A kind of construction waste regenerated highly active mineral admixture and its preparation

A mineral admixture, high activity technology, applied in clinker production, cement production, etc., can solve the problems of wasting land resources, occupying land resources, secondary pollution, etc., and achieve low manufacturing cost, simple ingredients, and easy production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation process of recycled highly active mineral admixture:

[0030] Take 70-98wt% of cement stone powder, 0-25wt% of metallurgical waste residue and 0-5%wt of floating beads and mix them, add water accounting for 10-15% of the total mass of cement stone powder, metallurgical waste residue and floating beads, and then bake drying to obtain slag powder; calcining the obtained slag powder at a temperature range of 800° C. to 1000° C. for 15 to 20 minutes to obtain calcined slag powder.

[0031] Using wet mixing method to process raw materials can make Ca(OH) in cement stone powder 2 React with highly active siliceous raw material metallurgical waste slag and floating beads to produce more C-S-H, at the same time, due to the reaction consumes some Ca(OH) in cement stone powder 2 , to some extent reduce the content of CaO in the recycled mineral admixture. Further, during thermal decomposition of cement stone powder, a considerable part of [SiO 4 ] tetrahedral chain...

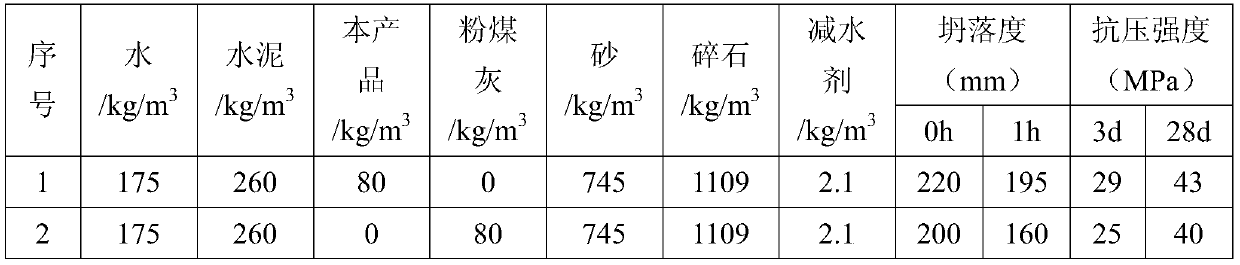

Embodiment 1

[0037] Use the waste concrete (strength grade C30~C60) recovered from building demolition to crush the concrete and separate the gravel and mortar, and then use the jaw crusher to crush the mortar into particles with a particle size of less than 8mm; then use a ball mill to grind to the specific surface area 300m 2 / kg of cement stone powder for use.

[0038] Mix cement stone powder, metallurgical waste slag and floating beads evenly through a mixer (by mass fraction, cement stone powder 70%, metallurgical waste slag 25%, floating beads 5%), add water accounting for 10% of the total mass fraction of the three and mix thoroughly Chemical and drying to obtain slag powder; the obtained slag powder was calcined at 850°C for 20 minutes to obtain calcined slag powder; the calcined slag powder was ground to a specific surface area of 400m 2 / kg spare.

[0039] In terms of mass percentage, 50wt% of the above-mentioned standby calcined slag stone powder and a specific surface area ...

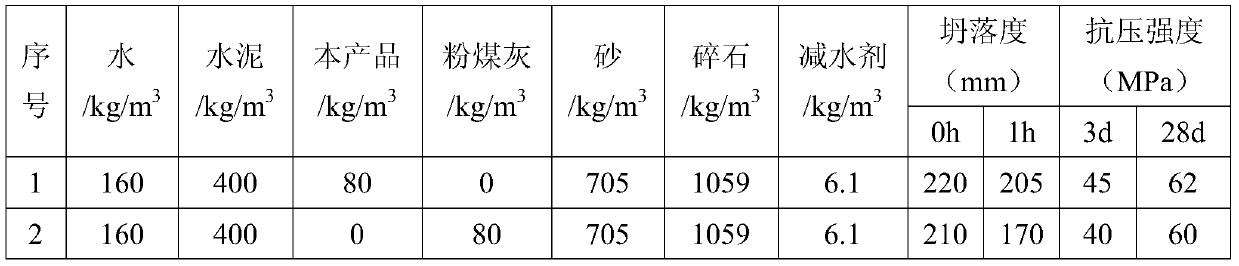

Embodiment 2

[0049] Use the waste concrete (strength grade C30~C60) recovered from building demolition to crush the concrete and separate the gravel and mortar, and then use the jaw crusher to crush the mortar into particles with a particle size of less than 8mm; then use a ball mill to grind to the specific surface area 400m 2 / kg of cement stone powder for use.

[0050] Mix cement stone powder, metallurgical waste slag and floating beads evenly through a mixer (by mass fraction, cement stone powder 80%, industrial metallurgical waste 18%, floating beads 2%), add water accounting for 15% of the total mass fraction of the three and mix thoroughly Homogenize and dry to obtain slag powder; the obtained slag powder is calcined at 900°C for 15 minutes to obtain calcined slag powder; the calcined slag powder is ground to a specific surface area of 400m 2 / kg spare.

[0051] In terms of mass percentage, take the above-mentioned spare calcined slag stone powder 70wt% and specific surface area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com