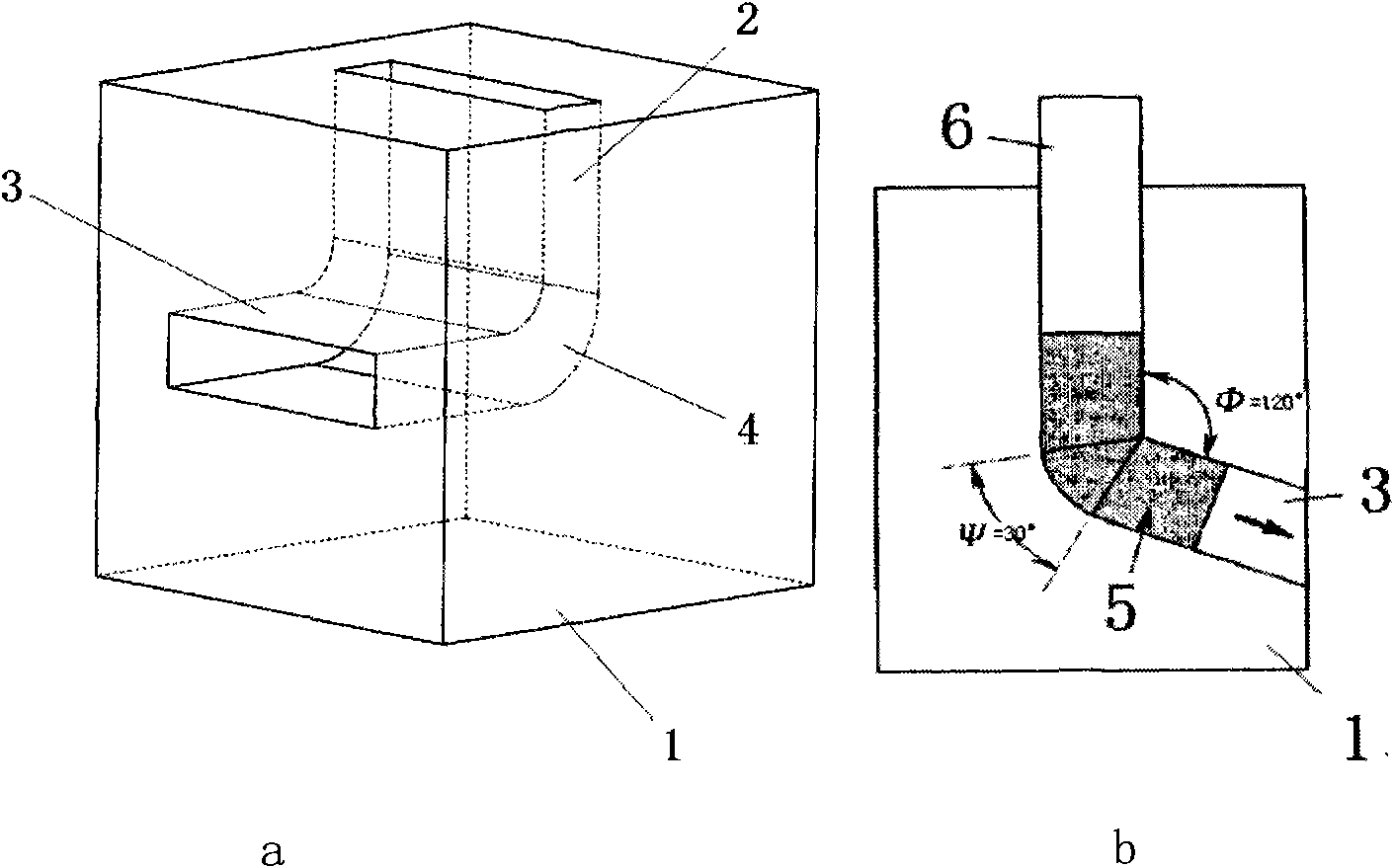

Preparation method of ultra-pure aluminum ultrafine grain sputtering target

A technology of ultra-fine grains and sputtering targets, which is applied in sputtering plating, metal material coating process, ion implantation plating, etc., and can solve the problems of slow recrystallization process, difficult refinement, difficult materials, etc. Achieve the effects of large deformation, increased deformation, uniform and fine grain shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0027] Example 2: Using the same steps as in Example 1, when equal-channel extrusion is carried out for 8 passes, deep subcooling is performed to -50°C, and rolling is performed for 8 passes, the final ultra-high-purity aluminum target grains obtained The size can reach below 200μm.

Embodiment 3

[0028] Example 3: Using the same steps as in Example 1, when 15 passes of equal channel extrusion, deep supercooling treatment to -80°C, and 15 passes of rolling, the final ultra-high-purity aluminum target grains obtained The size can reach below 100μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com