Preparation method of novel core-shell type cement-based high-strength lightweight aggregate

A lightweight aggregate and cement-based technology, applied in the field of building materials, can solve the problems of poor corrosion resistance of steel bars, inconspicuous thermal insulation effect, low particle strength, etc., to achieve improved seismic performance, exempt from external insulation construction technology, and high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

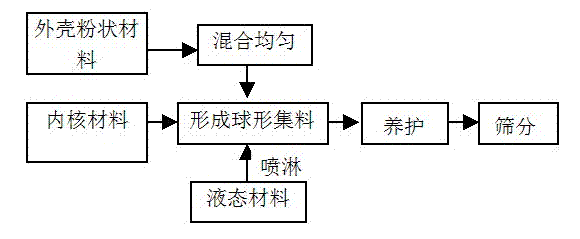

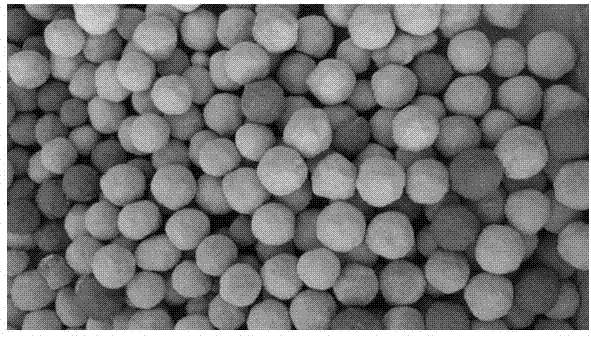

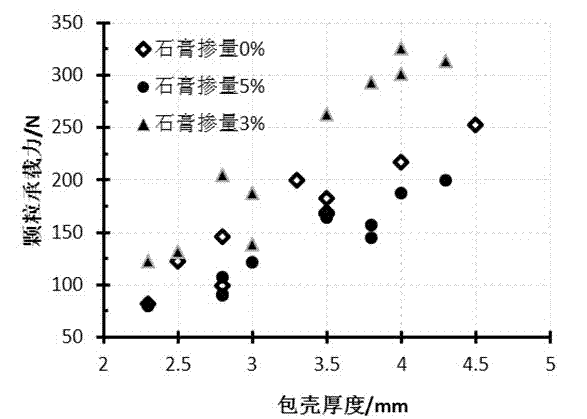

[0023] The technical scheme of the present invention is: mainly use light materials such as expanded perlite powder, polystyrene particles, and light waste particles as core materials, and mix cement, admixtures, admixtures and water to form a single-layer or multi-layer The shell material is a cement-based high-strength lightweight aggregate with specific functions, which is made of a ball-forming process without burning the shell and cured. The material can belong to the category of cement-based composite materials, and to some extent also belongs to the category of unfired ceramsite. It is characterized by:

[0024] (1) The raw material adopts a spherical or granular core material (expandable EPS particles) and a shell material attached to the outside of the core.

[0025] The core material is one or more of light materials such as expanded perlite powder, polystyrene particles, light waste particles, etc.; surface modified EPS particles and light waste particles can be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com