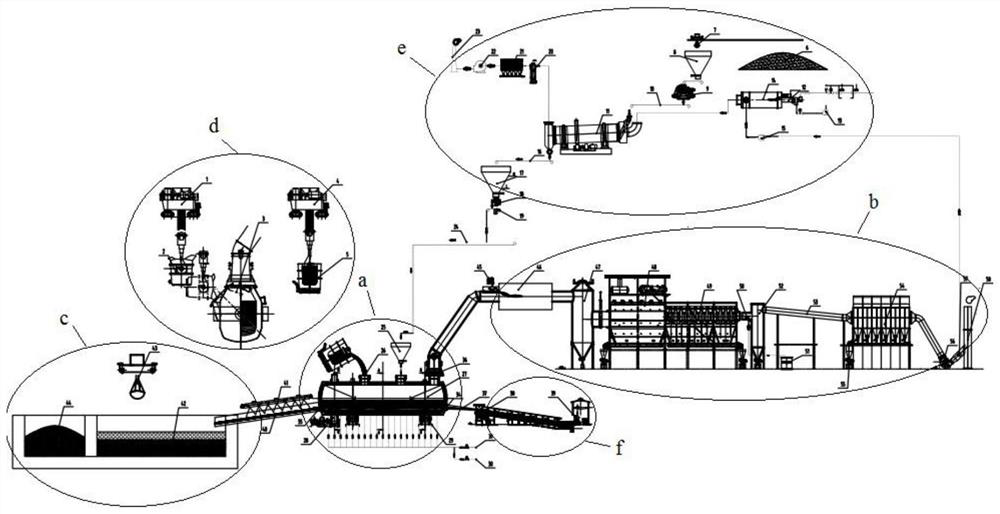

Steel slag and laterite-nickel ore collaborative quenching and tempering treatment device and method

A lateritic nickel ore quenching and tempering treatment technology, which is applied in the field of iron and steel metallurgy, can solve the problems of low grade, high production cost, and uneconomical, and achieve the effects of short operation cycle, high waste heat utilization rate, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] This example takes a steel factory with an annual output of 4 million tons of steel as an example. The annual output of converter steel slag is 400,000 tons, and the average steel slag discharge rate is 47.62t / h. The hot stuffy slag method was used originally, and the slag utilization rate is about 20%. Now The steel slag is quenched and tempered by the method of synergistic conditioning treatment of steel slag and laterite nickel ore, and 1# high-nickel and low-iron laterite nickel ore is added as a conditioning agent.

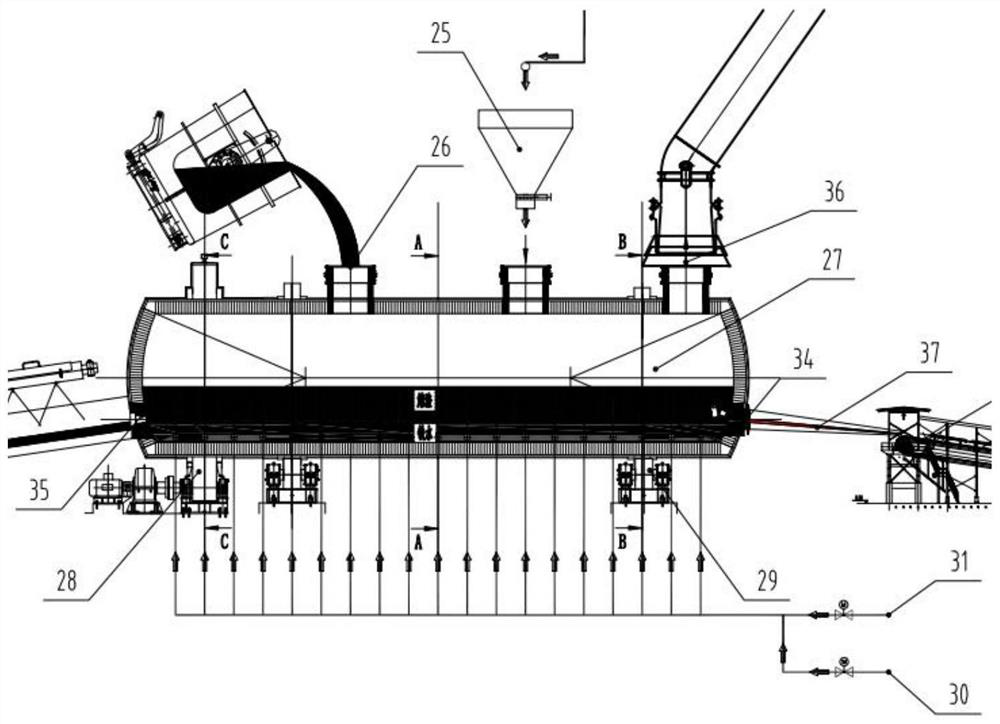

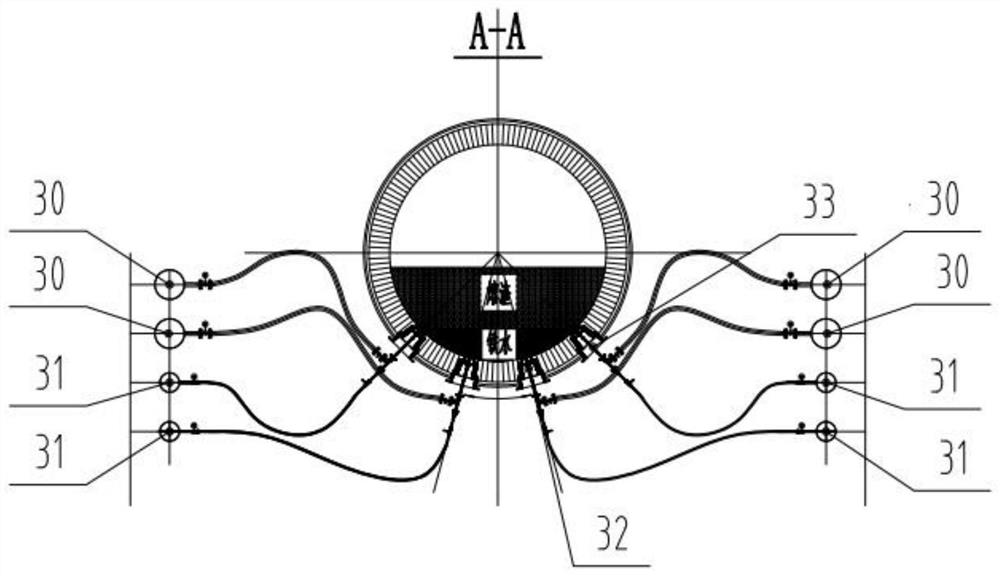

[0108] Pour liquid molten steel slag at 1550-1600°C (enthalpy is about 56kg standard coal / t-slag) into the tempering furnace, and mix it with dried 1# high-nickel and low-iron laterite nickel ore (water content is less than 1%), and carry out 60min quenching and tempering treatment. The conditioning process uses full oxygen or oxygen-enriched air as the carrier, and injects coal powder by adjusting the bottom-blown coal oxygen lance and side-blown coal...

Embodiment 2

[0140] Referring to Table 6, the present embodiment processes 400,000 tons of steel slag and 460,000 tons of 2# low-nickel and high-iron laterite nickel ore annually, totaling 860,000 tons, with a total iron content of 20.88% in the steel slag, and 2# low-nickel and high-iron laterite-nickel ore all-iron The content is 44.58%. The steel slag is quenched and tempered by the method of synergistic quenching and tempering treatment of steel slag and lateritic nickel ore mentioned above. Iron oxides are reduced (1550-1600°C) into liquid metal iron through the quenching and tempering furnace bath, and the yield of iron metal is 97.55% %.

[0141] Table 6 Composition and treatment amount of steel slag and 2# low nickel high iron laterite nickel ore

[0142]

[0143] Continued Table 6 Steel slag and 2# low nickel high iron laterite nickel ore composition and processing capacity

[0144]

[0145] Table 7 shows the composition and quantity of pig iron and slag after quenching and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com