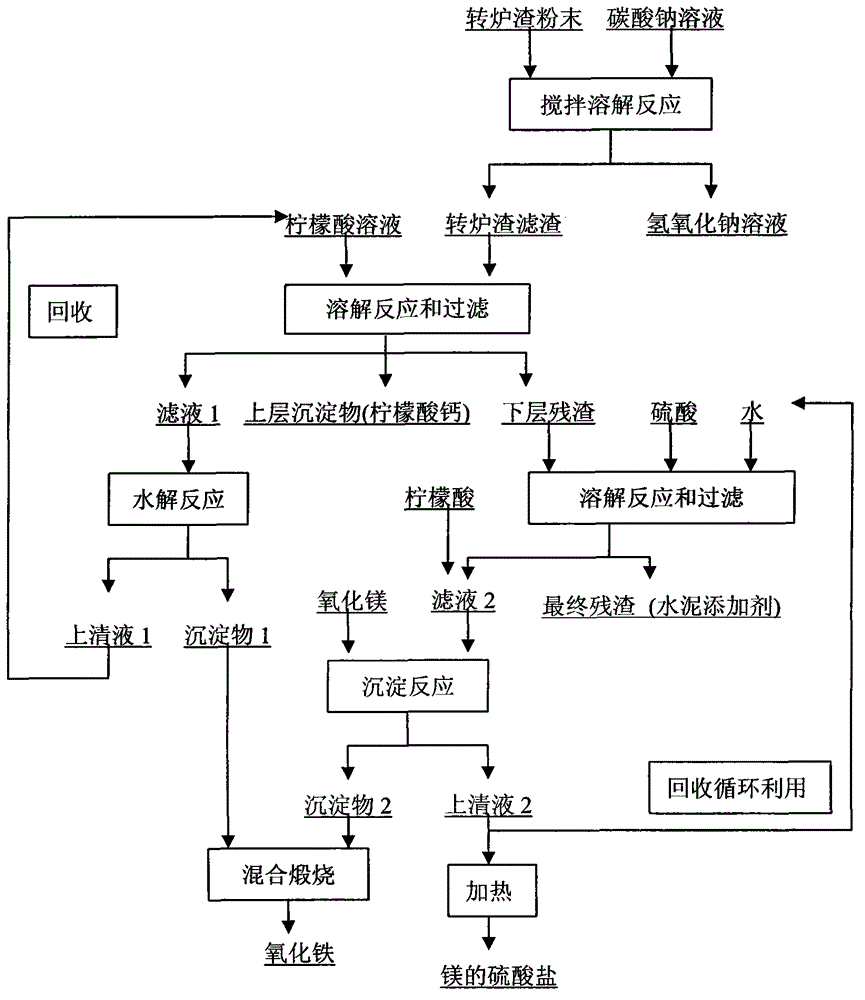

Method used

Image

Examples

Embodiment 1

[0040] (1) Pretreatment of converter slag: the converter slag (containing free calcium oxide accounts for 3% by weight, and the total amount of calcium element accounts for 23% by weight, and the total amount of iron element accounts for 24% by weight) Crush and grind to obtain a powder with a diameter of 50 μm, which is placed in a sodium carbonate solution for stirring and dissolving reaction. The dissolving reaction temperature is 35° C., and the dissolving reaction time is 20 minutes. The weight of sodium carbonate in the sodium carbonate solution is equal to the free calcium oxide in the converter slag powder 1.9 times of the weight, and the weight of water is 3.4 times of the weight of the converter slag powder. The reacted mixed solution is left to settle and filtered to obtain sodium hydroxide solution and converter slag filter residue, and the sodium hydroxide solution is heated and evaporated to dryness to obtain sodium hydroxide;

[0041] (2) Citric acid dissolution...

Embodiment 2

[0048] (1) Pretreatment of converter slag: the converter slag (containing free calcium oxide accounts for 4.6% by weight percentage, and the total amount of calcium element accounts for 34% by weight percentage, and the total amount of iron element accounts for 17% by weight percentage) Crush and grind to obtain a powder with a diameter of 170 μm, place it in a sodium carbonate solution for stirring and dissolving reaction, the dissolving reaction temperature is 60°C, and the dissolving reaction time is 60 minutes, the weight of sodium carbonate in the sodium carbonate solution is equal to the free calcium oxide in the converter slag powder 1.7 times of the weight, the weight of water is 2 times of the weight of the converter slag powder. The reacted mixed solution is left to settle and filtered to obtain sodium hydroxide solution and converter slag filter residue, and the sodium hydroxide solution is heated and evaporated to dryness to obtain sodium hydroxide;

[0049] (2) Ci...

Embodiment 3

[0056] (1) Pretreatment of converter slag: the converter slag (containing free calcium oxide accounts for 5.1% by weight, and the total amount of calcium element accounts for 28% by weight, and the total amount of iron element accounts for 28% by weight) Crushed and ground to obtain a powder with a diameter of 120 μm, placed in a sodium carbonate solution for stirring and dissolving reaction, the dissolving reaction temperature was 80°C, the dissolving reaction time was 40 minutes, and the weight of sodium carbonate in the sodium carbonate solution was equal to the free calcium oxide in the converter slag powder 1.76 times of the weight, and the weight of water is 2.9 times of the weight of the converter slag powder. The reacted mixed solution is left to settle and filtered to obtain sodium hydroxide solution and converter slag filter residue, and the sodium hydroxide solution is heated and evaporated to dryness to obtain sodium hydroxide;

[0057] (2) Citric acid dissolution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com