A method for preparing schistose nanometer magnesium hydroxide and sphericity nanometer white carbon black using zillerite gangue

A technology of nano-magnesium hydroxide and nano-white carbon black, applied in the direction of magnesium hydroxide, silicon oxide, silicon dioxide, etc., can solve the problems of comprehensive utilization rate and low product grade, single extraction or utilization, etc., and achieve dispersibility and The effect of good surface activity, good product quality and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

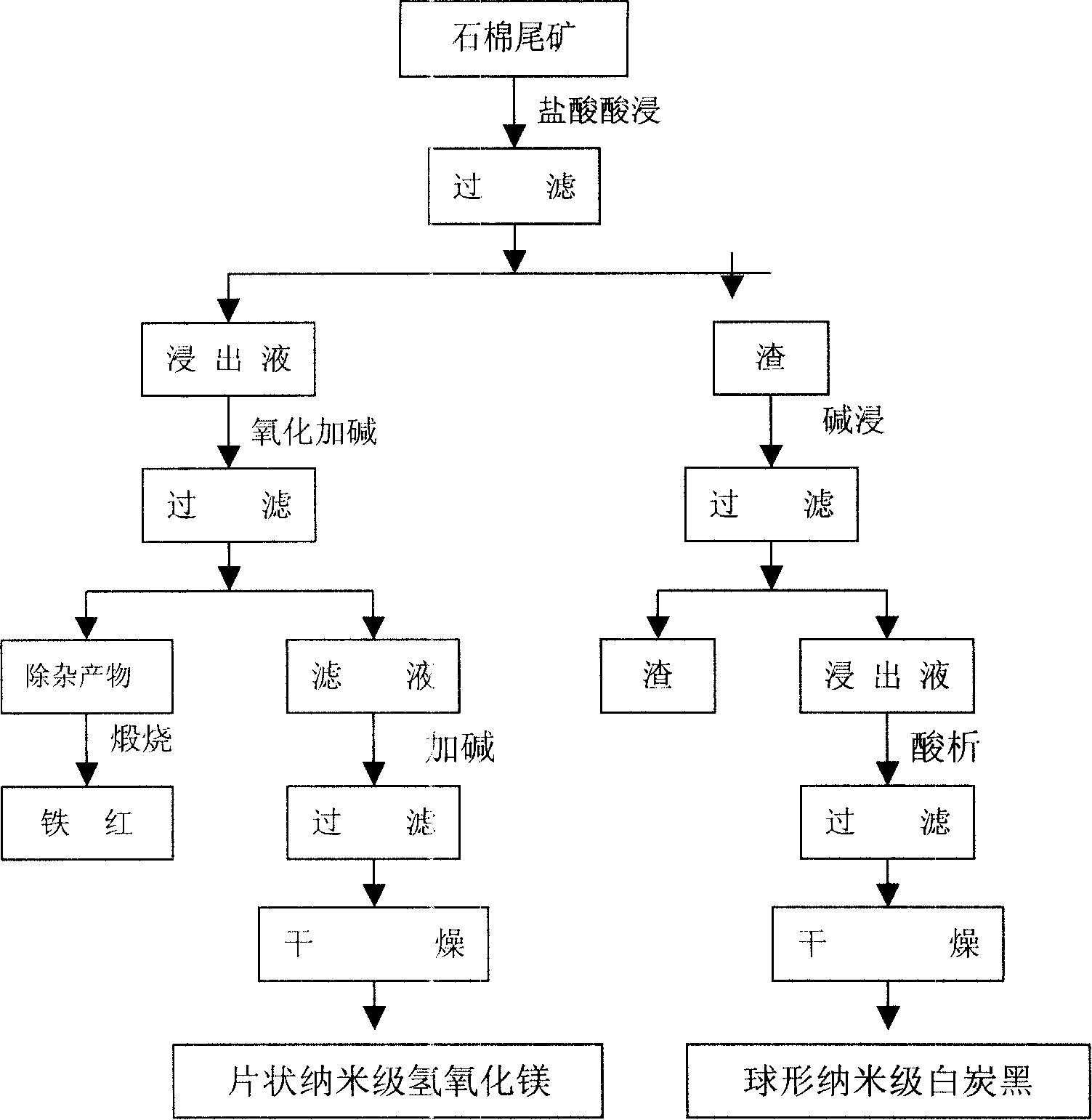

Method used

Image

Examples

Embodiment 1

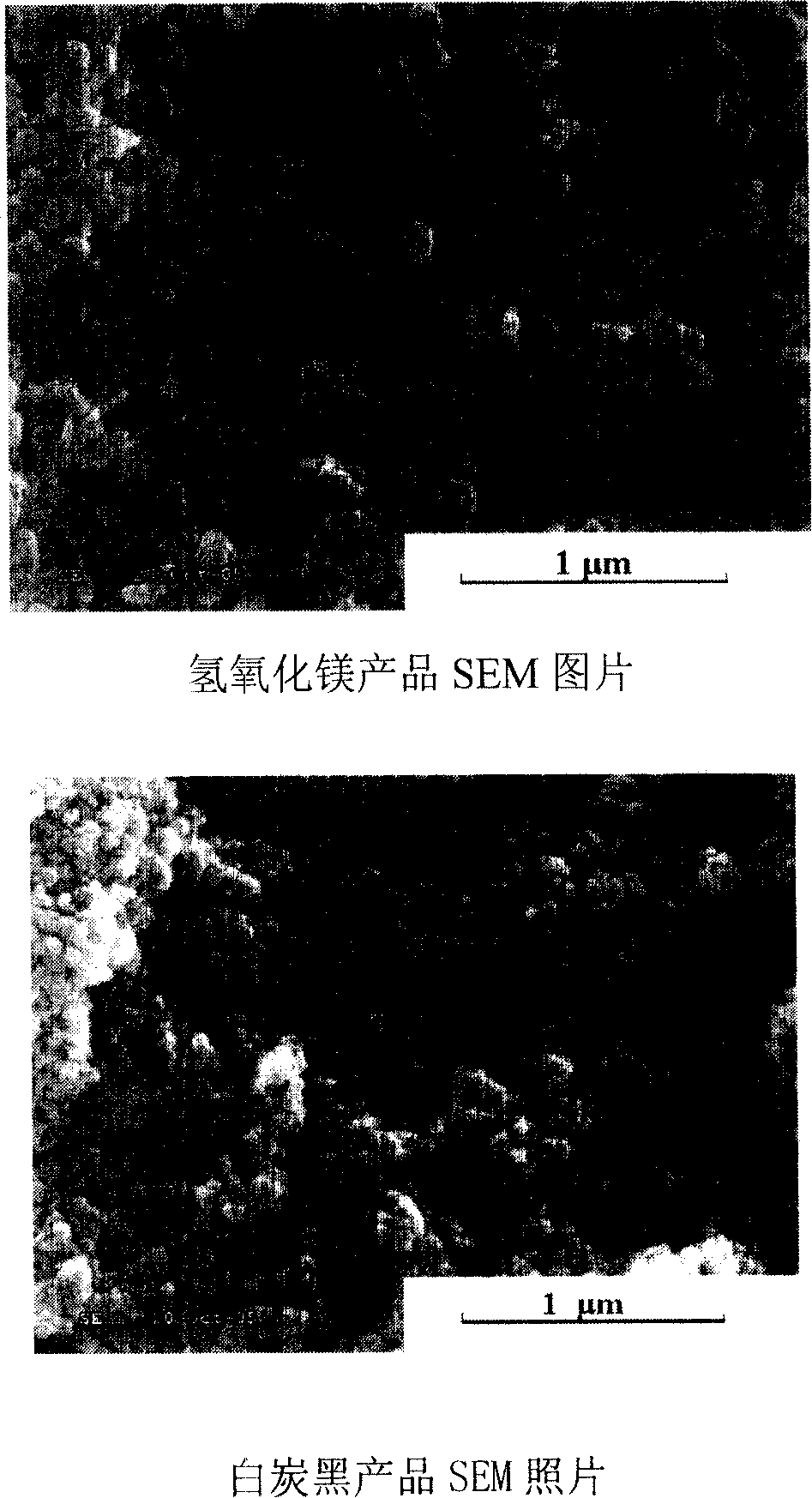

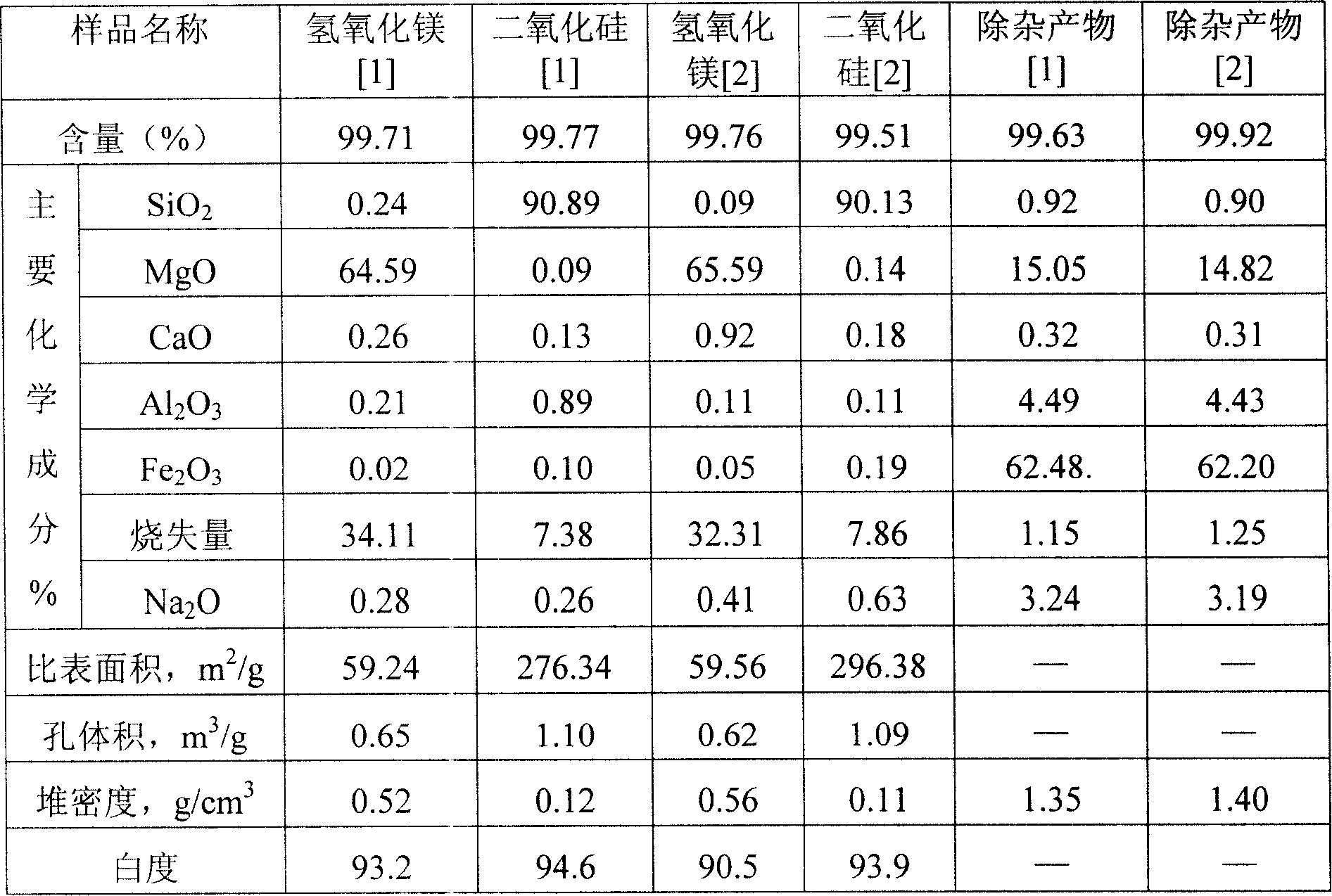

[0045] Get 100g of asbestos tailings powder, add 219g concentration of 37% hydrochloric acid, add water 75ml, react at 95°C for 1.5h; separate solid-liquid components after filtration; React at 80°C for 15 minutes, add sodium hydroxide solution to adjust the pH of the system to 6.5, and age for 30 minutes; after filtering and separating the precipitate, adjust the Baume degree of the solution to 20°, add 0.11 g of polyethylene glycol, Add dropwise sodium hydroxide solution for precipitation reaction for 5 minutes until the pH value of the system is 13. After aging for 50 minutes, filter, wash and dry to obtain the flaky nano-sized magnesium hydroxide product.

[0046] Add 11.66g of 26.4g of solid sodium hydroxide to the acid leaching residue, add 87ml of water, stir and react at 85°C for 1h, filter out the residue, add water to adjust the Baume degree of the filtrate to 20°, add 3g of anhydrous sodium sulfate and add 6.0% silane coupling agent SCA-1613, add sulfuric acid with ...

Embodiment 2

[0048] Put 150kg of asbestos tailings, 392kg of hydrochloric acid with a mass concentration of 31%, and 93kg of water into the reaction kettle, heat and control the temperature between 95°C and 110°C for 1.5h. Then, the solid and liquid components were separated by filtration. The Baume degree of the leaching solution was adjusted to 18°, the temperature was controlled at 65, and 5.18 kg of hydrogen peroxide with a mass concentration of 30% was used for oxidation treatment for 15 minutes. Start to add alkali after the completion of the reaction, the mass concentration of sodium hydroxide solution used is 20%, the time for adding alkali is 3 minutes, the amount of alkali used is 200L, and aging for 25 minutes after the reaction. After the reaction, the pH value of the filtrate is 5 to 6. The solid-liquid system after the reaction is separated by filtration, and the obtained precipitate is calcined at 700° C. to obtain a mixture whose main components are iron oxide, magnesium o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com