Method for removing organic matters in byproduct carbon black of acetylene preparation through partial oxidation of natural gas

A technology of natural gas and by-products, applied in the direction of fibrous fillers, etc., can solve the problems that the by-product carbon black of acetylene cannot be used directly, the application effect of carbon black products is not ideal, and the gaps of carbon black are blocked, so as to improve the light transmittance of toluene, The effect of improving resource utilization and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

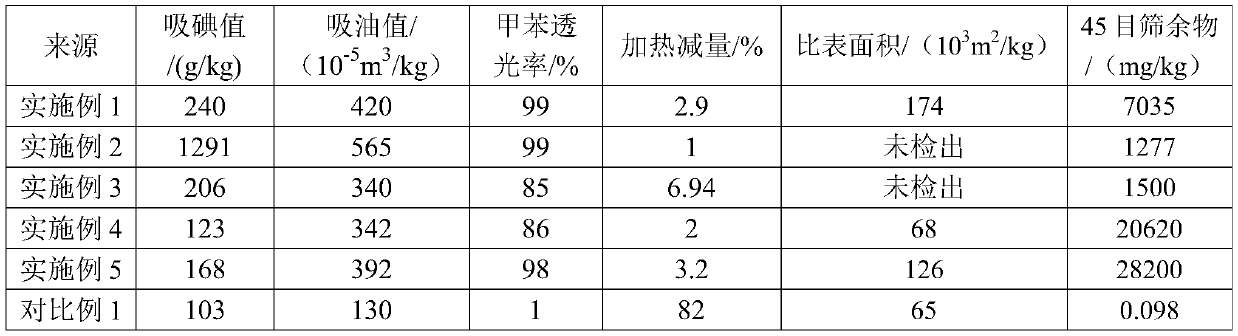

Embodiment 1

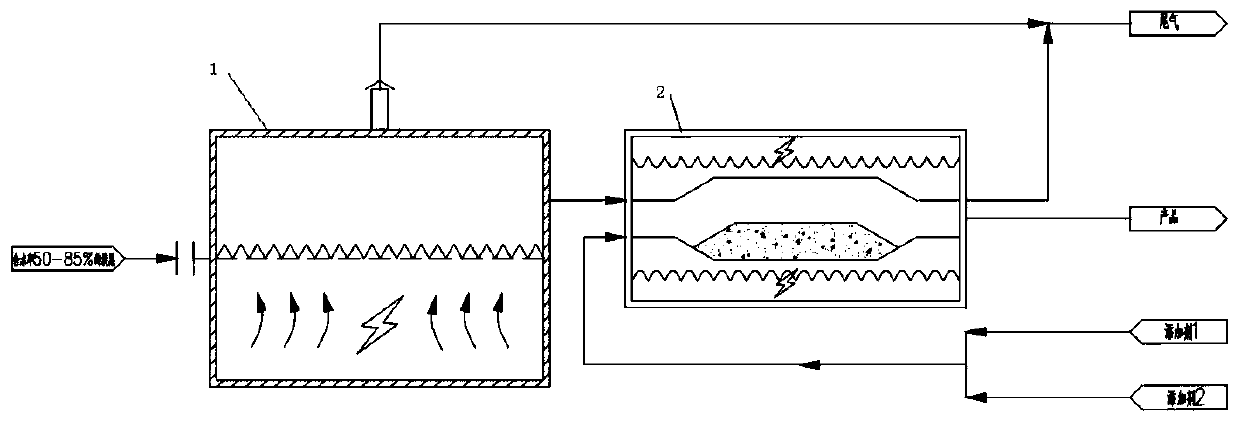

[0042] according to figure 1 The shown flow process removes the organic matter in the acetylene by-product carbon black, and the specific process flow is:

[0043] A. drying: put the carbon black (the by-product from the partial oxidation of natural gas to acetylene) with a moisture content of 50% in the electric heating drying equipment at 100°C, so that the moisture content of the carbon black is reduced to 30%;

[0044] B. Remove: control the relative pressure of the activation furnace to be 0.4MPa, and isolate oxygen, air and ozone, fill the carbon black with a moisture content of 30% into the activation furnace, add 1.12% nitrogen of the carbon black quality, and the activation furnace is heated up to 500°C, and react at 500°C for 90 minutes; after the reaction, add water vapor with 2.37% carbon black mass into the activation furnace, and raise the temperature of the activation furnace to 900°C, and react at 900°C for 150 minutes.

Embodiment 2

[0046] according to figure 1 The shown flow process removes the organic matter in the acetylene by-product carbon black, and the specific process flow is:

[0047] A. drying: put the carbon black (the by-product from the partial oxidation of natural gas to acetylene) with a moisture content of 85% in the steam heating drying equipment at 125°C, so that the moisture content of the carbon black is reduced to 25%;

[0048] B. Removal: Control the relative pressure of the activation furnace to be 0MPa, and isolate oxygen, air and ozone, fill the carbon black with a moisture content of 30% into the activation furnace, add helium with 5% carbon black quality, and the activation furnace is heated to 800°C, and react at 800°C for 60 minutes; after the reaction, add carbon dioxide with 7.9% carbon black mass into the activation furnace, and raise the temperature of the activation furnace to 950°C, and react at 950°C for 30 minutes.

Embodiment 3

[0050] according to figure 1 The shown flow process removes the organic matter in the acetylene by-product carbon black, and the specific process flow is:

[0051] A. Drying: put the carbon black (from the by-product of acetylene produced by partial oxidation of natural gas) with a moisture content of 60% in 110°C steam heating and drying equipment, so that the moisture content of the carbon black is reduced to 20%;

[0052] B. Removal: Control the relative pressure of the activation furnace to be 0.2MPa, and isolate oxygen, air and ozone, fill the activation furnace with carbon black with a moisture content of 20%, add radon gas with a mass of 3% of carbon black, and heat up the activation furnace to 150°C, and react at 150°C for 90 minutes; after the reaction, add calcium carbonate with 3% carbon black mass into the activation furnace, and raise the temperature of the activation furnace to 900°C, and react at 900°C for 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com