Method for determining content of free calcium oxide in steel slag

A technology of free calcium oxide and a determination method, which is applied in the field of determination of free calcium oxide content in steel slag, can solve the problems of inaccurate measured data, difficult operation, and inability to truly reflect the real content of free calcium oxide, and achieves a short time , accurate results

Inactive Publication Date: 2014-02-05

HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, some measurement methods currently used not only require professional large-scale measurement equipment, but are not easy to implement in operation, and the measured data are not accurate, and cannot truly reflect the true content of free calcium oxide.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

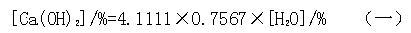

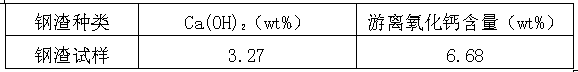

The invention discloses a method for determining the content of free calcium oxide in steel slag. The method comprises the following steps: 1, carrying out heating decomposition of a steel slag sample in inert atmosphere, and using a weight loss caused by the water volatilization during the heating decomposition of the slag sample to calculate the content of Ca(OH)2; 2, determining the content of free total calcium in the steel slag sample subjected to the heating decomposition; and 3, subtracting the Ca(OH)2 content by the amount of the free total calcium to obtain the content of the free calcium oxide. The determination utilizing a principle that calcium oxide can be generated after heating Ca(OH)2 is characterized in that a water evaporation weight loss method is used to calculate the content of calcium hydroxide (Ca(OH)2), a simple easy-implementation determining method is used to determine the amount of free total calcium, and finally an accurate free calcium oxide value is obtained. The determination method disclosed in the invention changes a present situation of the result inaccuracy caused by the interference of Ca(OH)2, and has the characteristics of short use time, accurate result, and maneuverability of all above processes.

Description

technical field The invention relates to the field of measuring steel slag, in particular to a method for measuring free calcium oxide content in steel slag. Background technique The iron and steel industry is the main pillar economic industry in my country, and steel slag is the main solid waste of iron and steel enterprises, and tens of millions of tons of steel slag are produced every year. Steel slag contains dicalcium silicate, tricalcium silicate and a small amount of free calcium oxide and free magnesium oxide, etc., so it has certain gelling properties, but the small amount of free calcium oxide and free magnesium oxide in steel slag hydrates slowly, so it is used in When building materials are used in hydration, the building will crack due to late hydration, which will affect the stability of the building. Therefore, the stability of the steel slag should be solved before it is used. At present, the domestic methods used to measure the content of free calcium oxid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N5/04

Inventor 郭景瑞孙玉虎李玉银徐晓王晓晖卜二军朱文玲孟令峰方小霞

Owner HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com