Calcined kaolin with high whiteness and high oil-absorbing value as well as preparation method thereof

A technology for calcined kaolin and high oil absorption, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems that calcined kaolin cannot meet high whiteness and high oil absorption at the same time, and the production cost is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

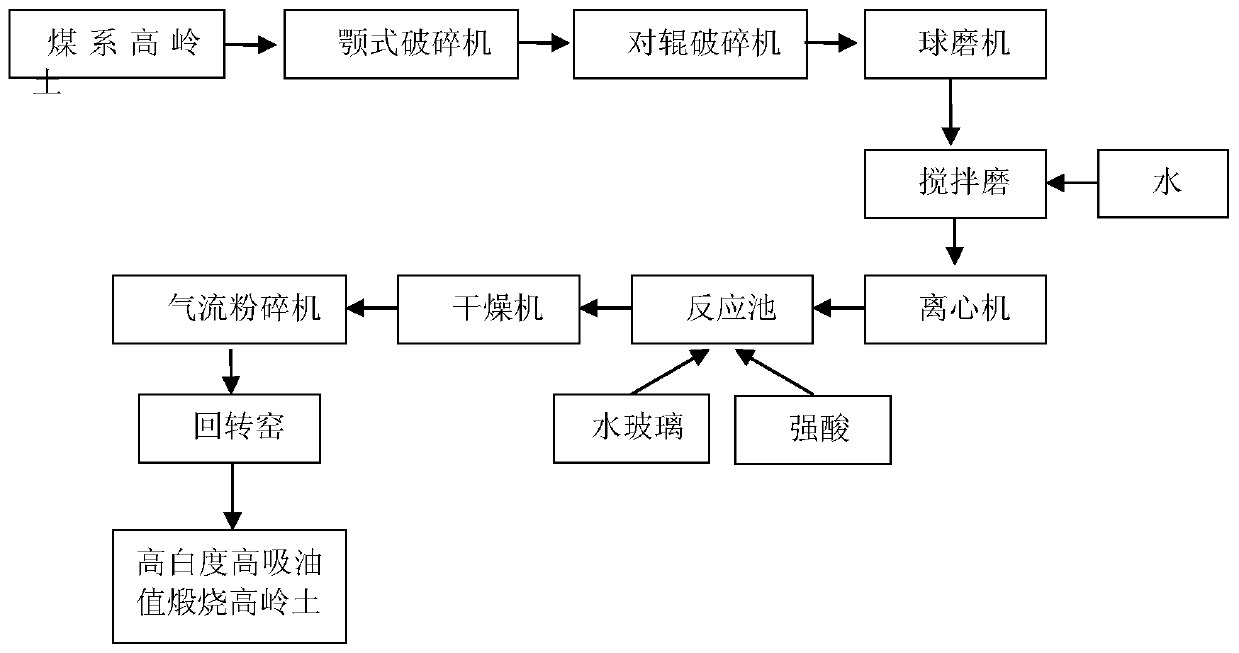

Image

Examples

Embodiment 1

[0041] The calcined kaolin with high whiteness and high oil absorption value in this embodiment includes calcined kaolin and white carbon black adsorbed on the surface of the calcined kaolin, and the white carbon black is 0.5% of the mass of the calcined kaolin. Calcined kaolin with an average particle size of 2 μm. High whiteness and high oil absorption Calcined kaolin has a whiteness of 94% and an oil absorption of 81g / 100g.

[0042] The preparation method of calcined kaolin with high whiteness and high oil absorption value in this embodiment:

[0043] The No. 1 coal series kaolin raw material is coarsely ground in a jaw crusher and a roller crusher, then finely ground in a ball mill, then superfinely ground in a stirring mill with water, and centrifuged until at least 80% of the kaolin is obtained. Coal series kaolin raw material slurry with particle size less than 2 μm;

[0044] Be that the water glass of 10% mass concentration and the sulfuric acid that mass concentrati...

Embodiment 2

[0046] The calcined kaolin with high whiteness and high oil absorption value in this embodiment includes calcined kaolin and white carbon black adsorbed on the surface of the calcined kaolin, and the white carbon black is 1% of the mass of the calcined kaolin. Calcined kaolin with an average particle size of 2 μm. High whiteness and high oil absorption calcined kaolin has a whiteness of 95% and an oil absorption of 84g / 100g.

[0047] The preparation method of calcined kaolin with high whiteness and high oil absorption value in this embodiment:

[0048] The No. 1 coal series kaolin raw material is first coarsely ground by a jaw crusher, coarsely ground by a roller crusher, then finely ground in a ball mill, and then superfinely ground in a stirring mill with water, and centrifuged until at least 80 % coal-measure kaolin raw material slurry with particle size less than 2 μm;

[0049] Be that the water glass of 10% mass concentration and the nitric acid of 30% mass concentratio...

Embodiment 3

[0051] The calcined kaolin with high whiteness and high oil absorption value in this embodiment includes calcined kaolin and white carbon black adsorbed on the surface of the calcined kaolin, and the white carbon black is 0.5% of the mass of the calcined kaolin. Calcined kaolin with an average particle size of 2 μm. High whiteness and high oil absorption value Calcined kaolin has a whiteness value of 95% and an oil absorption value of 86g / 100g.

[0052] The preparation method of calcined kaolin with high whiteness and high oil absorption value in this embodiment:

[0053] The No. 2 coal series kaolin raw material is first coarsely ground in a jaw crusher and a roller crusher, then finely ground in a ball mill, then superfinely ground in a stirring mill with water, and centrifuged until at least 80% of the kaolin is obtained. Coal series kaolin raw material slurry with particle size less than 2 μm;

[0054]Be that the water glass of 10% mass concentration and the sulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com