On-line aggregate monitoring device

A detection device and aggregate technology, applied in measurement devices, particle size analysis, scientific instruments, etc., can solve the problems affecting particle size detection accuracy, aggregate particle size and particle shape cannot be detected at the same time, time-consuming, etc. Processing and analysis, the analysis algorithm is simple and reliable, and the effect of avoiding economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

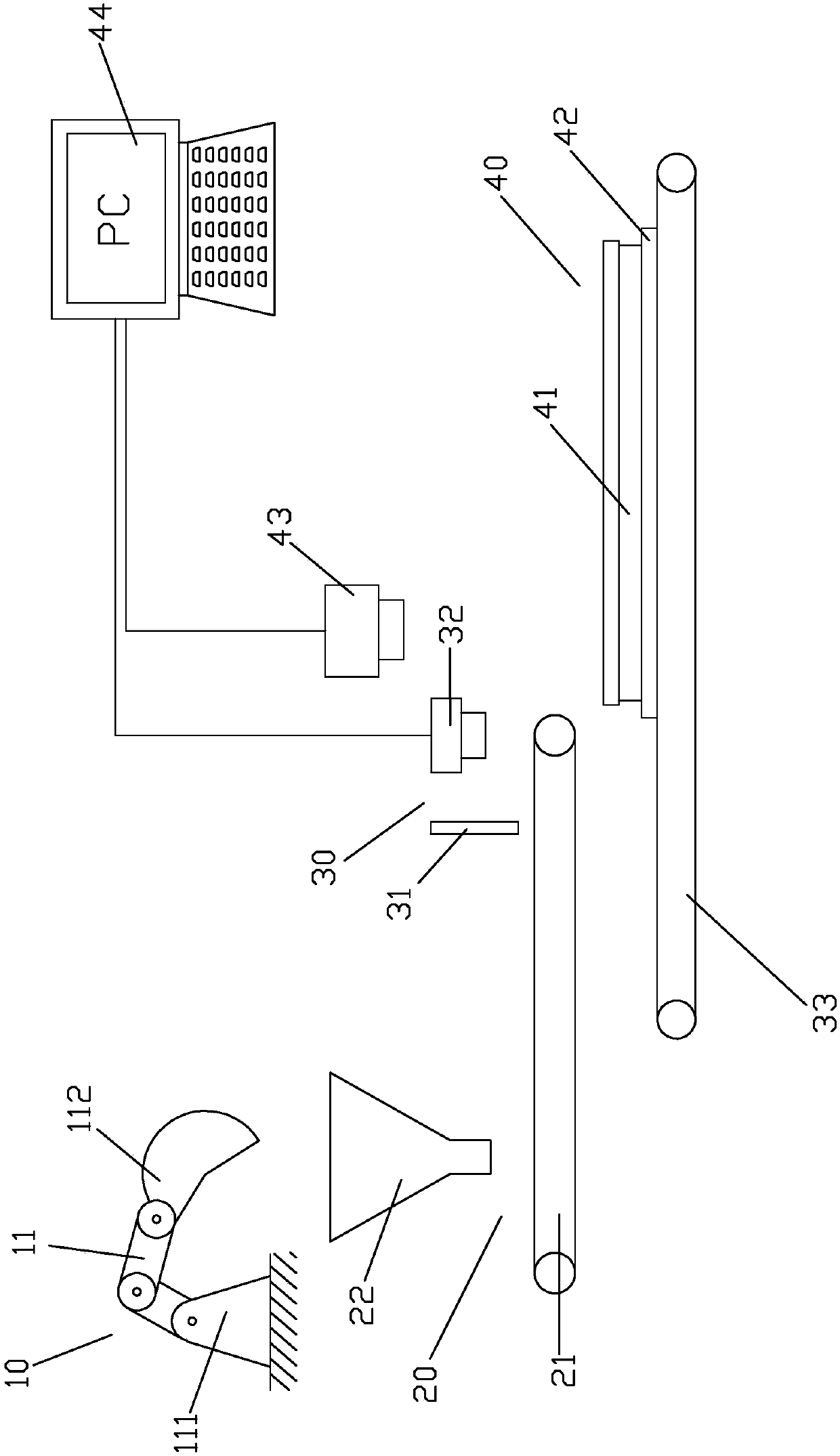

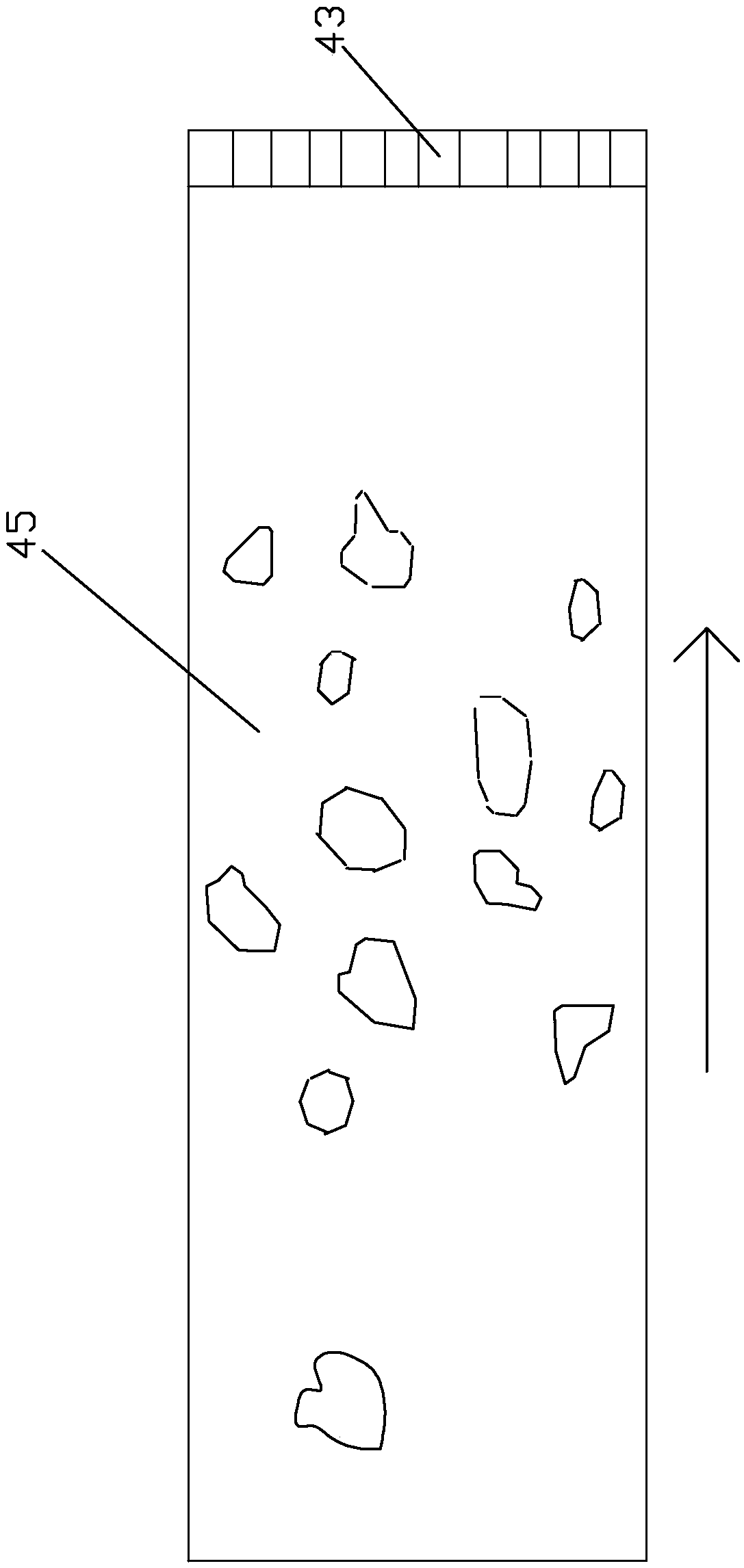

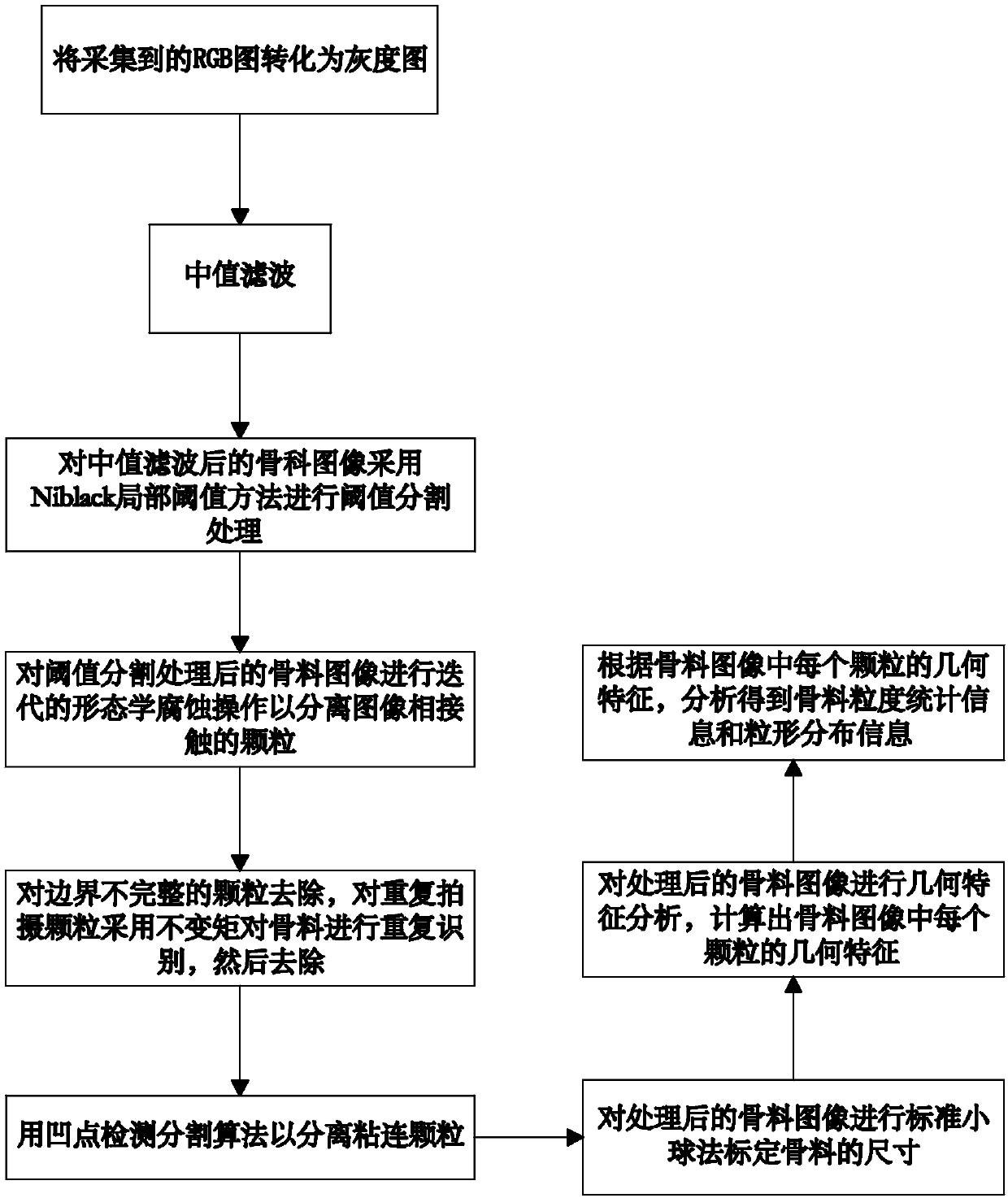

[0039] Please check figure 1 , the present invention provides an aggregate online detection device, comprising a sampling module 10, a sampling module 20, a dispersion module 30, and an image acquisition and analysis module 40; Sampling is carried out frequently, and sent to the sampling module 20, and then reaches the image acquisition area of the image analysis module 40 through the dispersion module 30, and the image acquisition area analysis module 40 performs feature extraction on the collected images to obtain aggregate parameters.

[0040] The sampling module 10 of the present invention is an automatic sampling manipulator 11, which is arranged above the feeding conveyor belt 21. Specifically, the automatic sampling machine manipulator includes a mechanical platform 111 and a mechanical arm 112, and the mechanical arm 112 samples at a preset frequency. Aggregate is put into sampling module 20.

[0041] The sampling module 20 of the present invention also includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com