Anticorrosion high-belit sulfoaluminate cement clinker and preparation method thereof, anticorrosion high-belit sulfoaluminate cement and preparation method of cement

A technology of special sulfoaluminate and cement clinker, which is applied in the field of corrosion-resistant high-belite sulfoaluminate cement and its preparation, and the field of corrosion-resistant high-belite sulfoaluminate cement clinker and its preparation. Solve the problems of poor seawater erosion resistance and poor abrasion resistance, and achieve the effects of improving seawater erosion resistance and abrasion resistance, high early strength and controllable early hydration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

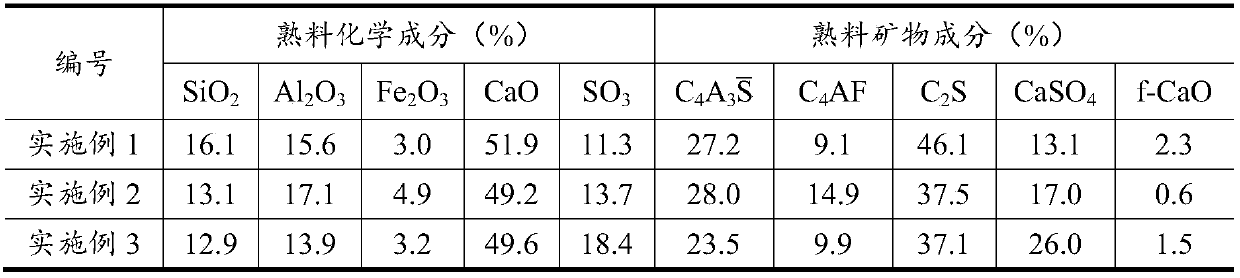

[0073] Another aspect of the present invention provides a method for preparing the above-mentioned corrosion-resistant high belite sulfoaluminate cement clinker, comprising the following steps:

[0074] The raw materials containing silicon, aluminum, sulfur, calcium and iron are mixed according to the content of the above mineral components, and the corrosion-resistant high belite sulfoaluminate cement clinker is obtained after high-temperature reaction.

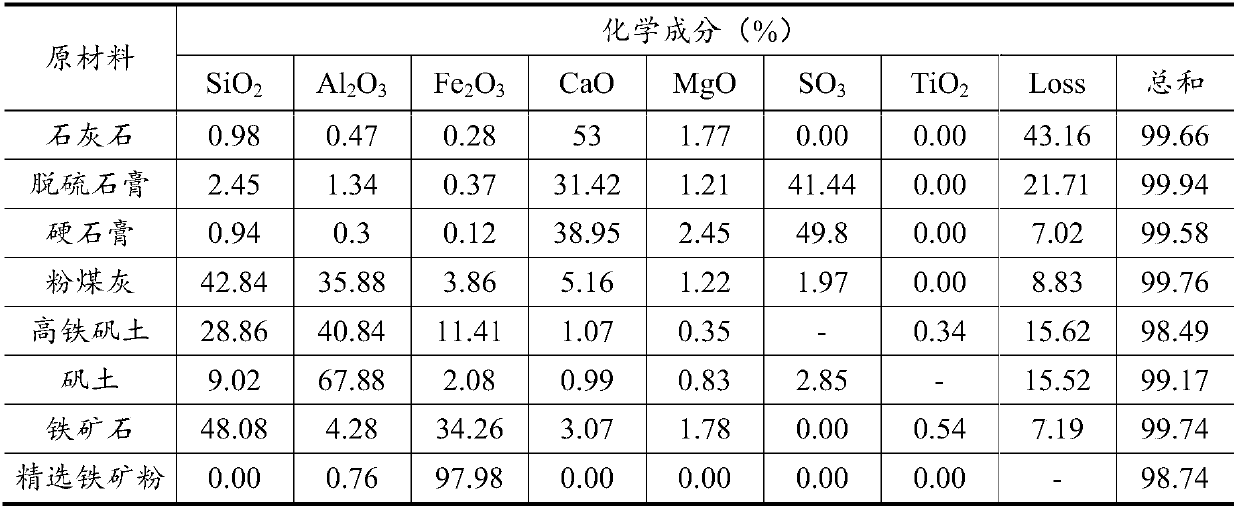

[0075] Here, the raw material containing silicon, aluminum, sulfur, calcium and iron preferably refers to oxides of silicon, oxides of aluminum, oxides of sulfur, oxides of calcium and oxides of iron.

[0076] By optimizing the chemical composition of the raw materials, the content of each mineral composition obtained after the reaction is more accurate, so as to improve the performance of the corrosion-resistant high belite sulfoaluminate cement clinker.

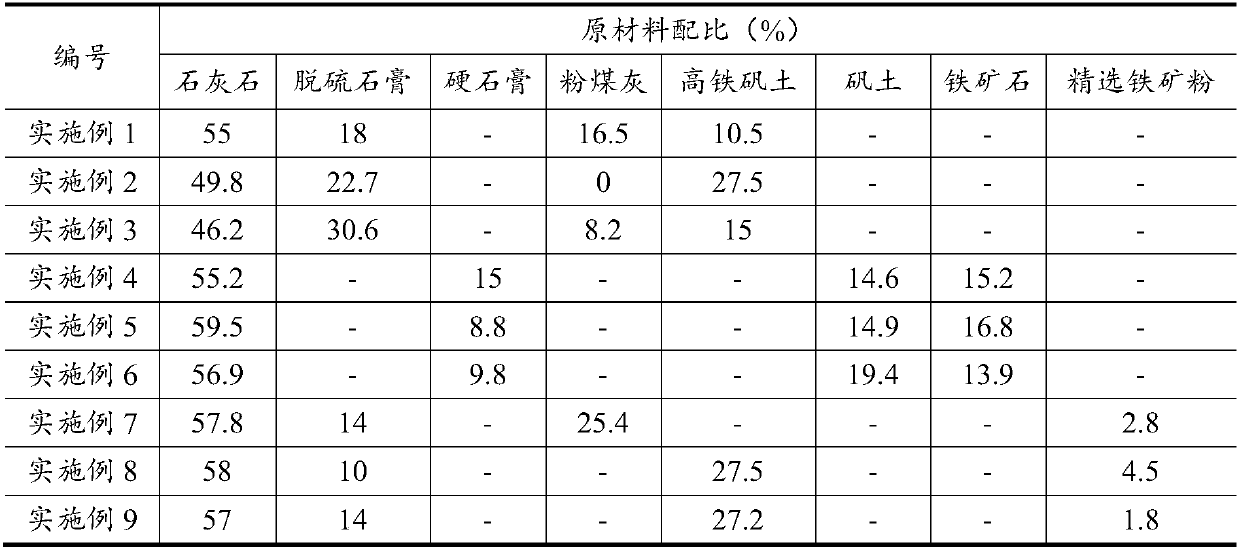

[0077] As a preferred embodiment of the present invention, the raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com