Method for fixing carbon dioxide and digesting free calcium oxide in slag micro powder

A technology of free calcium oxide and steel slag micropowder, applied in separation methods, chemical instruments and methods, calcium carbonate/strontium/barium, etc., to achieve the effects of improving work performance and durability, reducing emissions and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

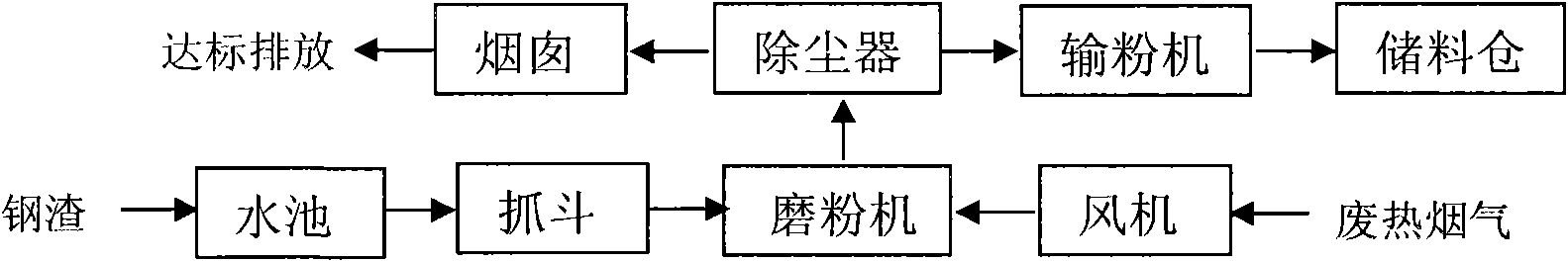

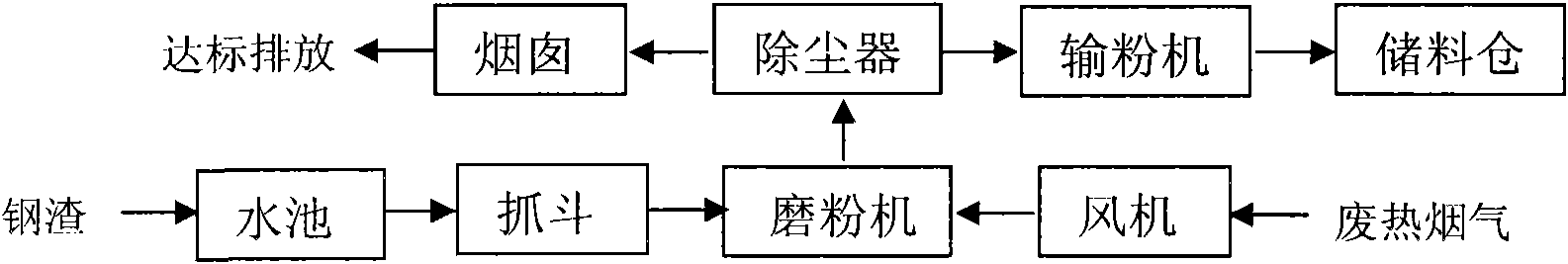

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Add 5 kg of steel slag tailings with a free calcium oxide content of 6.26% into the ball mill, add 5 kg of water, and feed CO 2 The content is 800mg / Nm 3 , the flow rate is 1.8Nm 3 / h of CO 2 Mixed gas with air, treatment time is 1 hour. The free calcium oxide content of the treated steel slag fine powder is 1.62%, and the free calcium oxide digestion rate reaches 74.1%. Using this method, 36.5kg of carbon dioxide can be fixed per ton of steel slag.

Embodiment 2

[0024] Example 2: Add 5 kg of steel slag tailings with a free calcium oxide content of 6.26% into the ball mill, add 5 kg of water, and feed CO 2 The content is 800mg / Nm 3 , the flow rate is 1.8Nm 3 / h of CO 2 Mixed gas with air, treatment time is 3 hours. The free calcium oxide content of the treated steel slag fine powder is 0.10%, and the free calcium oxide digestion rate reaches 98.4%. Using this method, 48.4kg of carbon dioxide can be fixed per ton of steel slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com