High-temperature heavy-load negative lead paste for start-stop battery and preparation method of negative lead paste

A battery negative electrode and heavy-duty technology, applied in the field of electrochemistry, can solve the problems of aggravated negative electrode self-discharge, difficulty in industrialization, water loss, etc., and achieve the effects of strong charge acceptance, strong operability, and low interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

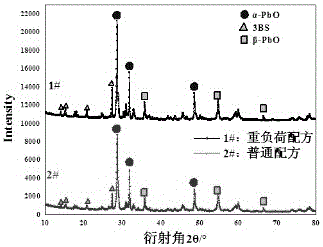

[0035] A high-temperature heavy-duty start-stop battery negative lead paste consists of the following components by weight percentage:

[0036]Density ρ=1.38g / mL dilute sulfuric acid 7% (containing 1.1% anhydrous sodium sulfate), deionized water 10%, high-performance organic additive Expander 10.1%, high-performance organic additive Expander 20.1%, conductive polyester staple fiber 0.1%, superfine precipitated barium sulfate 0.5%, carbon material additive CarbonA with high specific surface area (BET) and high oil absorption value and the main particle size distribution is concentrated in 2-5μm CarbonA0.2%, the rest is lead powder with an oxidation degree of 65% 82 %.

[0037] The above-mentioned high-temperature heavy-duty start-stop battery negative lead paste is prepared by the following steps, based on the production of 100kg of composite paste:

[0038] (1) Mechanically premix 0.1Kg of conductive polyester short fiber, 0.5Kg of barium sulfate, and 0.2Kg of CarbonA in adva...

Embodiment 2

[0045] A high-temperature heavy-duty start-stop battery negative lead paste consists of the following components by weight percentage:

[0046] Density ρ=1.38g / mL 7.5% dilute sulfuric acid (containing 1.1% anhydrous sodium sulfate), 12% deionized water, 10.15% high-performance organic additive Expander, 20.2% high-performance organic additive Expander, conductive polyester staple fiber 0.15%, superfine precipitated barium sulfate 0.8%, high specific surface area (BET), high oil absorption value and carbon material additive CarbonA0.4% with the main particle size distribution concentrated in 2-5μm, the rest is lead powder with an oxidation degree of 70% 78.8 %.

[0047] The above-mentioned high-temperature heavy-duty start-stop battery negative lead paste is prepared by the following steps, based on the production of 100kg of composite paste:

[0048] (1) Mechanically premix 0.15Kg of conductive polyester short fiber, 0.8Kg of barium sulfate, and 0.4Kg of CarbonA in advance ac...

Embodiment 3

[0055] A high-temperature heavy-duty start-stop battery negative lead paste consists of the following components by weight percentage:

[0056] Density ρ=1.38g / mL 7.5% dilute sulfuric acid (containing 1.2% anhydrous sodium sulfate), 10% deionized water, 10.2% high-performance organic additive Expander, 20.4% high-performance organic additive Expander, conductive polyester staple fiber 0.2%, superfine precipitated barium sulfate 1.0%, carbon material additive CarbonA with high specific surface area (BET) and high oil absorption value and the main particle size distribution is concentrated in 2-5μm CarbonA0.6%, the rest is lead powder with an oxidation degree of 80% 80.1 %.

[0057] The above-mentioned high-temperature heavy-duty start-stop battery negative lead paste is prepared by the following steps, based on the production of 100kg of composite paste:

[0058] (1) Mechanically premix 0.2Kg of conductive polyester short fiber, 1.0Kg of barium sulfate, and 0.6Kg of CarbonA in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com