Calcium-based titanium dioxide and preparation process thereof

A calcium-based titanium dioxide, preparation process technology, applied in dyeing organosilicon compound treatment, inorganic pigment treatment, dyeing low molecular organic compound treatment and other directions, can solve the problem of low hiding power, insufficient weather resistance, and unsatisfactory achromatic performance. Satisfaction and other issues, to achieve the effect of improving whiteness, reducing production costs, and increasing added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

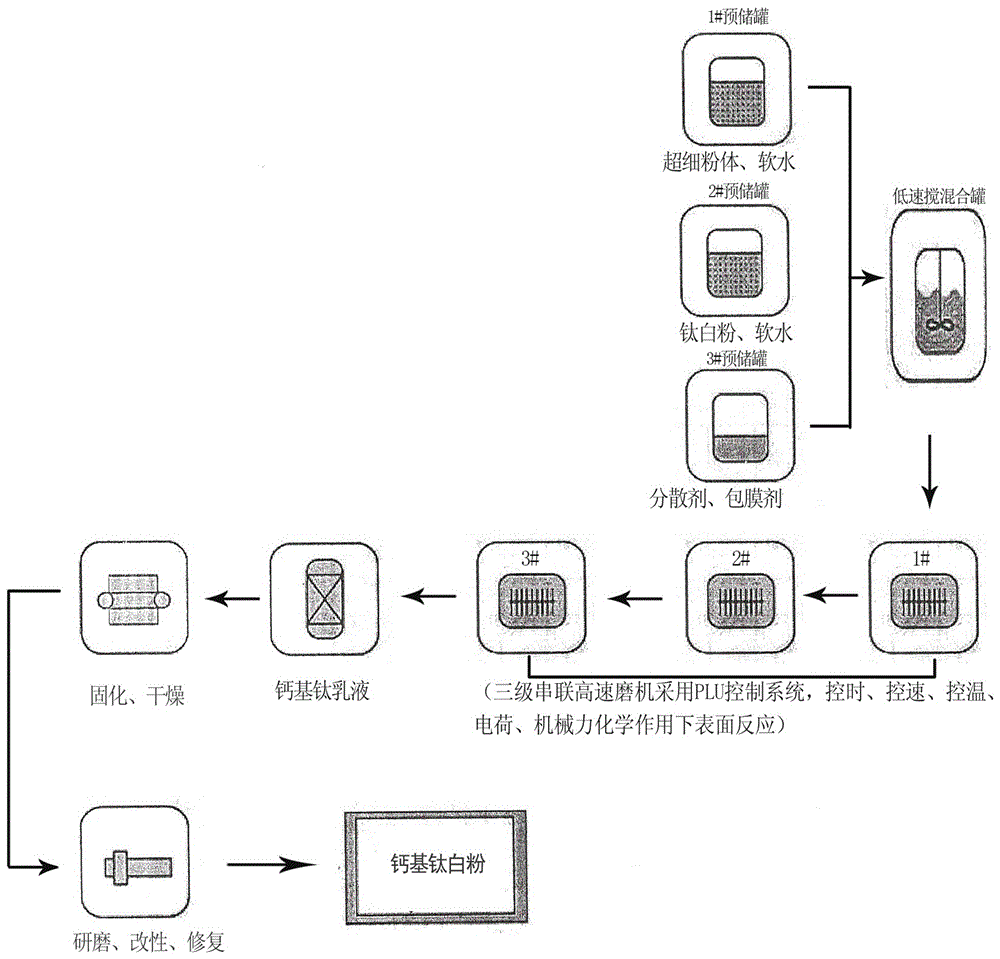

Image

Examples

Embodiment 1

[0027] Take 60 parts of 4000 mesh ultra-fine calcium carbonate powder and soft water in the ratio of 1:3 and mix them evenly in No. Storage tank, take 1 part of polycarboxylate sodium salt and 2 parts of dodecyl alcohol ester, and add soft water according to 2 times the total weight of polycarboxylate sodium salt and dodecyl alcohol ester, and mix evenly in No. storage tank; after pre-storage tanks 1, 2, and 3 are mixed evenly, they are added to the mixing reaction tank with low-speed stirring at the same time, the stirring speed is controlled at 5 rpm, and the overweight reaction is carried out for 1 hour to make the surface of the particles hydroxylated; after hydroxylation The solution is sent to a three-stage series high-speed mill, and the PLU control system is used to control the reaction. The high-speed mill is ground at a temperature of 55°C at a speed of 4500 rpm for 1.8 hours to obtain a calcium-based titanium emulsion and send it into a hot air stream Solidification...

Embodiment 2

[0029] Take 80 parts of 5000-mesh ultra-fine calcium carbonate powder and soft water in the ratio of 1:4 and mix them evenly in No. Storage tank, take 0.6 parts of polycarboxylate sodium salt and 1.5 parts of dodecyl alcohol ester, and add soft water according to 1.5 times of the total weight of polycarboxylate sodium salt and dodecyl alcohol ester, and mix evenly in No. Storage tanks; after pre-storage tanks 1, 2, and 3 are mixed evenly, add them to the mixing reaction tank with low-speed stirring at the same time, control the stirring speed at 8 rpm, and react for 1.5 hours overweight to make the surface of the particles hydroxylated; after hydroxylation The solution is sent to a three-stage series high-speed mill, and the PLU control system is used to control the reaction. The high-speed mill is ground at a temperature of 60°C and a speed of 5000 rpm for 4 hours to obtain a calcium-based titanium emulsion and send it into a hot air stream. Solidification and drying tank, fa...

Embodiment 3

[0031] Take 90 parts of 6000-mesh ultra-fine calcium carbonate powder and soft water in a ratio of 1:5 and mix them evenly in No. storage tank, take 2 parts of polycarboxylate sodium salt and 3 parts of dodecyl alcohol ester, and add soft water according to 3 times of the total weight of polycarboxylate sodium salt and dodecyl alcohol ester, and mix evenly in No. Storage tanks; after pre-storage tanks 1, 2, and 3 are mixed evenly, they are added to the mixing reaction tank with low-speed stirring at the same time, the stirring speed is controlled at 10 rpm, and the overweight reaction is carried out for 2 hours to make the surface of the particles hydroxylated; after hydroxylation The solution is sent to a three-stage series high-speed mill, and the PLU control system is used to control the reaction. The high-speed mill is ground at a temperature of 68°C and a speed of 6600 rpm for 2.2 hours to obtain a calcium-based titanium emulsion and send it into a hot air stream. Solidif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com