Preparation method of coated conductive whisker/composite antistatic coating

An antistatic and coating technology, applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor dyeability, and achieve the effect of ensuring antistatic performance and high whiteness value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 17.3g of K 2 CO 3 Dissolve in 30ml of water, after the dissolution is complete, press titanium dioxide and K 2 CO 3 Titanium dioxide was added at a molar ratio of 3:1. After 5 minutes, NaCl was weighed according to 5% of the mass of the titanium dioxide and added to it. After it became a stable paste, it was dried in an oven to obtain a white mixture A;

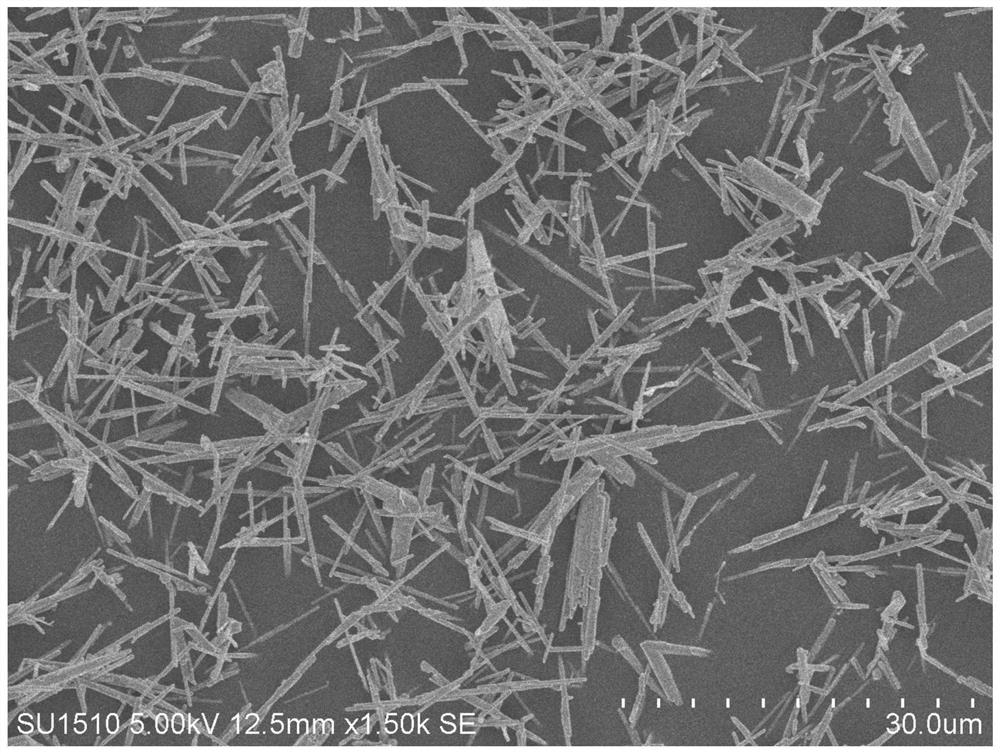

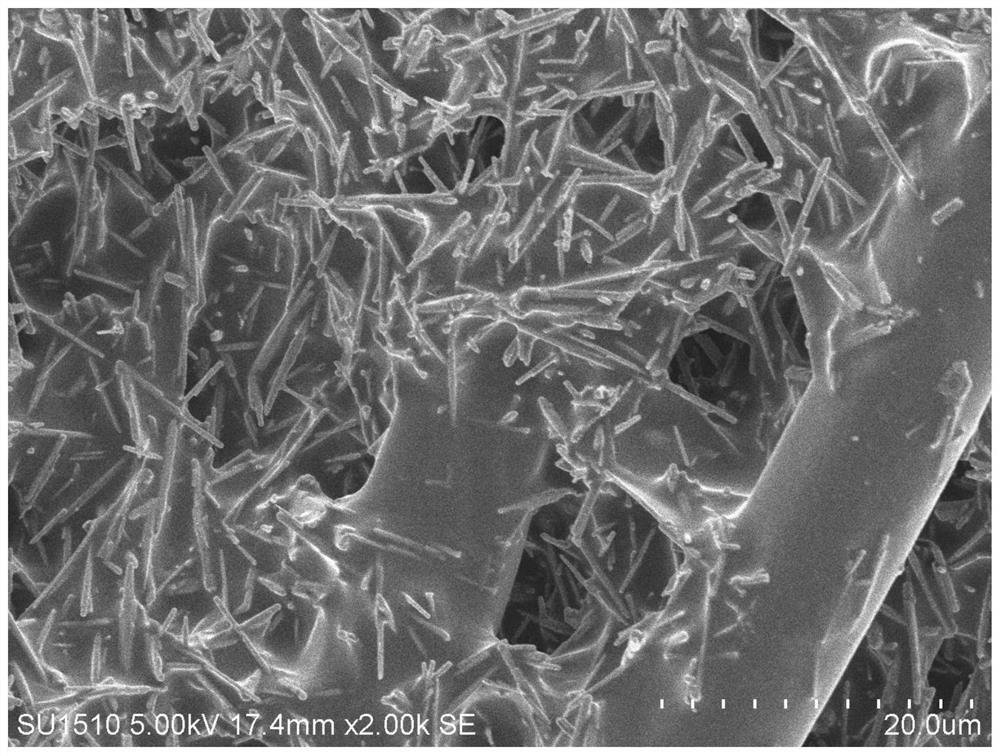

[0036] After crushing the above A, put it in a microwave sintering furnace, and sinter according to the set program. The heating rate is 20°C / min, the sintering temperature is 1000°C, and the holding time is 60min to obtain potassium tetratitanate whiskers;

[0037] After dispersing potassium tetratitanate whiskers, react them in a hydrochloric acid solution with pH=2 for 4 hours. After pickling, filter and dry the obtained solids and sinter in a microwave sintering furnace for 2 hours at a sintering temperature of 1100°C to obtain rutile TiO 2 whiskers.

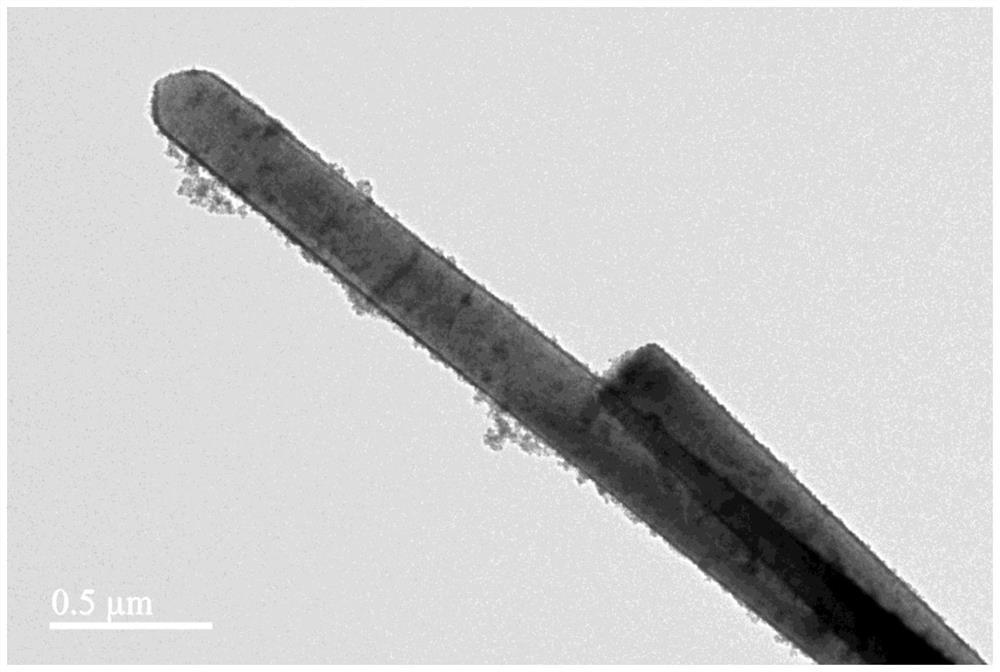

[0038] Dissolve tin fluoride and tin tetrachloride i...

Embodiment 2

[0043] Weigh 17.3g of K 2 CO 3 Dissolve in 30ml of water, after the dissolution is complete, press titanium dioxide and K 2 CO 3 Titanium dioxide was added at a molar ratio of 3:1. After 5 minutes, NaCl was weighed according to 5% of the mass of the titanium dioxide and added to it. After it became a stable paste, it was dried in an oven to obtain a white mixture A;

[0044] After crushing the above A, put it in a microwave sintering furnace, and sinter according to the set program. The heating rate is 20°C / min, the sintering temperature is 1000°C, and the holding time is 60min to obtain potassium tetratitanate whiskers;

[0045] After dispersing potassium tetratitanate whiskers, react them in a hydrochloric acid solution with pH=3 for 4 hours. After pickling, the obtained solids are filtered and dried and sintered in a microwave sintering furnace for 2 hours at a sintering temperature of 1100°C to obtain rutile TiO 2 whiskers.

Embodiment 3

[0051] Weigh 17.3g of K 2 CO 3 Dissolve in 30ml of water, after the dissolution is complete, press titanium dioxide and K 2 CO 3 Titanium dioxide was added at a molar ratio of 3:1. After 5 minutes, NaCl was weighed according to 5% of the mass of the titanium dioxide and added to it. After it became a stable paste, it was dried in an oven to obtain a white mixture A;

[0052] After crushing the above A, put it in a microwave sintering furnace, and sinter according to the set program. The heating rate is 20°C / min, the sintering temperature is 1000°C, and the holding time is 60min to obtain potassium tetratitanate whiskers;

[0053] After dispersing potassium tetratitanate whiskers, react them in a hydrochloric acid solution with pH=4 for 4 hours. After pickling, filter and dry the obtained solids and sinter them in a microwave sintering furnace for 2 hours at a sintering temperature of 1100°C to obtain rutile TiO 2 whiskers.

[0054] Dissolve tin fluoride and tin tetrachlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com